HTAN ist einer der führenden Hersteller von industriellen Scharnieren, Griffen und Verschlüssen in China.

-

+86 13720060320

-

julius@haitangs.com

Warum ist der Griff aus Edelstahl 304 die bevorzugte Wahl in allen Branchen?

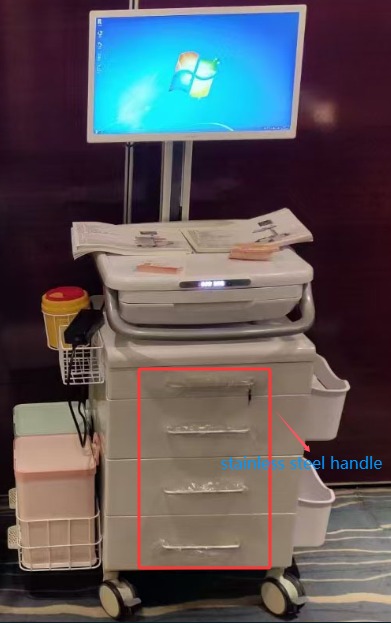

In the kitchen, medical and industrial fields, the performance of metal handles directly affects the safety and service life of equipment. 304 stainless steel handles have occupied 75% of the global market for medium and high-end Griffe due to its corrosion resistance, high strength and easy-to-clean characteristics. Its stable physical properties and hygienic advantages, an effective alternative to traditional metal materials, and become the preferred solution in the field of precision manufacturing.

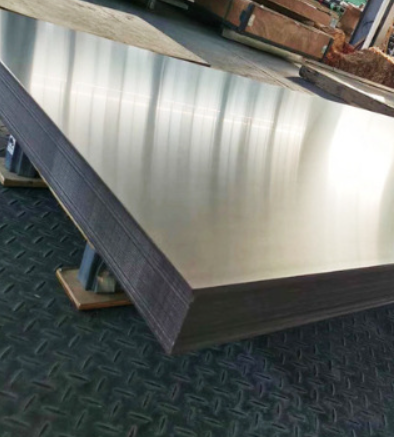

About 304 stainless steel

304 stainless steel belongs to the general-purpose austenitic stainless steel, with corrosion resistance and high temperature stability, widely used in industry, commerce, construction and other industries.

Verhältnis der Hauptelemente (Massenprozent)

| Element | Inhaltsbereich (Massenprozent) | Rolle |

|---|---|---|

| Chrom (Cr) | 18.0% - 20.0% | Bildung einer Schutzschicht aus Chromoxid, die für Korrosionsbeständigkeit sorgt |

| Nickel (Ni) | 8.0% - 10.5% | Stabilisiert die Austenitstruktur, verbessert die Duktilität, die Hochtemperaturleistung und die Korrosionsbeständigkeit |

| Kohlenstoff (C) | ≤ 0,08% | Niedriger Kohlenstoff reduziert Karbidausscheidungen und verbessert die Schweißbarkeit (304L: ≤ 0,03%; 304H: ≥ 0,04%) |

| Mangan (Mn) | ≤ 2.0% | Verbesserung der Kraft und der Aushärtungsfähigkeit |

| Silizium (Si) | ≤ 1,0% | Erhöhte Oxidationsbeständigkeit und Hochtemperaturfestigkeit |

| Phosphor (P) | ≤ 0,045% | Verunreinigungen, die streng kontrolliert werden müssen, um die Zähigkeit der Materialien zu erhalten |

| Schwefel (S) | ≤ 0,030% | Verunreinigungen, ein Überschuss verringert die Korrosionsbeständigkeit und die Verarbeitungsleistung |

| Eisen (Fe) | Bilanz | als Basismetall den Hauptteil der Legierung bilden |

| Stickstoff (N) | ≤ 0,10% (Spur) | können in geringen Mengen vorhanden sein, sind aber nicht die wichtigsten zugesetzten Elemente |

| Molybdän (Mo) | Normalerweise nicht vorhanden | Die molybdänhaltige Version ist aus 316er Edelstahl (höhere Korrosionsbeständigkeit) |

This ratio allows the material to form a stable austenitic structure with the following distinctive features:

- Non-magnetic characteristics: will not interfere with medical equipment and precision instruments

- Corrosion resistance: 5-8 times higher than ordinary steel

- Mechanical strength: tensile strength reaches more than 520MPa

We commonly see this silver-white metal in food processing equipment, medical equipment, building decoration and other scenes. Especially in occasions that require frequent contact with water vapor and chemical reagents, 304 stainless steel handles can maintain long-term stability.

Analysis of the four core advantages

Super anti-rust ability

Ordinary carbon steel handle in the wet environment in a few weeks that is rust, and 304 stainless steel handle through the 3 nano chromium oxide passivation film to achieve self-repairing protection, scratches can be regenerated after contact with oxygen protective layer. After surface treatment, its salt spray test corrosion resistance up to 200 hours, far more than the industrial standard.

Excellent mechanical properties

Comparative experiments show that:

- Zugfestigkeit: 304 stainless steel (520MPa) vs 201 stainless steel (380MPa)

- Elongation: 304 stainless steel (40%) vs aluminum alloy (15%)

This makes 304 stainless steel handle can withstand heavy loads, but also for complex modeling processing. Through stamping, bending and other processes, you can create an ergonomic shaped handle.

Convenient processing characteristics

The practical application on the production line shows:

- Welding pass rate up to: 99.2

- Surface roughness: Ra0.05μm after polishing.

This feature allows manufacturers to mass produce a variety of surface effects such as mirror, brushed, sandblasted and other handle products.

Health and safety advantages

In the medical field testing, 304 stainless steel handle surface bacterial residue is only 1/20 of plastic products, smooth surface to avoid microbial breeding, wipe with alcohol can be completed disinfection. This is why surgical instruments and pharmaceutical equipment are mandatory to use this type of material.

304 stainless steel handle application scenarios

Kitchen equipment

From household induction cookers to commercial baking equipment, 304 stainless steel handles solve three key problems:

- Resistant to high temperatures from 150°C to 300°C

- Prevent corrosion by dishwasher detergent

- Withstand repeated lifting and pulling of pots and pans

Medical field

Hospital environments have special requirements for materials:

- Withstand high temperature and high pressure sterilization more than 20 times a week

- No reaction with sterilization agents

- No crevices on the surface to hide dirt

Stamped 304 stainless steel handles meet these exacting standards and have a service life of more than 10 years.

Industrial Manufacturing

In automobile production lines, chemical plants and other places, the equipment handle needs to:

- Withstand engine oil, cutting fluid and other chemicals

- Work properly in temperatures ranging from -20°C to 80°C

- Prevent corrosion by workers’ sweat

Material comparison guide

Comparison with 201 stainless steel

Although the 201 material is 30% cheaper, its corrosion resistance only reaches 40% of 304. Comparative tests in coastal cities show that 201 stainless steel handles show rust spots in 6 months, while 304 products remain intact for 3 years.

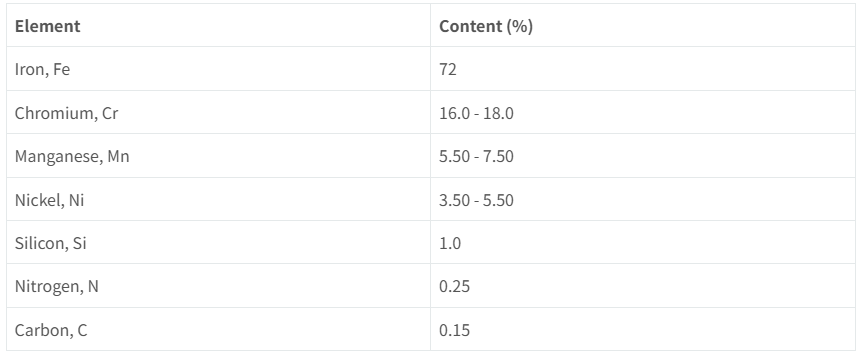

The following table shows the chemical composition of grade 201 stainless steel.

Comparison with 316 Stainless Steel

The 316 model has 2% molybdenum added, making it more suitable for marine environments. However, for most inland application scenarios, 304 stainless steel handles are more cost effective. The price difference between the two is usually more than 50%.

Composition ranges for 316 grade of stainless steels.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 316 | Min | – | – | – | 0 | – | 16.0 | 2.00 | 10.0 | – |

| Max | 0.08 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

| 316L | Min | – | – | – | – | – | 16.0 | 2.00 | 10.0 | – |

| Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

| 316H | Min | 0.04 | 0.04 | 0 | – | – | 16.0 | 2.00 | 10.0 | – |

| max | 0.10 | 0.10 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | – |

Comparison with Plastic/Aluminum

- Plastic handles will deform above 80°C

- Aluminum alloy is prone to oxidized white spots after long-term use

- Stainless steel is 3-5 times stronger than both.

Maintenance Recommendations

- Regularly wipe with neutral detergent

- Avoid contact with strong acids and alkalis (e.g. toilet bowl cleaner)

- Check if the mounting screws are loose

- Monthly maintenance is recommended for seaside environments

Special note: Do not use steel wool for cleaning as this will damage the protective oxide layer.

Schlussfolgerung

304 stainless steel handle with corrosion resistance, high strength and easy to clean characteristics, widely used in the medical, kitchen and industrial fields, its stability and hygiene advantages far beyond the plastic, aluminum alloy and other materials, cost-effective than other stainless steel, become the first choice for precision manufacturing solutions.