HTAN est l'un des principaux fabricants de charnières, de poignées et de loquets industriels en Chine.

Dans l'équipement industriel, le mobilier de bureau et les systèmes de stockage haut de gamme, poignées encastrées remplacent rapidement les systèmes d'information traditionnels. poignées externesLes poignées encastrées deviennent un élément clé pour améliorer la fonctionnalité et l'esthétique. Cet article analyse les principes structurels, les scénarios d'application et les stratégies de sélection des poignées encastrées afin de vous aider à optimiser les solutions de portes d'armoires en termes de praticité et d'attrait visuel.

Table des matières

ToggleQu'est-ce qu'une poignée encastrée ?

A Poignée encastrée est un composant de précision conçu pour être complètement encastré dans la surface de la porte de l'armoire. Son bord extérieur conserve une tolérance plane de ≤ 0,5 mm avec le panneau de la porte, réalisant une intégration transparente à la fois visuelle et tactile.

Différence entre les poignées extérieures encastrées et traditionnelles

| Dimension de comparaison | Poignée encastrée | Poignée extérieure |

|---|---|---|

| Méthode d'installation | Encoche dans le panneau de porte | Fixation par boulons en surface |

| Occupation de l'espace | Convexité zéro | saillie de 15 à 30 mm |

| Difficulté de nettoyage | Facile à essuyer, pas d'espace mort | Sujet à l'accumulation de poussière, nécessite un démontage pour le nettoyage |

| Coût de fabrication | Usinage de haute précision (±0,1 mm) | Usinage conventionnel |

Composants essentiels et structure des poignées encastrées

1. Composants principaux

Corps de la poignée :

- Matériau: Alliage d'aluminium, acier inoxydable 304 (résistant à la corrosion), plastique technique POM (isolant)

- Processus: Usinage de précision CNC (anodisation de surface/sablage)

Structure de soutien intégrée :

- Portes d'armoires robustes: Squelette renforcé en acier (charge admissible ≥ 50kg)

- Portes d'armoires légères: Siège fixe à encliquetage en nylon

Interface d'installation :

- Type standard: Trous filetés M4/M5, pas 50mm/80mm

- Adaptation rapide: Conception de la pince à ressort, réduisant le temps d'installation de 70%

2. Principales considérations en matière de conception

- Vérification de la solidité: 10 000 cycles d'essais de fatigue à l'ouverture et à la fermeture

- Adaptation à l'environnement: Essai au brouillard salin ≥ 720 heures

Avantages des poignées encastrées

- Intégration transparente: Le design encastré assure un aspect moderne et minimaliste.

- Peu encombrant: Élimine les saillies, réduisant ainsi l'occupation de l'espace.

- Sécurité renforcée: Prévient les accidents causés par les poignées saillantes, en réduisant les risques de chocs et d'accrochages.

- Haute durabilité: Fabriqués à partir de matériaux très résistants tels que l'alliage d'aluminium, l'acier inoxydable et les plastiques techniques, ils offrent une excellente résistance à l'usure et à la corrosion.

Scénarios d'application des poignées encastrées

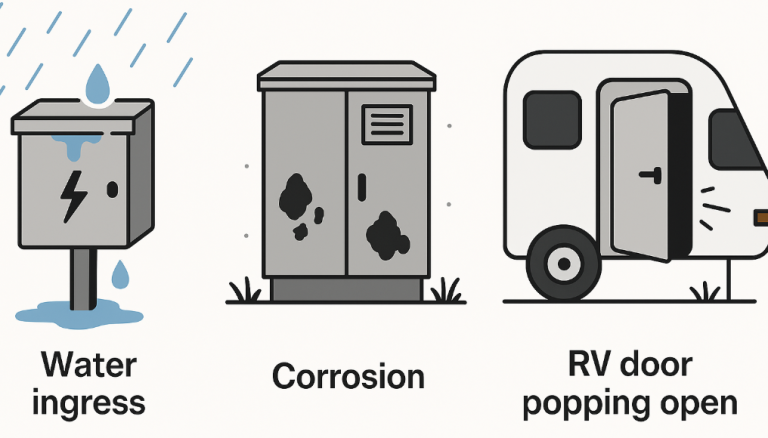

- Armoires de commande industrielles et armoires électriques: Couramment utilisé pour les panneaux de porte.

- Matériel d'entreposage: Installé dans des étagères, des boîtes de stockage et des conteneurs logistiques.

- Enceintes de machines: Utilisé sur les carters de machines ou les panneaux latéraux pour faciliter l'accès.

Guide d'installation des poignées encastrées

1. Préparation à l'installation

- Outils et matériaux: Tournevis, outil de coupe, mètre ruban, vis de fixation ou clips.

- Confirmation du positionnement: Marquer l'emplacement de l'installation selon les dessins de conception pour assurer une hauteur de fonctionnement ergonomique.

2. Coupe de précision

- Mesure et marquage: Utilisez un mètre ruban pour marquer les dimensions de la porte de l'armoire, avec une marge d'erreur de ≤1mm.

- Opération de coupe: Utiliser une rogneuse pour couper le long de la marque, puis lisser les bords pour éviter les bavures.

3. Installation et fixation

- Insertion de la poignée: Aligner les trous et enfoncer la poignée dans la fente, en vérifiant la planéité des angles.

- Fixation: Fixer avec des vis.

Principales notes d'installation :

- Étanchéité à l'eau: Appliquer du silicone neutre sur les joints pour les environnements extérieurs ou humides.

- Mesures de sécurité: Porter des gants et des lunettes résistant aux coupures ; nettoyer rapidement les débris.

Guide de sélection des matériaux

| Exigence | Matériau recommandé |

| Résistance à la corrosion | Acier inoxydable 316L > Alliage d'aluminium anodisé > Acier galvanisé |

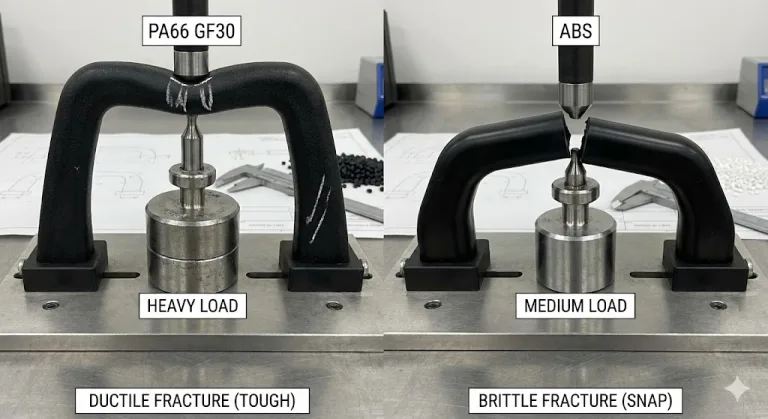

| Demande légère | Fibre de carbone > Alliage d'aluminium 6061 > Plastiques techniques PEEK |

| Applications sensibles aux coûts | Plastique ABS > acier laminé à froid > matériaux composites |

FAQ

A : Optez pour des modèles dont la structure est renforcée par de l'acier et qui supportent jusqu'à 80 kg par point.

A: Appliquer de la colle à filetage pour fixer les boulons et vérifier la force de pré-tension tous les six mois.

R : Il y a l'acier inoxydable, l'alliage de zinc, l'alliage d'aluminium, les plastiques techniques, etc.

R : La poignée encastrée en acier inoxydable présente une bonne résistance à la corrosion.

A:Différents matériaux, la capacité de charge est différente, en fonction du matériau et des instructions de l'entreprise.

Conclusion

En tant qu'innovation importante dans la conception des portes d'armoires, la poignées encastrées sont fabriqués à partir d'un usinage CNC de haute précision et de métaux et plastiques techniques de haute qualité afin de garantir une résistance à l'abrasion et à la corrosion et de répondre à la demande de chargement de portes d'armoires à usage intensif.

Les fabricants devraient donner la priorité ISO 9001-fournisseurs certifiés et demander Rapports d'essais d'ajustement du modèle 3D.

HTAN Fondée en 2015, la société se concentre sur la recherche, le développement et la production de composants d'armoires industrielles. Elle possède des usines indépendantes d'une superficie de 7 000 mètres carrés et des douzaines d'employés. brevetsSi vous avez des problèmes avec l'extracteur intégré, veuillez me contacter.

Anson Li

Bonjour à tous, je m'appelle Anson Li. Je travaille dans le secteur des charnières industrielles depuis 10 ans ! Tout au long de mon parcours, j'ai eu la chance de travailler avec plus de 2 000 clients de 55 pays, concevant et produisant des charnières pour toutes sortes de portes d'équipement. Nous avons grandi avec nos clients, nous avons beaucoup appris et nous avons acquis une expérience précieuse. Aujourd'hui, j'aimerais partager avec vous quelques conseils et connaissances professionnels sur les charnières industrielles.

通讯更新

在下面输入您的电子邮件地址并订阅我们的新闻通讯

POSTES CONNEXES

Sélection des charnières d'armoires électriques et gestion des fournisseurs

- 800 次浏览

Charnières d'ordinateurs portables sur mesure : Conception structurelle, amortissement et optimisation des matériaux

- 1219 次浏览

Acheter des poignées en acier inoxydable Fournisseur Contact

- 765 次浏览

Le guide ultime des loquets à palette pour l'extérieur et les environnements difficiles

- 72 次浏览

Sélection de poignées industrielles en plastique : PA66 vs. ABS & Test de charge

- 93 次浏览

Principaux avantages des charnières à ressort amovibles pour des applications flexibles et stables

- 857 次浏览