HTAN est l'un des principaux fabricants de charnières, de poignées et de loquets industriels en Chine.

L'acier inoxydable 304 est un acier à usage général tache austénitiquemoins d'acier. Il se compose de plus de 18% de chrome (Cr) et de plus de 8% de nickel (Ni), avec de petites quantités de carbone, de manganèse et d'autres éléments. Ce matériau est largement reconnu comme l'un des types d'acier inoxydable les plus courants, représentant plus de 30% de tout l'acier inoxydable consommé dans le monde sur une base annuelle.

Pourquoi est-elle la plus fréquente ?

- Rentable : par rapport à ceux contenant du molybdène Acier inoxydable 316, 304 est moins cher à produire

- Large éventail d'applications : de l'équipement de transformation des aliments à la décoration architecturale

- Bonne aptitude à la transformation : convient à l'emboutissage, au soudage, au pliage, etc.

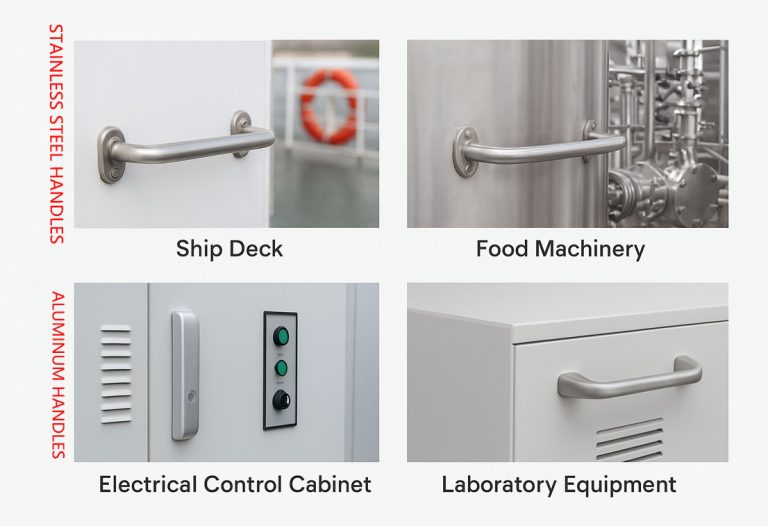

Aperçu des secteurs d'activité

- Industrie alimentaire et des boissons : les équipements exposés à des liquides acides ou à des vapeurs à haute température, etc.

- Matériel médical : instruments chirurgicaux, ustensiles stérilisés, etc.

- Équipement industriel : charnières électriques pour armoiresles carters de machines, etc.

- Décoration des bâtiments : mains courantes, supports pour murs-rideaux, etc.

Composition chimique de l'acier inoxydable 304

Rapport des éléments majeurs (pourcentage de masse)

| Élément | Plage de contenu (pourcentage de masse) | Rôle |

|---|---|---|

| Chrome (Cr) | 18.0% – 20.0% | Formation d'une couche protectrice d'oxyde de chrome, assurant la résistance à la corrosion |

| Nickel (Ni) | 8.0% – 10.5% | Stabilise la structure de l'austénite, améliore la ductilité, les performances à haute température et la résistance à la corrosion. |

| Carbone (C) | ≤ 0,08% | La faible teneur en carbone réduit la précipitation de carbure et améliore la soudabilité (304L : ≤ 0,03% ; 304H : ≥ 0,04%). |

| Manganèse (Mn) | ≤ 2.0% | Amélioration de la résistance et de la capacité d'écrouissage |

| Silicium (Si) | ≤ 1.0% | Amélioration de la résistance à l'oxydation et de la résistance aux températures élevées |

| Phosphore (P) | ≤ 0,045% | Les éléments d'impureté doivent être strictement contrôlés pour maintenir la ténacité des matériaux. |

| Soufre (S) | ≤ 0,030% | Éléments d'impureté dont l'excès réduit la résistance à la corrosion et les performances de traitement |

| Fer (Fe) | équilibre | comme métal de base, constituent le corps principal de l'alliage |

| Azote (N) | ≤ 0,10% (trace) | peuvent être présents en petites quantités, mais ne sont pas les principaux éléments ajoutés |

| Molybdène (Mo) | Généralement absente | La version contenant du molybdène est en acier inoxydable 316 (meilleure résistance à la corrosion). |

Caractéristiques des produits sans molybdène

- Résistance à la corrosion par les chlorures plus faible que celle de l'acier inoxydable 316

- Réduction des coûts d'environ 20-30%

- Mieux adapté aux environnements non marins

Effet de la composition sur les propriétés

- Teneur élevée en chrome : crée une couche dense d'oxyde de chrome sur la surface, empêchant toute corrosion ultérieure.

- Nickel : garantit que le matériau reste résistant aux basses températures (peut résister à -196°C)

- Conception à faible émission de carbone : réduit le risque de corrosion intergranulaire après le soudage

Propriétés mécaniques de l'acier inoxydable 304

Indicateurs de performance

| Indicateur | Valeurs typiques (état recuit) | Remarques |

|---|---|---|

| Résistance à la traction | 515 - 620 MPa | Haute résistance équilibrée avec une bonne plasticité, convient pour les composants structurels. |

| Limite d'élasticité | 205 - 310 MPa | Limite d'élasticité à 0,2% de déformation résiduelle, qui peut être considérablement augmentée après un travail à froid (par exemple ≥1000 MPa après un laminage à froid). |

| Élongation | ≥ 40% (50 mm) | Grande ductilité, convient à l'emboutissage, au cintrage et à d'autres traitements. |

| Dureté | Brinell (HB) : ~201 | Faible dureté à l'état recuit, la dureté augmente après l'écrouissage (par exemple HRB 90 à l'état recuit, HRB 200+ après laminage à froid). |

| Résistance aux chocs (Impact) | à température ambiante ≥ 100 J (essai d'impact Charpy) | La structure austénitique offre une bonne ténacité, les performances à basse température sont meilleures que celles de l'acier inoxydable ferritique (mais inférieures à celles de l'acier duplex). |

| Module d'élasticité (Modulus) | 193 - 200 GPa | Semblable aux autres aciers inoxydables austénitiques. |

Avantages mécaniques

- Haute ductilité : convient aux processus de moulage par emboutissage (par exemple, pour la fabrication de casseroles et de poêles)

- Résistance à la fatigue : peut résister à plus de 106 les charges cycliques (adaptées aux charnières avec ouverture et fermeture fréquentes)

- Ténacité à basse température : pas de fissuration fragile, même à des températures d'azote liquide

Propriétés physiques

| Propriétés | Valeur numérique | Effet de l'application |

|---|---|---|

| Densité | 8,0 g/cm³ | environ 10% plus léger que l'acier au carbone, convient pour les composants structurels nécessitant une réduction de poids. |

| Coefficient de dilatation thermique | 17,2 μm/m-°C (20-100°C) | Un joint de dilatation est nécessaire. |

| Conductivité thermique | 16,2 W/m-K | L'apport de chaleur doit être contrôlé pendant le soudage pour éviter les déformations. |

| Résistivité | 0,73 μΩ-m | Peut être utilisé pour les pièces conductrices à faible courant. |

Avantages du noyau en acier inoxydable 304

Excellente résistance à la corrosion

Selon les données de l'Outokumpu Stainless Steel Corrosion Handbook :

- Taux de corrosion annuel <0,01mm au pH 4-9

- Résistant à la concentration 85% d'acide nitrique (à température ambiante)

- Pas de rouille visible pendant 10 ans en atmosphère industrielle à l'humidité 60%

Excellente aptitude à la transformation

- Emboutissage et formage : jusqu'à 2,2 LDR (Limit Depth Ratio)

- Compatibilité de soudage : Soudage TIG sans matériau d'apport pour des soudures à haute résistance

- Finition de la surface : Polissage électrolytique pour obtenir une finition miroir avec Ra ≤ 0,1μm.

Hygiène et esthétique

- Finition de la surface : Le taux d'adhésion des bactéries est inférieur de 90% à celui de la surface rugueuse.

- Nettoyage pratique : peuvent être nettoyés avec des acides forts et des alcalis (par exemple, désinfectant à base d'hypochlorite de sodium)

Résumé

Grâce à sa résistance équilibrée à la corrosion, à sa facilité de traitement et à son coût contrôlable, l'acier inoxydable 304 domine le secteur de la quincaillerie industrielle. Comme les exigences de l'industrie manufacturière en matière de longévité des matériaux et de protection de l'environnement augmentent, l'acier inoxydable 304 continuera à jouer un rôle clé dans les domaines du transport ferroviaire, de l'équipement pour les nouvelles énergies et des soins médicaux intelligents.

FAQ

Q : L'acier inoxydable 304 peut-il être utilisé en milieu marin ?

R : L'exposition à long terme à l'eau de mer n'est pas recommandée. Dans un environnement peu salin, il est nécessaire d'utiliser un revêtement de surface.

Q : Quelle est la différence entre l'acier inoxydable 304 et 201 ?

R : 201 avec du manganèse pour remplacer une partie du nickel, la résistance à la corrosion est moins bonne, le coût est inférieur d'environ 40%.

Q:Comment juger de la qualité de l'acier inoxydable 304 ?

R : La méthode professionnelle consiste à tester la teneur en nickel à l'aide d'un spectromètre. Test simple : déposez une solution de sulfate de cuivre sur la surface, si elle devient rouge, il s'agit d'un faux 304.

Q:L'acier inoxydable 304 rouille-t-il ?

R : La corrosion par piqûres peut se produire en présence d'ions chlorure ou de dommages mécaniques non traités à temps.