HTAN è uno dei principali produttori di cerniere, maniglie e chiusure industriali in Cina.

-

+86 13720060320

-

julius@haitangs.com

Industrial Cabinet Door Not Closing? Concealed Hinge Fix Guide

Industrial concealed hinges are essential for secure, space-saving cabinet doors in industrial environments, offering hidden installation, 3D adjustment, and long-lasting durability.

When electrical cabinet doors, equipment enclosures, or network cabinets fail to close properly, it can pose safety risks, compromise sealing integrity, and even reduce protection ratings (e.g., IP54, IP65).

Yet even with modern concealed hinges installed, cabinet doors may still misalign, spring open, or fail to lock securely. The good news is that such issues usually have clear causes and practical solutions.

This article outlines the most common problems and explains how to adjust or repair industrial concealed hinges to restore stable door closure.

What Are Industrial Concealed Hinges and Why Use Them?

Definition:

Industrial concealed hinges (also known as European concealed hinges) consist of two main components:

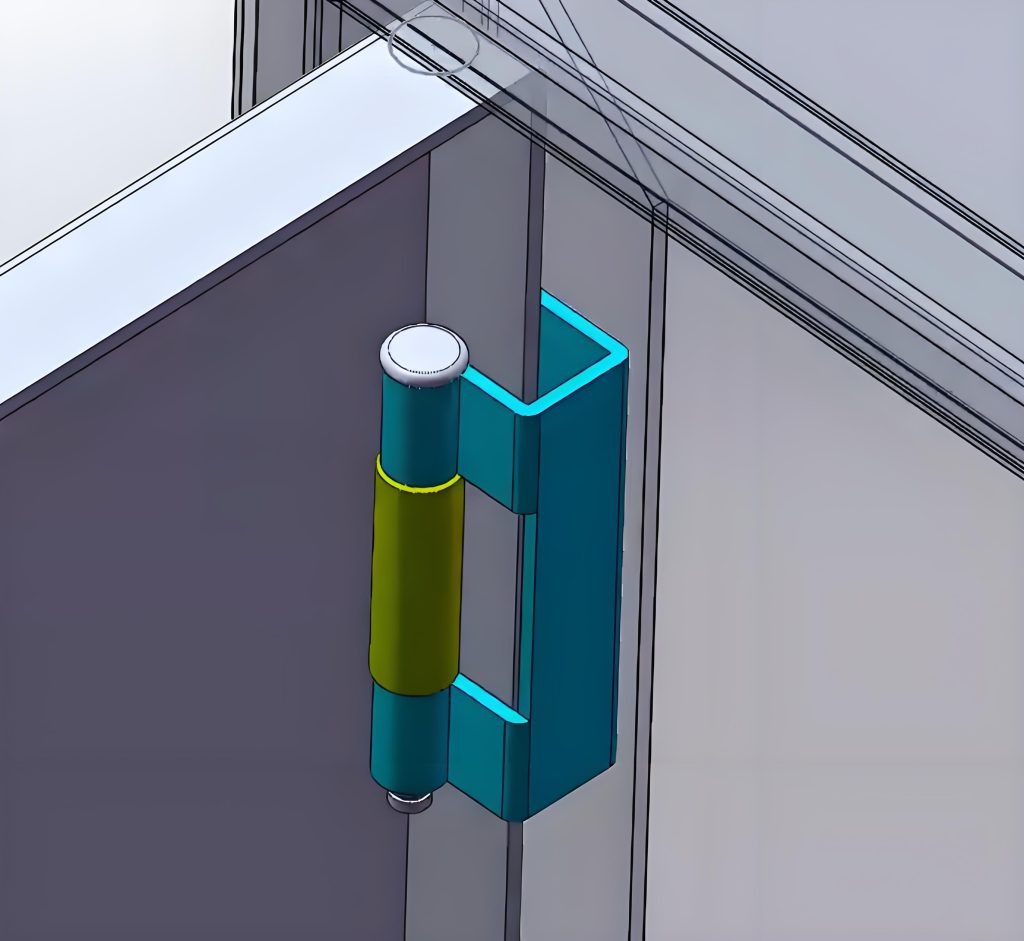

Structural Diagram of Industrial Concealed Hinge

- Hinge Cup – embedded within the cabinet door.

- Hinge Bracket – fixed to the cabinet body.

When the door closes, the hinge is completely hidden within the door or frame, leaving no exposed parts. This design not only enhances visual cleanliness but also prevents external tampering.

Applicazioni:

Application of Industrial Concealed Hinges on Various Cabinet Doors

- Electrical cabinets

- Industrial control panels

- Server room enclosures

- Medical and laboratory equipment cabinets

Key Benefits:

- Space-saving (no external protrusion)

- 3D adjustment capability: up/down, left/right, front/back

- Improved sealing and protection

Common Reasons for Industrial Cabinet Doors Not Closing Properly

Installation Deviation

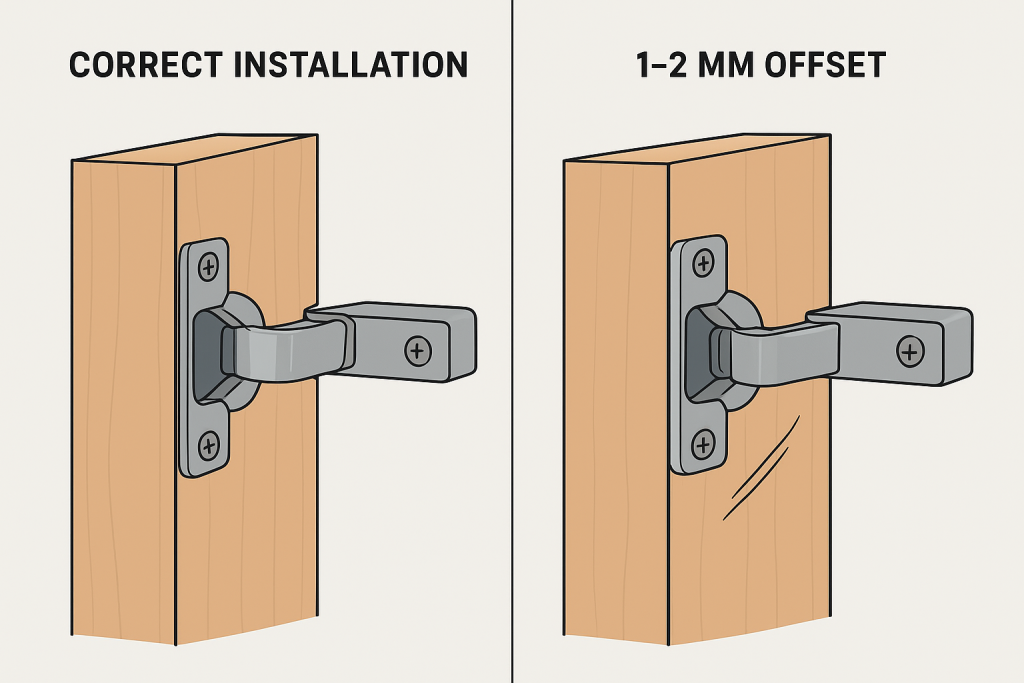

Concealed Hinge — Correct Installation vs. 1–2 mm Misalignment

- Misaligned hinge cup holes or bases.

- Even a 1–2 mm deviation may result in scraping or poor sealing.

- Critical for IP-rated cabinets where tight gaps are required.

Loose or Missing Screws

- Frequent vibration or stress → screws loosen.

- Missing screws reduce load-bearing capacity.

- Soluzione: Regularly check and tighten all screws.

Improper Adjustment

Industrial concealed hinges allow 3D adjustment:

- Vertical: Aligns door height.

- Horizontal: Adjusts gaps to prevent scraping.

- Front-back: Ensures gasket compression for IP54/IP65 sealing.

Substandard or Damaged Hinges

- Common failures: spring fatigue, arm deformation, latch breakage.

- Service Life Data:

- Low-quality hinges: fail within 1–3 years.

- High-grade stainless steel hinges: last 10–20 years.

- Soluzione: Replace with 304/316 stainless steel or heavy-duty models.

Cabinet Door or Cabinet Body Deformation

- Causes: welding stress, temperature variation, vibration.

- Minor Warping: adjustable with hinges.

- Severe Warping: requires door or frame replacement.

Insufficient Hinge Quantity

Rule of Thumb:

- Add 1 hinge for every 700–800 mm increase in door height.

- Doors >900 mm wide → require additional support.

Examples:

- Door height ≤1,200 mm → 2 hinges

- Door height 1,500–1,800 mm → 3 hinges

- Door height ≥2,000 mm → 4 hinges

Other Potential Issues

- Dust, grease, or shavings blocking hinges.

- Rust or poor lubrication.

- Internal equipment/cables obstructing closure.

- Welding or drilling errors during fabrication.

How to Adjust and Repair Industrial Concealed Hinges

Comprehensive Inspection

- Check hinge alignment.

- Tighten screws.

- Confirm hinge model matches door thickness.

Three-Dimensional Adjustment

- Up/Down: Loosen base screws, fine-tune height.

- Left/Right: Rotate adjustment screws for proper door gap.

- Front/Back: Adjust seal pressure for IP compliance.

Repair or Reinforce Screw Holes

- Use larger screws, metal rivets, or screw sleeves.

- (Wood cabinet fixes like toothpicks/glue are not suitable for industrial use).

Replace with High-Quality Hinges

- 304/316 stainless steel → corrosion resistance.

- Galvanized/powder-coated steel → cost-effective.

- Soft-close hinges → reduce impact, extend lifespan.

Correct Deformed Components

- Minor warping: hinge adjustment.

- Severe warping: replace panels or recalibrate frame.

How to Prevent Industrial Cabinet Door Issues

- Hinge Selection: Match hinge load capacity to door weight/dimensions.

- Installation Precision: Keep drilling/welding alignment tolerance within ±1 mm.

- Regular Maintenance:

- Tighten screws every 3–6 months.

- Clean and lubricate hinges at least quarterly.

- Corrosion Protection: Use stainless steel outdoors/humid areas.

- Hinge Quantity: Heavy doors ≥1.5 m height → at least 3 hinges.

FAQ

Q: Why do my electrical cabinet doors never align properly?

A: Likely hinge misalignment (1–2 mm offset) or cabinet deformation. Try 3D adjustment first, then check for warping.

Q: How long do industrial concealed hinges last?

A:

- Standard hinges: 5–10 years.

- High-grade hinges: 10–20 years.

- Outdoor or high-frequency use: check every 12 months.

Q: My cabinet door is too heavy to close securely. What should I do?

A:

- Verify hinge quantity:

- ≤1.2 m door: 2 hinges

- 1.5 m door: 3 hinges

- ≥2 m door: 4 hinges

- Consider heavy-duty models.

Q: Should I hire a professional for repairs?

A:

- Basic maintenance (tightening/adjustment) → in-house staff.

- Severe deformation/welding errors → professional repair.

Conclusione

Industrial cabinet doors failing to close properly are usually caused by installation errors, loose screws, inadequate hinge adjustment, or hinge damage.

Most can be fixed by inspection + 3D adjustment. For deformation or hinge failure, replace with high-quality industrial concealed hinges to ensure long-term stability and sealing performance.