HTAN è uno dei principali produttori di cerniere, maniglie e chiusure industriali in Cina.

-

+86 13720060320

-

julius@haitangs.com

How to Choose Concealed Hinges for Industrial Cabinets: A Complete Guide

A neglected hinge can doom an expensive server cabinet. If the hinge sags, the door warps, sealing fails and safety drops. In harsh plants, every detail counts – a hinge is the joint between door and frame, critical far beyond its size. Concealed hinges sit entirely inside the cabinet. They hide all hardware when the door is closed, delivering a smooth, unbroken exterior. In modern industry this hidden hinge is core to sleek design, plus high security and robust protection. Yet the market is flooded with options: dozens of materials, ratings and features. How do engineers or buyers make a sure choice? This guide lays out a systematic, seven-point selection method. We will cover each key factor in detail, with real-case examples, so you can pick the exact concealed hinge to secure your industrial cabinet or chassis.

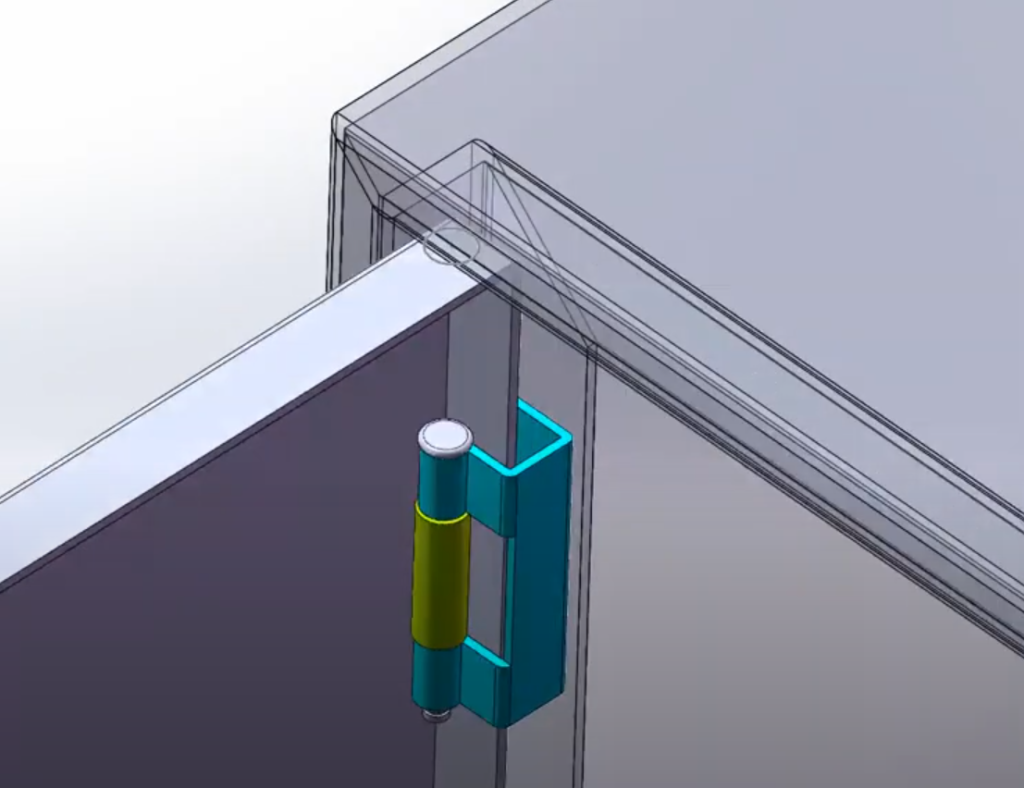

Concealed hinge hidden inside an industrial cabinet

What Is a Concealed Hinge and Why Is It Favored in Industry?

Before choosing a hinge, understand what it is and what it does. A concealed hinge is simply one that disappears from view when the cabinet door closes. Its mechanism – plates, pins and links – is mounted inside the door and frame. This invisible design contrasts sharply with old-fashioned exposed hinges (butt or strap hinges) whose pins and leaves always show. A concealed hinge keeps external surfaces flat and clean. The engineering behind it often uses multiple linkage points or arms. These multi-pivot mechanisms enable very smooth, controlled motion even for heavy doors.

Definition:

A concealed hinge is fully hidden by the door in its closed position. The pivot mechanism is buried inside the cabinet wall. When you open the door, arms or links extend in a precise path, then retract again on closing. Many designs feature two or more pivot points. This allows the door to swing smoothly without scraping any seals or frames, even up to 180°. High-security enclosures often use heavy-duty concealed hinges with weld-on or screw-on mounts – every part is engineered to bear weight and motion in tough conditions. In short, a concealed hinge is not just a pivot; it’s a multi-part system built for strength and smooth action.

The hidden design delivers several powerful advantages in industrial settings:

Sleek Appearance:

With no hardware showing, cabinets look modern and seamless. Full-overlay concealed hinges cover the frame fully, leaving little gap between doors. Two cabinets side-by-side can sit flush. The result is a clean, monolithic exterior that fits high-tech environments. Modern control panels and racks often use concealed hinges for this polished look.

High Security and Anti-Tampering:

A hinge hidden inside means no external screws or exposed pins to pry. Intruders cannot easily remove or force the door by attacking the hinge from outside. Engineers cite concealed hinges as ideal for security cabinets and outdoor telecom boxes, since “they prevent tampering from the outside”. In other words, any attempt to force the door must break the outer shell first, not just pop the hinge off.

Efficienza dello spazio:

Hidden hinges let doors sit closer to each other and to walls. A door that overlays the full frame can meet an adjacent unit edge-to-edge with zero gap. In data centers or control rooms where racks are tight, this saves precious space and makes the installation compact. It also means fewer protruding parts to bump into.

Improved Sealing and Protection:

Concealed hinges integrate well with seals and gaskets. Because they often allow the door to rise or move out slightly before swinging open, they avoid scrubbing against frame seals. This protects any rubber gasket from wear. Also, the hinge itself can be designed as part of the enclosure’s IP seal. Properly aligned concealed hinges help the cabinet meet dust/water protection ratings. (In fact, technicians stress that correct hinge alignment is critical to maintain any gasket’s seal and IP rating.)

Each of these points is vital in industry. A hidden hinge boosts aesthetics, seals better, and wards off intruders. Its complexity inside is the price for those benefits. With this foundation in mind, the next sections drill into the seven key factors every engineer or buyer must consider when selecting a concealed hinge.

Seven Core Factors in Hinge Selection

Now we move to the heart of selection: a step-by-step look at seven critical factors. Treat this as a check-list that builds from basic to advanced needs. Skip any factor at your own risk – each plays a role in success.

Load Capacity – The Foundation of Safety

First and foremost, a hinge must be able to carry the door weight reliably. A hinge failure is a major safety hazard: imagine a 200-pound steel door dropping on equipment or people. Start with weight calculations. Calculate door weight as thickness × width × height × material density. For example, if your door is 2 m × 0.5 m × 0.01 m made of mild steel (density ~7850 kg/m³), its weight is 2×0.5×0.01×7850 ≈ 78.5 kg. Tip: Always use metric units consistently to avoid errors.

Next, account for lever arm effect. A wider door exerts more torque on its hinges even if weight is equal. A double-door or very wide panel can sag faster than a narrow one of the same weight. So, always check the hinge spec not just for total weight but for indicated door width or offset. Manufacturers often list something like “holds 80 kg per pair (for 1.2 m door)” which already factors in size.

Now interpret manufacturer ratings correctly. If a hinge pair is rated “100 kg (2 hinges)”, it means those two can carry 100 kg total at the tested door dimensions. If your door is heavier or larger, step up a model. Best practice: Choose a hinge rated at least 20–30% above your calculated need. This safety margin covers dynamic loads (bouncing open/close, minor impacts) and long-term wear. For example, if your calculation shows 50 kg, pick a hinge (or hinge pair) rated for ~65 kg. Over-engineering a bit here prevents future surprises.

Material and Surface Finish – Durability Guarantees

With weight sorted, pick a strong, resilient material. Hinges come in several metals and alloys:

Acciaio inox (e.g. SS304 o SS316):

Extremely corrosion-resistant and strong. Ideal for harsh environments – outdoor, coastal (salt spray), chemical processing, food and medical gear, or anywhere moisture is a worry. SS316 has even better rust resistance than 304. Use stainless hinges when longevity against corrosion is vital.

Zinc Alloy:

Often used by die-casting for moderately-priced hinges. Zinc alloy offers good strength and allows intricate shapes. Many indoor equipment and electronic cabinet hinges use zinc alloy because it’s cost-effective and still rust-resistant after plating. It also takes paint and plating well.

Steel (carbon steel, e.g. Q235):

Very high tensile strength, good for heavy loads and impacts. Heavier and cost-effective. Common in large machinery and heavy-duty cabinets (e.g. switchgear, large generator enclosures). Because plain steel can rust, these hinges are usually zinc-plated, chromed, or powder-coated for protection.

Aluminum:

Lightweight and good corrosion resistance (especially anodized). Used when weight reduction is important (e.g. aircraft, rail transit equipment) and loads are moderate. Not as strong as steel, but its low density can matter for large doors.

Don’t overlook surface finish. Even the right material can fail if not treated. Typical finishes include:

Zinc Plating or Chrome Plating:

A thin electroplated coat for rust protection on steel or zinc parts. Suitable for indoor or mild environments.

Powder Coating:

A baked-on paint (often epoxy or polyester) that gives both color and corrosion resistance. Common on steel hinges in painted cabinets.

Electrophoretic (E-coat):

An even, thin paint finish often used on automotive and high-end electronics. It seals small nooks uniformly and is very corrosion-resistant.

In short, match the hinge material and coating to your environment. The hinge should survive outdoors (sun, rain, salt) or indoors (humidity, chemicals) without rust. Quality suppliers will list the material (e.g. “SS304 stainless”) and any plating or coating. Remember: a stainless hinge needs no plating (and even shouldn’t have one, to maintain non-corroding properties).

Opening Angle – Meeting Operational Needs

Consider how far the door must open. Most hinges offer a fixed maximum angle:

90°–120° Hinges:

These are common for cabinets in tight spaces. They open enough for most access tasks but also stop the door before it swings fully back, which helps prevent collision with walls or adjacent racks.

180° (or Greater) Hinges:

These allow the door to swing fully back or lie flat against the cabinet side. Use these for situations where full clearance is needed – for example, mounting heavy equipment inside the cabinet or servicing all components easily. A 180° hinge lets the door get completely out of the way.

Choose the angle by imagining the real workspace. If a cabinet door opens into a busy aisle, maybe 120° is enough. If it’s a standalone control panel that needs full access, pick a 180° or multi-link hinge. Also check if the hinge supports over 180° swings (some special hinges allow >180° for even more clearance). The hinge spec sheet should state the angle. Double-check that this meets your installation layout.

No citation needed here; this is straightforward design reasoning.

Additional Features – Upgrading Convenience and Safety

Modern hinges often add features beyond mere pivoting. These features improve ergonomics and longevity:

Damping (Soft-Close) or Buffer:

A built-in damper or hydraulic piston slows the door at the end of closing. This prevents slamming. It reduces noise and wear – critical in a control room or data center where a slammed door could jar equipment or disturb noise-sensitive operations. If your cabinet holds delicate electronics or if doors are opened often, consider a soft-close hinge or an external damper.

Hold-Open or Self-Locking:

Some hinges can lock at certain angles or automatically hold the door open at, say, 90°. This frees hands for work: an engineer can open a heavy panel and not have to prop it up. It also improves safety (the door won’t swing unexpectedly). This is often a mechanical detent or spring inside the hinge.

Quick-Release / Tool-Free Removal:

Hinges that allow the door leaf to unclip or the pin to pop out easily can simplify assembly, shipment, or maintenance. For example, a quick-release pin lets you lift the door out of the frame when needed without unscrewing anything. This is useful on large, heavy doors for transport or for quickly swapping panels in the field.

Three-Dimensional (3D) Adjustability:

This is a big one for heavy industrial doors. A 3D adjustable hinge means once installed, you can fine-tune the door’s position along three axes (up/down, left/right, and in/out) with simple screws. This precision is key for heavy steel doors with seals: even a millimeter off can cause a seal to bulge. With 3D adjustment, installers align the door perfectly so it mates cleanly with the frame. Industry experts emphasize that this adjustability is essential to ensure a perfect fit on heavy precision doors. Always look for this if alignment is critical.

In practice, match these features to your needs. A consumer hinge might not have any of these. But for an industrial cabinet, extra features can justify their cost through safer, easier operation and longer life. For instance, an adjustable hinge ensures you won’t have to unbolt the door later to shim it into place. A damped hinge prevents metal-on-metal banging. Think of them as professional-grade convenience that prevents problems.

Installation and Door Overlay – Structural Compatibility

The hinge must match how your door is built and how it mounts. First, consider the door overlay style – this is how the door sits on the frame:

Full Overlay:

The door completely covers the cabinet side panel (no frame is visible when closed). This is popular in high-tech equipment for a sleek look. Full-overlay hinges hold the door entirely off the frame edges.

Half Overlay (Partial Overlay):

Two doors share a central partition. Each door covers half the partition, overlapping each other when closed. Common in designs where a partition wall is doubled up. Hinge manufacturers specify if a hinge is half-overlay.

Inset Door:

The door sits entirely inside the frame and is flush with the frame face. This requires an inset hinge that can swing the door out and away as it opens so it clears the frame. It gives a “window-like” look where the face is flat.

Choose the hinge style that matches your door type exactly. A full-overlay hinge won’t mount correctly on an inset door, and vice versa. Most industrial hinges come as pairs: the door-leaf and the frame-leaf (or cup and plate). Make sure to get the correct type (the spec sheet will usually say “for full-overlay doors of X mm thickness,” etc).

Next, decide the fixing method. Hinges attach to the door and frame in different ways:

Screw-On (Bolt-On):

The hinge leaves have holes for screws or bolts. This is the most common method for metal cabinets and enclosures. It’s easy to install or replace. You screw one leaf into the door, and one leaf into the frame.

Weld-On:

The hinge leaves have flat areas or lugs intended to be welded. Weld-on concealed hinges exist for very heavy-duty or permanent installations. A welded hinge forms a weld line as strong as the base metal itself. Use this for large security doors or containers where you don’t want removable fasteners.

Rivet or Adhesive:

Less common for heavy use. Rivets might be used in mass-produced light enclosures. Adhesives are rare for metal, maybe for plastics.

Essentra Components highlights that some industrial hinges are available in dual versions: they have screw holes and a weldable pad. For heavy cabinets, weld-on provides maximum strength, but at the cost of permanence. Choose based on whether you need future adjustability (screws) or ultimate sturdiness (weld). In any case, ensure the hinge’s mounting design aligns with your door thickness and frame thickness. Many hinges list recommended screw sizes and hole dimensions.

Environmental Requirements – Don’t Forget Context

Think through where the cabinet will live and what conditions it sees. The hinge must endure whatever the environment throws at it:

IP Rating (Sealing):

If the cabinet is rated for dust/water ingress (IP65, IP67, etc.), the hinge must not compromise the seal. Some concealed hinges are specifically built to compress on closing or have minimal gaps. In tight ratings, the hinge pocket area often has extra gaskets or covers. Remember that even a slight misalignment of the hinge can break a gasket seal – so precise mounting is key. If the hinged door has a gasket, pick a hinge that supports that thickness and closes flush.

Corrosion and Weather:

Outdoor cabinets face rain, UV, and temperature swings. Inside factories you may have chemical spray or high humidity. Choose corrosion-resistant materials as discussed, and consider extra coating if corrosive spray is expected (like in food processing, use stainless).

Vibration and Shock:

Mobile or heavy-equipment installations (vehicles, ships, generators) shake a lot. A hinge here must be rugged and possibly include locking pins. Welding often helps. Some hinges are rated for vibration; otherwise, expect to secure the door with additional latches beyond the hinge.

Temperature Extremes:

Very hot or cold environments can affect hinge lubrication and steel grades. If using dampers, ensure they function at the expected temperature range (some hydraulic dampers stiffen in cold). Also make sure any plastic or rubber parts in the hinge won’t become brittle in the cold or soften in heat.

EMC and Grounding:

In electrical enclosures, the door often needs to stay electrically bonded to the cabinet for grounding/EMI reasons. Some hinges double as grounding links, replacing the need for separate ground straps. If EMI or grounding is a concern, look for earth-bonding hinges or hinges with conductive pin assemblies. Otherwise, ensure you add your own grounding strap.

Each special requirement may eliminate some hinges. For example, even if a plastic hinge is cheap, it won’t fly in a dusty/wet or high-security outdoor telecom box. List all environmental factors early and confirm hinge specs cover them (look for IP numbers, salt spray hours, etc., in datasheets if available).

Brand, Certifications and Total Cost – The Long View

Finally, weigh quality and cost. With hinges, cutting corners can be costly down the line. A well-known industrial hinge brand typically means better quality control and testing (they’ve probably done long life-cycle tests). Look for certifications on the product: ISO 9001 (quality management), RoHS(lead-free, if in Europe), UL listings (for electrical enclosures), etc. These indicate the manufacturer meets standards.

Now, cost analysis. A high-spec hinge (stainless, precision, 3D-adjust, etc.) has a higher unit price than a simple off-the-shelf one. But ask: what is the lifecycle cost? A cheaper hinge might corrode or break, causing downtime, repairs, or even safety incidents. Those costs easily exceed the hinge price. Recall DOHO Electric’s advice: choosing the wrong hinge can “result in decreased performance, increased wear and tear, and even security vulnerabilities”. Think of it as buying insurance for your enclosure. A premium concealed hinge can save money by preventing accidents or service calls later.

Practical tip: When evaluating suppliers, ask for technical support or 3D models early. A conversation with the hinge maker’s engineer can clarify hidden requirements. Also check if the supplier offers guarantees or has experience in your industry sector. Sometimes regional standards or approvals matter (e.g. hinges already approved for certain telecom or military cabinets).

In summary, don’t just compare two prices. Compare two packages: performance and service. The “best” hinge is the one that meets all your technical needs and still makes sense economically over the equipment’s lifetime.

Case Studies: Applying the Rules

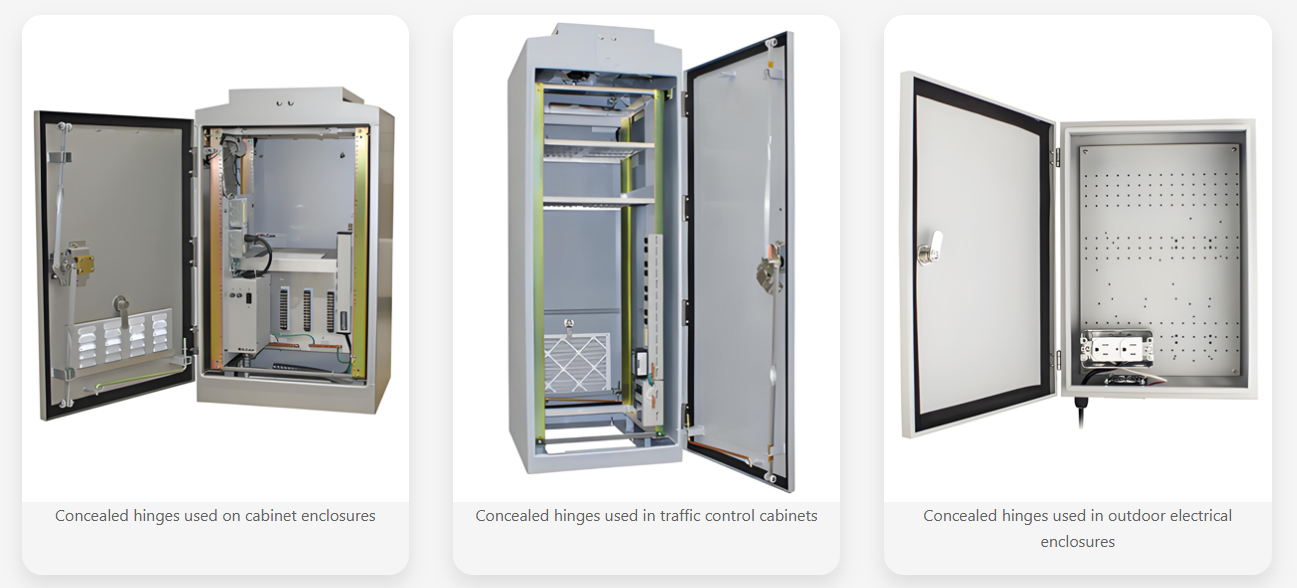

Industrial applications of concealed hinges (telecom cabinet example)

Theory matters, but let’s see these principles in action. Below are three typical scenarios:

Case 1: Outdoor Telecom Cabinet.

The cabinet sits outside, protecting communication electronics. Requirements: High weather resistance, vandal/damage resistance, wide open access for maintenance. It needs dust/water sealing (say IP54+). The hinges must not be removable from outside.

Solution: Use stainless-steel concealed hinges with heavy-gauge plates. Pick a 180° hinge to swing doors fully open. Ensure the hinges have high corrosion certification (316 stainless). Install a hinge with no exposed fasteners (possibly weld-on). The concealed hinge prevents theft/tampering – it’s ideal here. Add a heavy-duty gasket around the door.

Case 2: Indoor Data Center Rack.

The cabinet is a metal server rack inside a data hall. Requirements: Very heavy door, frequent opening/closing, need precise alignment to maintain airflow seals. Space is also tight between racks.

Solution: Choose a hinge with extremely high weight capacity. A multi-link concealed hinge can handle 50+ kg doors and distribute load over several pivots. It should offer 180° opening for unobstructed access to equipment. Crucially, select a 3D adjustable model so that installers can align the heavy door perfectly flush – this avoids air leakage and friction. A steel hinge (possibly zinc-coated) suits indoor environment. Self-release pin or quick-release helps when many servers are swapped.

Case 3: Precision Equipment Control Cabinet.

Inside a factory, this cabinet contains sensitive controls. Requirements: Smooth, quiet closing, perfect seal, prevent dust ingress. The door is moderate weight, ambient indoor conditions.

Solution: A concealed hinge with built-in damping or soft-close will ensure the door always closes gently. Combine this with a good rubber gasket around the door frame. The hinge material can be zinc alloy or stainless steel based on cost vs cleanliness. Full overlay style maintains a flush exterior. No specific need for high open angle (maybe 120° is enough). If electrostatic discharge is a concern, ensure the hinge is metal (for grounding). In this case, the hinge mainly aids in quiet, reliable access and sealing the cabinet – it’s the silent guardian of the sensitive electronics.

These examples illustrate the full process: list demands, then match hinge attributes. Notice how factors like material, strength, and functions are chosen to fit each use case precisely.

Ultimate Checklist and Common Pitfalls

To wrap up, here’s a quick self-check before you finalize a hinge selection:

- Have I calculated the door weight and torque? Don’t forget width.

- Does the hinge’s capacity exceed my needs by 20–30%?

- Is the chosen material and finish suited to corrosion and wear conditions?

- Does the opening angle meet the access requirements?

- Do I need any extra features (soft-close, hold-open, quick-release)?

- Does the hinge match the door style (inset, half/full overlay) and mounting method?

- Have I accounted for vibration, temperature, IP rating, grounding, etc.?

Also watch out for these common mistakes:

Mistake 1: Choosing by Price Alone.

A cheaper hinge can mean hidden costs later. Always balance price with quality, support, and total cost of ownership.

Mistake 2: Ignoring Door Width (Lever Arm).

Focusing only on weight can fail you. A light but very wide door can still sag. Always factor in the size of the door.

Mistake 3: One-Size-Fits-All.

Using the same hinge model everywhere ignores differences in conditions. For example, don’t use mild-steel hinges outdoors just because they worked indoors.

Mistake 4: Skipping Adjustment.

If you use an adjustable hinge, make sure to do the final tuning. A 3D-adjustable hinge that isn’t tweaked is a wasted feature. Misalignment can ruin the seal or wear the hinge prematurely.

In short, double-check each item. A little extra diligence now prevents failures on the factory floor.

Conclusione

Selecting a concealed hinge for an industrial cabinet is a comprehensive decision. It influences the cabinet’s appearance, its security, and even the safety of your operation. The right hinge is not just a part; it’s a key element of the entire system’s reliability. Professional eyes should examine every “joint” in your design – from how much load it bears to how it meets tough environmental demands.

Think of investing in the perfect hinge as buying peace of mind. By methodically working through these factors, you ensure your cabinet will function smoothly for years. Don’t just stop at the datasheet – talk to hinge experts and test-fit if possible. In doing so, you won’t just purchase a hinge; you’ll secure long-term safety and performance.

Make it a habit: scrutinize every joint in your industrial design as carefully as its electronics. That attention to detail is what separates ordinary equipment from truly exceptional, reliable gear.