A HTAN é um dos principais fabricantes de dobradiças, pegas e fechos industriais na China.

I. Funções essenciais e conhecimentos básicos

Dobradiças de torque: Uma breve panorâmica

Uma dobradiça de binário é um componente mecânico concebido para conseguir "pairar livremente" através do seu mecanismo de resistência interno. Ao contrário das dobradiças normais, permite que as peças ligadas (como tampas, ecrãs, painéis de portas, etc.) permaneçam estáveis em qualquer ângulo sem necessidade de dispositivos de suporte adicionais. Esta funcionalidade única aumenta a conveniência operacional e a segurança do equipamento, ao mesmo tempo que prolonga a sua vida útil.

Aplicações típicas

- Pivôs para ecrãs de computadores portáteis(Está disponível um guia de aplicação para fusos de ecrãs de computadores portáteis:Dobradiça de torque para computadores portáteis Principais exigências e guia abrangente)

- Portas de automóveis

- Braços de ajuste de equipamentos médicos

- Portas de armários para móveis

II. Tipos comuns e cenários de aplicação

| Tipo | Caraterísticas e utilizações típicas | Preocupações com as compras |

|---|---|---|

| Tipo padrão | Económicos e práticos, adequados para requisitos comuns de suporte de carga (por exemplo, portas de armários de móveis) | Económica; prestar atenção à marcação da vida útil de abertura e fecho |

| Ajustável | Resistência ajustável manualmente para se adaptar a diferentes equipamentos de pesos | Confirmar a gama de regulação (por exemplo, 0,5-20 Nm) |

| Oculto | Instalação incorporada, aspeto simples (normalmente utilizado em produtos electrónicos topo de gama) | Verificar a dimensão da instalação e os requisitos de tratamento da superfície |

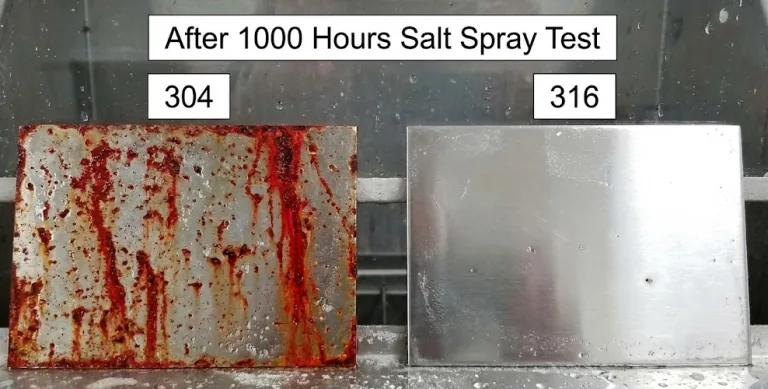

| Resistente à corrosão | Material resistente à ferrugem (por exemplo, aço inoxidável), adequado para ambientes húmidos/químicos | Exigir relatórios de ensaios de resistência à corrosão |

| Serviço pesado | Capacidade de carga igual ou superior a 200 kg, utilizada para máquinas de construção/equipamento pesado | Relatório de ensaio de carga necessário |

| Resistente ao fogo | Material resistente a altas temperaturas, utilizado para portas corta-fogo de edifícios/equipamento industrial | Verificar a certificação de incêndio (por exemplo, certificação UL) |

III. Indicadores-chave da seleção de compras

Correspondência de binário

- Fórmula de cálculo: Valor do binário ≈ Peso do equipamento (kg) × Comprimento do braço de força (m) × Fator de segurança (1,2-2,0)

- Exemplo: Para um ecrã de 10 kg com um braço de força de 0,2 m, o binário necessário para a dobradiça deve situar-se entre 2,4 e 4 Nm.

Pontos de verificação da qualidade

- Durabilidade: Vida útil de abertura e fecho ≥ 50.000 vezes (os modelos topo de gama têm de ser ≥ 100.000 vezes)

- Adaptabilidade ambiental: A faixa de temperatura operacional (-30 ℃ ~ 80 ℃) basicamente atende à maioria dos cenários

- Material: Liga de alumínio (leve) / Aço inoxidável (resistência à corrosão) / Plásticos de engenharia (isolamento)

Compatibilidade de instalação

- Diâmetro do eixo: Os tamanhos mais comuns vão de 3 a 20 mm

- Distância do furo de montagem: Confirmar o método de fixação (parafusos/soldadura)

- Design oculto: Comunicar antecipadamente a dimensão do espaço interior do equipamento

IV. Avaliação de fornecedores e controlo de custos

Critérios de seleção de fornecedores

- Qualificação: Sistema de gestão da qualidade ISO 9001

- Capacidade de ensaio: São necessários relatórios de ensaios de binário e resultados de ensaios de pulverização salina de terceiros

- Apoio ao serviço: Disponibilidade de modelos 3D, orientação de instalação e serviços personalizados(HTAN oferece modelos 3D gratuitos)

Estratégias de otimização de custos

- Compra a granel: Os descontos de 5%-10% estão normalmente disponíveis para encomendas superiores a 500 peças

- Soluções alternativas: Preferir os modelos standard aos modelos personalizados, desde que os requisitos de desempenho sejam cumpridos

- Acordos a longo prazo: Fixar os preços através da assinatura de acordos-quadro com fornecedores de alta qualidade

Prevenção de riscos

- Exigir que os fornecedores forneçam, pelo menos, uma garantia de 1 ano

- Rever casos de cooperação anteriores, especialmente os do mesmo sector

V. Manutenção e gestão pós-venda

Manutenção de rotina

- Limpar a superfície da dobradiça de 6 em 6 meses

- Lubrificar uma vez por ano (utilizar massa de silicone ou lubrificantes especializados)

Tratamento de problemas comuns

- Afrouxamento/estrangulamento: Verificar o aperto dos parafusos e substituir imediatamente as peças gastas

- Perda de resistência: Pode ser necessário substituir a placa de fricção interna

Gestão de peças sobresselentes

- Recomenda-se a reserva de 5%-10% das peças de desgaste (por exemplo, placas de fricção, parafusos de ajuste)

VI. Referência de casos de aplicação no sector

| Indústria | Cena típica | Tipo recomendado |

|---|---|---|

| Eletrónica de consumo | Pivô do ecrã do computador portátil | Oculto, ajustável |

| Equipamento médico | Braço de ajuste do ângulo da luz cirúrgica | Aço inoxidável de qualidade médica, tipo mudo |

| Fabrico industrial | Junta giratória do braço robótico | Ajuste multi-direcional resistente |

| Fabrico de automóveis | Dobradiça do ecrã/porta do automóvel | Resistente à temperatura (-40℃~120℃) |

| Mobiliário | Portas de armários topo de gama | Tipo de amortecimento silencioso, tipo oculto |

VII. Lista de decisões de compra

- Definir requisitos: Capacidade de carga, método de instalação, ambiente de utilização

- Recolher cotações e programas técnicos: De pelo menos 3 fornecedores

- Verificar amostras: Foco na estabilidade e durabilidade do binário

- Avaliar o tempo de resposta do fornecedor e as condições do serviço pós-venda

- Assinar um acordo de qualidade: Antes de efetuar compras em grande quantidade, assegurar critérios de aceitação claros

Conclusão

Este guia fornece aos compradores uma compreensão abrangente da lógica de seleção central para dobradiças de binário. Ao equilibrar o desempenho, o custo e o risco de fornecimento, pode selecionar soluções rentáveis para a sua organização. Recomenda-se vivamente que dê prioridade a fornecedores com experiência no sector e apoio técnico para garantir uma relação estável a longo prazo.

-768x768-1.png)