HTAN является одним из ведущих производителей промышленных петель, ручек и защелок в Китае.

-

+86 13720060320

-

julius@haitangs.com

Промышленные скрытые петли: Дизайн, долговечность и инновации

Concealed hinges seamlessly blend exceptional functionality with aesthetic design, as defined in the general concept of a петля. They provide a smooth, uninterrupted surface in industrial equipment, creating a cleaner, more modern appearance. Increasingly, manufacturers and cabinet makers recognize that using them simultaneously improves both product reliability and visual quality.

What Are Concealed Hinges in Industrial Applications?

Concealed hinges consist of a hinge cup mounted inside cabinet doors and a base fixed to the cabinet frame, remaining fully hidden when the door is closed. Typical industrial applications include:

Photos of Concealed Hinge Applications

- Electrical distribution cabinets and control panels

- Server room racks

- Шкафы для медицинского и лабораторного оборудования

All these applications demand clean surfaces and sealing performance. Industry experts emphasize that concealed hinges are crucial for “achieving safe, space-saving cabinet door designs.”

The Importance of Concealed Hinges in Industrial Environments

Streamlined and Safe Design

When closed, concealed hinges are fully hidden with no exposed components, offering a cleaner aesthetic while eliminating safety hazards from protruding parts.[industrial design aesthetics and safety]

Space Optimization

Their flush-mounted installation occupies no external space, significantly increasing internal cabinet utilization.

Durability and Low Maintenance

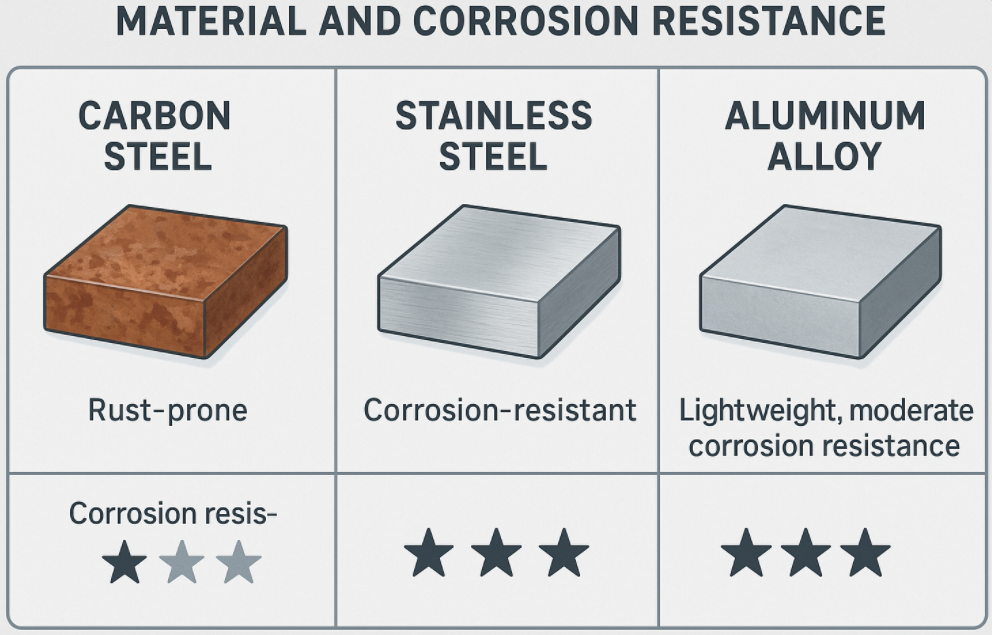

Concealed hinges are typically crafted from high-strength metals (carbon steel, stainless steel, aluminum alloy) with anti-corrosion treatment. Soft-close functionality reduces impact wear, further extending service life. These designs ensure longer durability and minimal maintenance requirements.[Arguments for the Corrosion Resistance of Stainless Steel]

Aesthetics and Brand Value

Concealed hinges create smooth, seamless surfaces that align with modern minimalist design, significantly elevating product quality and brand image. The cleaner, more sophisticated appearance of equipment makes this visual effect a key factor in differentiating industrial product brands.

Core Features and Engineering Advantages

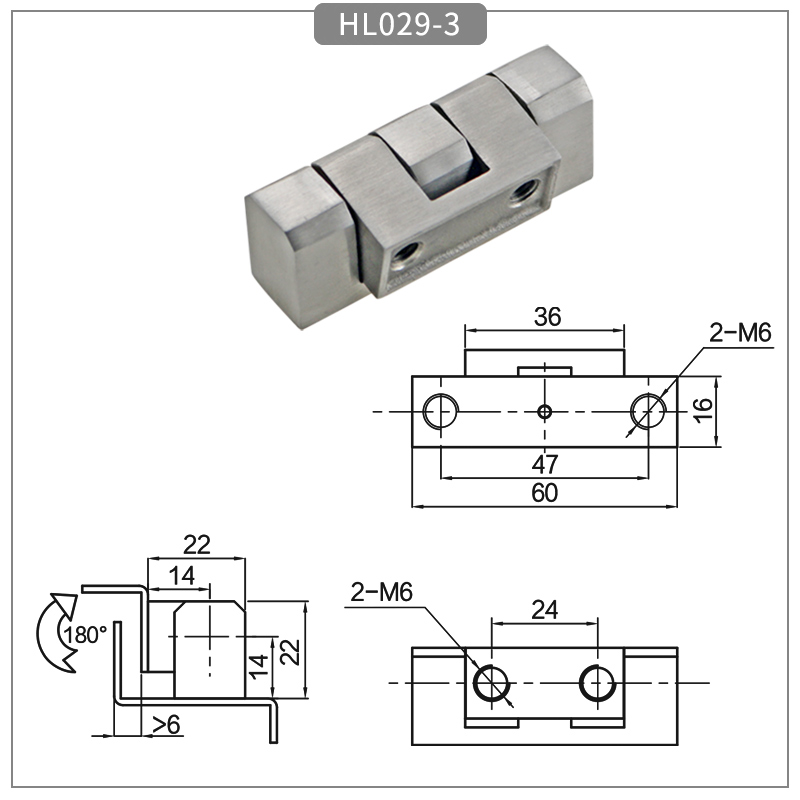

Industrial Concealed Hinge Model: HL029-3 Structural Diagram

Industrial concealed hinges feature the following key characteristics:

- Multi-axis Adjustability: Supports precise adjustments in vertical, horizontal, and front-to-back directions to ensure accurate door frame alignment.

- Высокая грузоподъемность: Reinforced design supports door panels weighing several dozen pounds (tens of kilograms).

- Устойчивость к коррозии: Premium models utilize 304/316 stainless steel or galvanized steel with anti-corrosion treatment, suitable for harsh environments.[Corrosion-Resistant Hinges guide]

Сравнение скрытой петли и традиционной петли

Сравнение скрытой петли и традиционной петли

| Сравнительное измерение | Скрытая петля | Traditional Exposed Hinge |

|---|---|---|

| Внешний вид | Concealed installation, seamless aesthetics | Exposed hinges, high visibility |

| Space Utilization | Built-in installation, space-saving | Requires door pivot clearance, occupies external space |

| Техническое обслуживание | Low: Durable and maintenance-free | High: Prone to dust accumulation, requires regular upkeep |

| Безопасность | Vandal-resistant: No exposed components | Low security: Visible parts vulnerable to damage |

| Стоимость | Slightly higher initial cost, lower long-term expenses | Low initial cost, high long-term maintenance expenses |

As evident, concealed hinges not only enhance aesthetics but also deliver comprehensive value in durability and safety.

Selecting Suitable Concealed Hinges for Industrial Applications

When selecting hinges, first evaluate door panel dimensions and weight to ensure adequate load capacity. Then choose materials based on the usage environment (indoor/outdoor/corrosive). For high-frequency use scenarios, prioritize models with enhanced durability. For doors involving safety operations, consider slow-close or quick-release designs to improve reliability.

Procurement Insights: What Industrial Buyers Should Focus On

- Supplier Qualifications: Prioritize suppliers with certifications like ISO9001, RoHS/REACH to ensure quality and compliance.

- Quality Control: Request torque life and salt spray test reports to verify durability and corrosion resistance; suppliers’ traceability systems facilitate quality oversight.

- Total Cost Perspective: Premium concealed hinges offer 10–20 year lifespans, delivering lower total cost of ownership than conventional solutions and higher long-term ROI.

Industry Trends: The Future of Concealed Hinges

Concealed hinges are evolving toward smart and sustainable designs: Future hinges will integrate with IoT systems for intelligent monitoring and automated control; lightweight alloys and sustainable materials will reduce weight while enhancing durability. Ultimately, they will deeply integrate with smart cabinets and Industry 4.0, unlocking greater possibilities for industrial automation equipment.[Industry 4.0]

Case Studies: Successful Applications of Concealed Hinges

Case Studies: Successful Applications of Concealed Hinges

Case : Automated Inspection Equipment

Switching to concealed hinges enabled smoother door operation and significantly improved maintenance efficiency.

This case demonstrates how the strategic use of hidden hinges can effectively enhance both functionality and operational convenience in industrial equipment.

Conclusion: Embracing the Strategic Value of Concealment

Concealed hinges transcend mere structural components to become pivotal elements in equipment design optimization. They harmoniously integrate functionality, safety, aesthetics, and brand value. Superior solutions deliver seamless appearance, elevated operational safety, and extended service life, generating greater value for enterprises. In the future, they will deeply integrate with smart technologies and advanced materials, unlocking further innovation potential for industrial applications.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What is the primary function of concealed hinges in industrial cabinets?

They are used when a flush appearance and airtight sealing are required. By hiding the mechanism inside the cabinet door, these hinges create a clean look while improving dust protection and resistance to tampering.

Are concealed hinges suitable for outdoor use?

Yes, if made from weather-resistant materials. For outdoor or humid environments, 304 or 316 stainless steel is recommended because of its excellent corrosion resistance and long-term durability.

How should they be maintained?

Maintenance is simple: check and tighten screws every 3–6 months, and clean and lubricate at least once per quarter. Regular care keeps movement smooth and extends service life.

What materials are used for heavy-duty applications?

Heavy-duty models are typically made from stainless steel or aluminum alloys. In particular, 304/316 stainless steel provides high load capacity and superior corrosion resistance for demanding environments.