HTAN является одним из ведущих производителей промышленных петель, ручек и защелок в Китае.

В медицинском оборудовании, промышленном оборудовании или устройствах отображения информации динамометрические шарниры играют важнейшую роль. Как Компания Frond Industries заявляет.: "Медицинские дисплеи, которые "парят" под любым углом в больницах, панели управления, которые устойчиво стоят на заводах... общий секрет, который стоит за ними, - это динамометрический шарнир". Моментные шарниры не только определяют плавность открытия оборудования, но и обеспечивают сохранение фиксированного угла наклона панелей и крышек после открытия, повышая безопасность эксплуатации. Эта статья посвящена трем основным типам динамометрических петель - фиксированным, регулируемым и скрытым, чтобы помочь вам в выборе проекта. Прежде чем приступить к изложению материала, давайте разберемся в принципиальных различиях между динамометрическими петлями и стандартными петлями.

Основы динамометрической петли: Чем они отличаются от обычных петель?

Как работают динамометрические петли

Динамометрическая петля включает в себя внутренний фрикционный или пружинный механизм, создающий постоянный или контролируемый момент сопротивления. Это позволяет дверным панелям или крышкам оставаться неподвижными под любым углом без провисания. В отличие от стандартных петель, моментные петли сохраняют свое положение автономно, не требуя дополнительной опоры. Это означает, что пользователи могут удерживать панели под любым углом без использования ограничителей или болтов. Шарниры для экранов ноутбуков - распространенное применение динамометрических шарнировЭкран остается устойчивым и не шатается, если его открыть на любой угол.

Характеристики устойчивости и безопасности

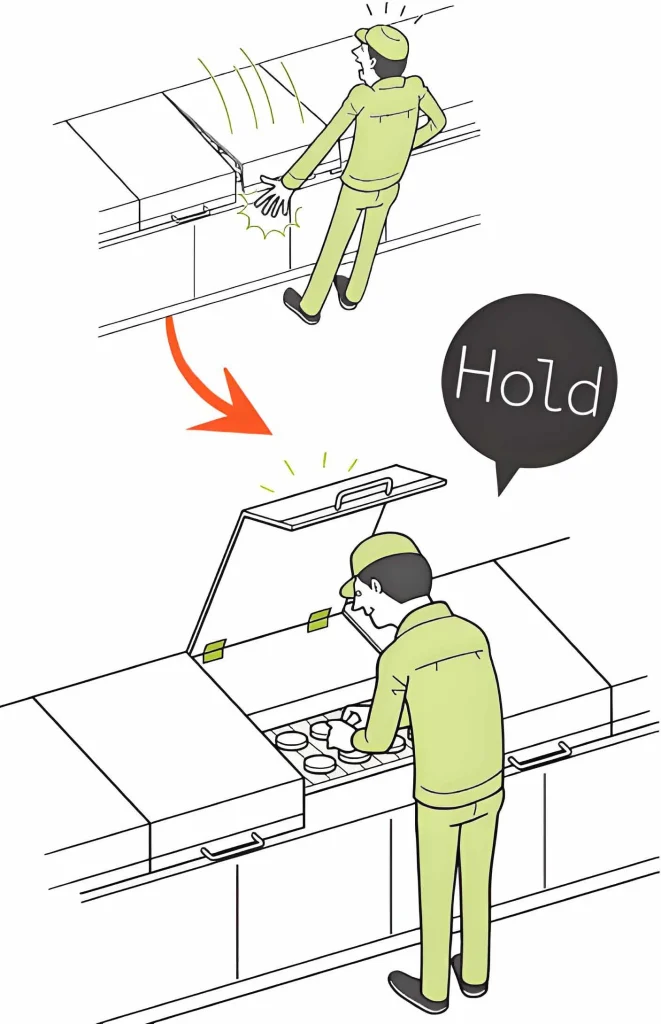

С крутящим моментом-шарниры-машины-доступа-двери-не-будут-внезапно-качаться-закрываться

Петли Torque могут фиксировать дверные полотна при любом угле открытия без дополнительной опоры. Это обеспечивает плавные и контролируемые движения открывания/закрывания. Одновременно моментные петли предотвращают удар и отскок при закрывании панели, снижая риск случайных травм. Например, без динамометрической петли дверная панель может резко захлопнуться, как показано в сценарии с работником слева. При использовании динамометрической петли панель остается надежно зафиксированной, предотвращая удар персонала. Основные преимущества динамометрических петель заключаются в их высокоточном управлении, возможности свободно стоять под любым углом и увеличенном сроке службы.

Рассмотрев основополагающие принципы, мы теперь подробно сравним три типа конструкций и сценарии их применения.

Петли с фиксированным моментом затяжки

Структура и принцип

В петлях с фиксированным моментом затяжки момент сопротивления задается при изготовлении и не подлежит последующей регулировке. Внутри них обычно используются такие компоненты, как фрикционные накладки, пружины или демпфирующие втулки, которые обеспечивают постоянный требуемый крутящий момент за счет определенной предварительной нагрузки или силы трения. [Проверка на долговечность должна проводиться в соответствии с ISO 9227]Такая конструкция обеспечивает стабильность крутящего момента на протяжении всего срока службы без смещения в результате многократных циклов открытия и закрытия.

Преимущества

Преимущества шарниров с фиксированным моментом затяжки очевидны: они готовы к использованию сразу после заводской настройки, не требуя последующей калибровки. Их простая и надежная конструкция обеспечивает длительный срок службы, что делает их идеальными для применения в системах с фиксированной нагрузкой. Не требуя обслуживания и практически не нуждаясь в регулировке, они экономически эффективны и хорошо подходят для массового производства и внедрения. Например, в дверях промышленных шкафов управления или панелях медицинских приборов, подвергающихся длительным фиксированным нагрузкам, фиксированные петли обеспечивают высоконадежное и долговременное позиционирование.[Процедуры проверки крутящего момента могут быть следующими ISO 6789 (калибровка динамометрических инструментов)]

Недостатки

Недостатком является невозможность регулировки крутящего момента после установки: если значение крутящего момента было выбрано неточно при спецификации, его нельзя увеличить или уменьшить впоследствии. Если установленный момент слишком мал, панель может провиснуть, а если слишком велик - ее будет трудно открыть. Поэтому на этапе выбора необходимо точно рассчитать требуемый крутящий момент, чтобы избежать ситуаций с недостаточным или избыточным крутящим моментом. Петли с фиксированным моментом затяжки подходят только для применения при стабильных нагрузках и частоте использования и не подходят для условий со значительными колебаниями спроса.

Типовые применения

Шарниры с фиксированным моментом затяжки часто встречаются в ноутбуках, промышленном оборудовании и автомобильных отсеках для хранения. В ноутбуках они поддерживают углы раскрытия экрана без посторонней помощи, а в промышленных шкафах управления или приборных панелях фиксируют положение дверей для доступа при обслуживании.

"Если вам требуется не требующее технического обслуживания и конструктивно простое решение, надежным выбором будут шарниры с фиксированным моментом затяжки. Однако если требуется гибкое управление крутящим моментом, лучше использовать регулируемые моментные петли".

Петли с регулируемым крутящим моментом

Структура и особенности

Шарниры с регулируемым моментом затяжки включают внутренние механизмы регулировки (например, винты, регулировочные болты), которые изменяют выходной крутящий момент в режиме реального времени путем изменения материала фрикционных накладок или силы предварительного натяжения. Сила трения, возникающая при вращении панели, может быть отрегулирована вручную в заданном диапазоне. Например, регулируемые фрикционные шарниры Sugatsune позволяют увеличивать или уменьшать сопротивление простым затягиванием или ослаблением регулировочного винта с помощью шестигранного ключа. Такая конструкция позволяет использовать одну петлю для панелей разного веса или различных сценариев использования.

Преимущества

Наиболее существенным преимуществом регулируемых шарниров является возможность регулировки крутящего момента и адаптивность: вы можете точно настроить сопротивление в соответствии с фактическими потребностями, учитывая различные нагрузки или предпочтения пользователей. Они идеально подходят для этапов тестирования НИОКР или сценариев с меняющимися требованиями, таких как лабораторное оборудование, медицинские дисплеи или высокотехнологичные терминалы, где калибровка может выполняться в режиме реального времени на основе изменений нагрузки во время использования. Это не только продлевает срок службы продукта, но и повышает удобство использования. Например, шарнир HTAN XG11-077 с регулируемым крутящим моментом позволяет свободно регулировать крутящий момент в диапазоне 1,0-5,0 Н-м, устраняя необходимость замены шарниров.

Недостатки

По сравнению с фиксированными петлями регулируемые петли имеют более сложную конструкцию и более высокую стоимость, поскольку требуют дополнительных компонентов и большей точности изготовления. Кроме того, наличие движущихся частей создает теоретический риск износа и смещения, что требует периодических проверок и точной настройки для поддержания работоспособности. В тех случаях, когда требуется минимальное обслуживание, регулируемые петли могут увеличить расходы на содержание.

Сценарии применения

Регулируемые шарниры подходят для сценариев высокого класса, требующих гибкого управления. В медицинском оборудовании они обычно служат опорой для кронштейнов дисплеев или диагностических терминалов, позволяя удерживать экраны под любым углом без провисания. Они также широко используются в точных приборах и дисплейных терминалах, обеспечивая плавное открытие/закрытие и повторяемость позиционирования. Шарниры с регулируемым моментом затяжки удобны в любых ситуациях, когда вес панели может меняться.

"Регулируемые петли предоставляют вам большую свободу управления. Когда эстетика и защита одинаково важны, скрытые петли становятся идеальным выбором".

Петли со скрытым моментом затяжки

Структура и особенности

Скрытые динамометрические петли Они имеют встраиваемую конструкцию и после установки остаются полностью скрытыми в дверных панелях или рамах. Обычно герметичные, они эффективно противостоят пыли и коррозии, что делает их пригодными для использования в сложных условиях. В их конструкцию входят прецизионные механизмы навески или несколько шарнирных рычагов, обеспечивающие плавную работу и аккуратный внешний вид даже при полном утапливании.

Преимущества

Главные преимущества скрытых петель - эстетика и бесшумная работа: при закрытой двери не видно ни одной детали петли, что создает чистую, единую поверхность для мебели или оборудования. Встроенные механизмы закрывания также снижают уровень шума и защищают внутренние компоненты от пыли и коррозии. В целом, скрытая конструкция позволяет сбалансировать требования к внешнему виду и надежные эксплуатационные характеристики.

Недостатки

По сравнению с открытыми петлями скрытые динамометрические петли имеют более ограниченный диапазон крутящего момента и обычно подходят для легких и средних условий эксплуатации. Установка также более сложна и требует специальных углублений как в дверной панели, так и в шкафу с точным выравниванием. Если место для установки не учтено при проектировании, модернизация становится чрезвычайно сложной.

Сценарии применения

Скрытые динамометрические петли используются в основном в помещениях, требующих высоких эстетических стандартов. В медицинских тележках, корпусах для приборов или элитной мебели скрытые петли обеспечивают гладкую поверхность, защищая при этом шарнирный механизм. Они также широко используются в бытовой электронике, складных устройствах премиум-класса (например, складных планшетах или ноутбуках) и роскошных автомобильных интерьерах для повышения качества.

"Теперь, когда мы рассмотрели характеристики трех типов, давайте быстро сравним их различия в таблице".

Сравнительная таблица характеристик для трех типов моментных петель

| Предмет сравнения | Петля с фиксированным моментом затяжки | Петля с регулируемым крутящим моментом | Петля со скрытым моментом затяжки |

|---|---|---|---|

| Регулировка крутящего момента | ❌ Нерегулируемый | ✅ Регулируемый | ⚙️ Фиксированный или ограниченный |

| Стоимость | 💲 Низкий | 💲💲 Средний | 💲💲💲 Высокий |

| Сложность установки | Легко | Умеренный | Выше |

| Внешний вид | Стандартный (видимый) | Стандартный (видимый) | Скрытый (чистый внешний вид) |

| Техническое обслуживание | Не требует настройки/обслуживания | Умеренная проверка и калибровка | Низкая (герметичная конструкция, но требует точной установки) |

| Общие приложения | Двери промышленных шкафов, экраны для ноутбуков | Медицинские стенды, кронштейны для демонстрации | Мебель, бытовая техника, бытовая электроника |

Приведенное выше сравнение подчеркивает их ключевые различия: Фиксированные петли отличаются низкой стоимостью и простотой установки, но имеют ограниченную функциональность; регулируемые петли обеспечивают гибкость при различных сценариях, но имеют более сложную конструкцию; скрытые петли имеют самую высокую стоимость и требовательны к установке, но обеспечивают оптимальный эстетический результат.

"Разобравшись в этих различиях, давайте рассмотрим, как шаг за шагом выбрать наиболее подходящий моментный шарнир для вашего проекта".

Как выбрать подходящий моментный шарнир для вашего проекта

Определите требования к движению

Сначала определите, требуется ли в вашем проекте "самозажим со свободным углом". Если компоненты должны сохранять определенный угол после освобождения без дополнительной поддержки, динамометрический шарнир необходим. Если требуется частая регулировка крутящего момента или вес панели может меняться, рассмотрите вариант регулируемого динамометрического шарнира. Если достаточно одной настройки крутящего момента и требуется минималистичный дизайн, выбирайте фиксированные или скрытые петли.

Рассчитайте диапазон крутящего момента

Рассчитайте необходимый крутящий момент (сила × длина рычага), исходя из веса дверной панели и длины рычага. Например, если панель весит 5 кг, а центр тяжести находится на расстоянии 0,3 м от петли, каждая петля должна обеспечивать крутящий момент приблизительно (5 × 9,8 × 0,3) / 2 ≈ 7,35 Н-м. Обычно рекомендуется добавить к расчетному значению запас прочности 10-20%, чтобы обеспечить плавную фиксацию панели в нужном положении.

Учитывайте условия эксплуатации

Оцените, насколько рабочая среда подвержена таким факторам, как влажность, высокие температуры, соляной туман или химическая коррозия. Как уже упоминалось в Нанкине, петли из нержавеющей стали обладают высокой коррозионной стойкостью, а герметичные конструкции защищают внутренние механизмы трения от эрозии. Для работы на открытом воздухе или в суровых условиях выбирайте материалы для петель и обработку поверхности со специальной защитой (например, уплотнение, степень защиты IP).

Баланс между эстетикой и ремонтопригодностью

Для проектов, требующих первоклассной эстетики, отдайте предпочтение скрытым динамометрическим петлям. Регулируемые петли удобны для частых регулировок и тестирования. Фиксированные петли подходят для применения в условиях, не требующих обслуживания после установки и отличающихся стабильностью. Независимо от выбора, проведите всестороннюю оценку с учетом пространства для установки, расположения отверстий и долговечности.

"После выполнения этих оценок вы должны иметь четкое представление о том, какой тип петли лучше всего подходит для вашего проекта".

Применение в реальной промышленности

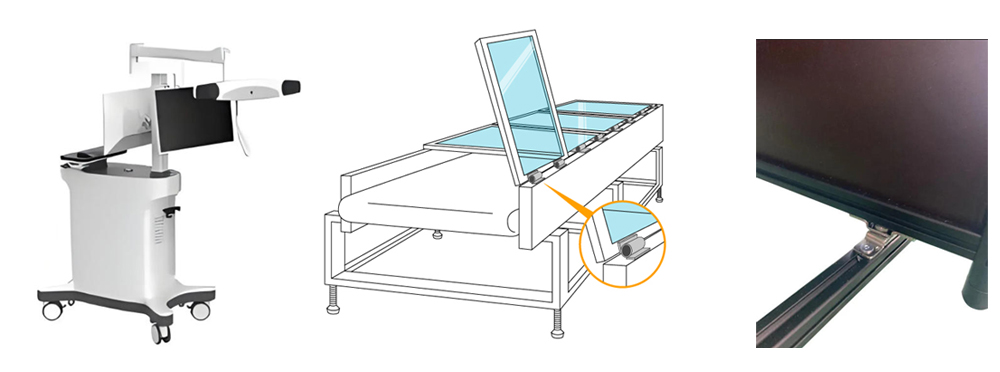

Слева направо: применение динамометрических шарниров в медицинском оборудовании, промышленном оборудовании и бытовой электронике

Медицинское оборудование

Регулируемые динамометрические шарниры обычно используются на кронштейнах дисплеев в операционных или диагностическом оборудовании, позволяя врачам регулировать и фиксировать углы наклона экрана одной рукой для удобства визуального восприятия. В таких устройствах, как смотровые столы и сканеры для визуализации, используются динамометрические шарниры для точного позиционирования и гибкого управления.

Промышленное оборудование

В шкафах и дверях шкафов управления обычно используются петли с фиксированным моментом затяжки. Эти петли предварительно настраиваются на определенный крутящий момент, надежно поддерживая тяжелые двери без дополнительных креплений. Благодаря высокой прочности и низкой потребности в обслуживании они широко используются в производственных линиях и панелях станков.

Бытовая электроника

Скрытые динамометрические петли становятся все более популярными в высококлассных складных устройствах и мебели. В качестве примера можно привести смартфоны и планшеты, где они обеспечивают одновременно эстетичный вид и стабильную опору.

"Разобравшись с областями применения, давайте рассмотрим, как обеспечить оптимальную работу шарниров при длительном использовании".

Рекомендации по техническому обслуживанию и оптимизации производительности

Регулярная уборка

Держите область вокруг шарнира в чистоте, чтобы предотвратить попадание пыли или мусора во фрикционный механизм, что может повлиять на мощность крутящего момента.

Проверка на износ

Периодически проверяйте затяжку и состояние износа петли, особенно регулировочных винтов на регулируемых петлях. Незамедлительно подтягивайте все ослабленные винты.

Регулировка калибровки

Для петель с регулируемым крутящим моментом периодически калибруйте значения крутящего момента в соответствии с руководством пользователя. При обнаружении недостаточного крутящего момента выполните точную настройку для обеспечения стабильной работы.

Защита от смазывания

Использование рекомендованных производителем смазок или ингибиторов ржавчины эффективно продлевает срок службы петель. Высококачественные петли отличаются точностью конструкции и демонстрируют минимальное ухудшение характеристик даже после десятков тысяч циклов. Например, петли премиум-класса Динамометрические петли из нержавеющей стали Сохраняют постоянный крутящий момент после десятков тысяч циклов благодаря прецизионным поверхностям трения и конструкции пружин.

Регулярное техническое обслуживание обеспечивает оптимальную работу динамометрических шарниров в течение длительного времени и снижает частоту отказов[Регулярная очистка, проверка на износ и смазка являются обязательными.

Циклы технического обслуживания должны соответствовать ISO 281 методы оценки срока службы механических подшипников].

Распространенные ошибки и методы их предотвращения

Недостаточный крутящий момент

Заниженное значение крутящего момента может привести к неожиданному провисанию дверных панелей, а чрезмерно высокое значение может препятствовать открыванию/закрыванию. Всегда делайте выбор на основе расчетных результатов с запасом прочности.

Неправильная ориентация установки

Обратите внимание на направление установки однонаправленных моментных петель. Пружинные петли имеют фиксированную ориентацию; их установка в обратном направлении приведет к устранению ожидаемого усилия пружины. Внимательно прочитайте инструкцию или маркировку производителя после покупки и устанавливайте в соответствии с направлением стрелки.

Пренебрежение операционной средой

Различные условия требуют различных характеристик материала. Использование пластиковых петель во влажной или коррозийной среде приведет к их быстрому разрушению. Всегда выбирайте подходящие материалы (например, нержавеющую сталь 304/316) и способы обработки поверхности в зависимости от условий эксплуатации.

Игнорирование позиционирования точки поворота

При установке убедитесь, что положение петли совпадает с центром нагрузки. Неправильное расстояние между монтажными отверстиями или несбалансированное распределение нагрузки приведет к снижению эффективности крутящего момента и срока службы. Зарезервируйте достаточное пространство и добейтесь сбалансированного расположения на этапе проектирования.

"Избежание этих ошибок не только продлевает срок службы шарниров, но и повышает общую стабильность изделия".

Резюме и рекомендации к действию

Петли с фиксированным моментом затяжки идеально подходят для применения в условиях стабильной нагрузки, где не требуется регулировка, обеспечивают стабильную работу и минимальное обслуживание - идеальное решение для промышленных панелей и повседневных устройств.

Шарниры с регулируемым крутящим моментом подходят для проектов, требующих точной настройки или переменного крутящего момента, например, для медицинского или прецизионного оборудования, где гибкость имеет ключевое значение.

Скрытые динамометрические петли сочетают в себе функциональность и эстетику, обеспечивая скрытое, плавное и бесшумное движение мебели, электроники и изделий, ориентированных на дизайн.

Правильный выбор динамометрического шарнира повышает безопасность, долговечность и удобство использования оборудования, обеспечивая надежную работу и изысканный внешний вид вашей конструкции.

Часто задаваемые вопросы (FAQ)

Вопрос 1: Как определить, какой динамометрический шарнир мне нужен?

О: Сначала уточните требования к применению: - Если требуется только фиксированное демпфирование без последующих регулировок и нагрузка относительно стабильна, выбирайте шарнир с фиксированным моментом. - Если проект находится в стадии НИОКР или включает в себя несколько сценариев нагрузки, требующих гибкой регулировки, лучше выбрать шарнир с регулируемым моментом затяжки. - Если для вас важен внешний вид и вы предпочитаете скрытые петли, выберите скрытый моментный шарнир, который обеспечивает чистый и эстетичный дизайн.

Вопрос 2: Каков типичный диапазон регулировки для шарниров с регулируемым моментом затяжки?

О: Это зависит от размера и конструкции петли. Большинство регулируемых петель имеют крутящий момент в диапазоне примерно 0,1-7 Н-м. Некоторые модели премиум-класса могут достигать 10 Н-м и выше. Например, Haitan XG11-077 Регулируемый шарнир серии предлагает диапазон 1,0-5,0 Н-м, а динамометрические шарниры таких брендов, как Sugatsune, поддерживают диапазон 1-20 Н-м. Для точного выбора обратитесь к техническим характеристикам производителя.

Вопрос 3: Исчезает ли со временем крутящий момент у динамометрических шарниров?

О: Крутящий момент шарниров может слегка изнашиваться после длительного и высокочастотного использования, но у шарниров премиум-класса он минимален. Испытания показывают, что высококачественные шарниры сохраняют стабильную производительность в течение 10 000 циклов; некоторые прецизионные шарниры имеют срок службы, превышающий десятки тысяч циклов, при этом ухудшение характеристик находится в допустимых пределах. Правильное обслуживание и смазка продлевают срок службы. При очень частом использовании следует предусмотреть дополнительное сопротивление в качестве запаса прочности.

Q4: Сложно ли устанавливать скрытые динамометрические петли?

О: По сравнению с обычными открытыми петлями, скрытые петли требуют более высокой точности установки. Это связано с тем, что для установки петли необходимо предварительно вырезать соответствующие углубления как в дверной панели, так и в корпусе шкафа. Если места установки запланированы на этапе проектирования, установка таких петель вполне выполнима, но требует точной обработки. Модернизация значительно усложняет процесс.

Q5: Могу ли я оценить требуемый крутящий момент, исходя из веса защитной пластины?

О: Да, используя следующую приблизительную формулу: Крутящий момент (Н-м) = Вес (Н) × Горизонтальное расстояние от центра тяжести панели до петли (м) ÷ Количество петель. Например, для дверной панели весом 5 кг с центром тяжести на расстоянии 0,3 м от петли потребуется общий крутящий момент ≈ 5 × 9,8 × 0,3 ≈ 14,7 Н-м. При использовании двух петель каждая петля должна обеспечивать ≈ 7,35 Н-м. Мы рекомендуем добавить к рассчитанному результату запас в 10-20% для учета неопределенностей (например, погрешности измерений, силы удара). При выборе шарниров обратитесь к кривой крутящего момента производителя или свяжитесь с его инженерами напрямую для подтверждения результатов.

Q6: Где можно получить конкретные данные или образцы крутящего момента?

О: Большинство производителей петель размещают на своих официальных сайтах руководства по эксплуатации, технические характеристики или инструменты для выбора в режиме онлайн для бесплатной загрузки. Вы также можете напрямую связаться с производителями или местными дистрибьюторами и запросить образцы для тестирования. Такие компании, как Sugatsune, Southco и Haitan, предлагают обширные каталоги продукции и техническую поддержку. Как официально рекомендует компания Sugatsune, вы можете "просмотреть их онлайн-ресурсы, включая каталоги продукции, видеоролики и файлы CAD", или "связаться с ними для получения помощи", чтобы получить необходимые данные о крутящем моменте и образцы.

Благодаря правильному выбору и установке динамометрические петли обеспечат надежное позиционирование и безопасность вашего проекта. Для получения дополнительной технической поддержки, не стесняйтесь консультироваться с нашими инженерами.