HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

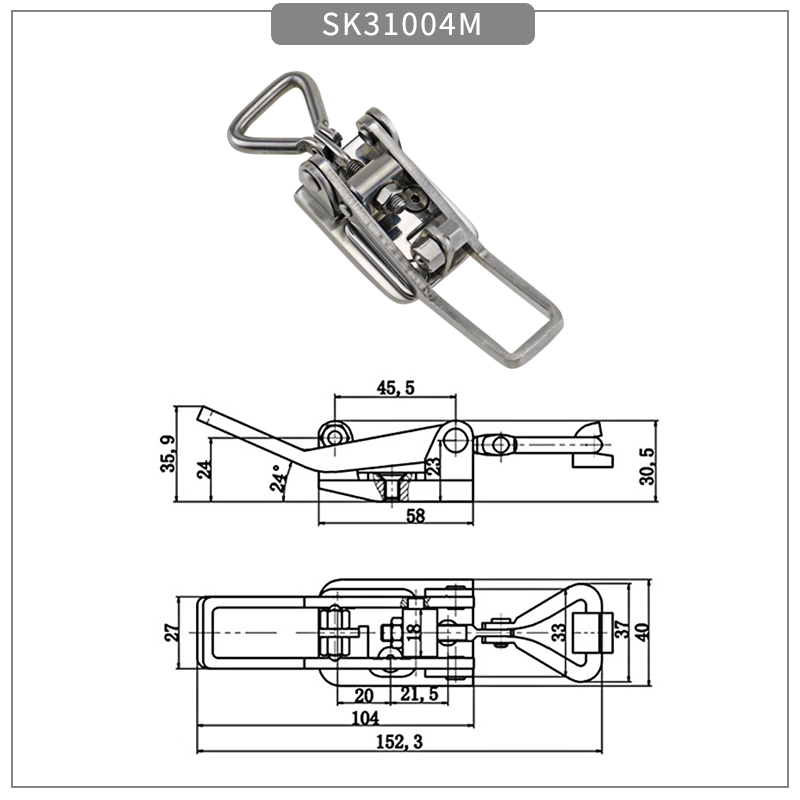

PRODUCT INFORMATION

- Manufacturer: HTAN

- Model: SK31004M

- Material: stainless steel

- Surface treatment: mirror

- Application Scenario: Tin cabinet, heavy duty equipment cabinet, control cabinet

- Whether to support customisation: Yes

Description

Product Features

STRONG MATERIAL: Heavy duty equipment cabinet latch is made of stainless steel which is made of high strength metal material

SURFACE TREATMENT: after mirror treatment, the surface is smoother, brighter and easy to clean.

Adapt to the environment: made of corrosion-resistant stainless steel, adapt to all environments.

Application Scenarios

In the field of construction and engineering machinery: toolboxes and equipment boxes of engineering machinery (such as cranes, loaders, etc.) at construction sites

Energy facilities: in power stations, substations, power distribution cabinets, energy storage equipment cabinets and other facilities.

In the field of industrial equipment: widely used in control cabinets and electrical cabinets of industrial equipment such as large machine tools, injection moulding machines, presses, etc.

.png)

Frequently asked questions and answers about spring-loaded traction locks for large equipment

Q: Spring-loaded traction locks jam during use

A: Clean the inside of the lock to remove dust and impurities.

Q: Spring-loaded traction locks loosen after a long time of use.

A: Check the spring tension. If the spring tension is insufficient, try adjusting the spring preload.

Q: Spring loaded traction locks do not work properly in low temperatures.

A: Select a 304 stainless steel spring made of low temperature resistant material with a temperature range of -10°C to 100°C4.

Q: Spring-loaded traction locks are easily damaged under high loads

A: When designing and installing, ensure that the lock is installed in a location and manner that spreads the load and reduces the force at a single point.

Q: Spring-loaded traction locks are prone to rust in wet environments.

A: Clean the lock regularly to remove moisture and dirt from the surface. Apply anti-rust oil or use a rust inhibitor to protect the lock from corrosion.

.png)

.png)

.png)

.png)

-150x150.png)

-150x150.png)

-150x150.png)

-150x150.png)

-150x150.png)

-1-768x768.png)

-768x768.png)