HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Industrial Handles Manufacturer

Materials: Industrial handles are typically made from metals such as stainless steel and carbon steel.

Surface treatments: Galvanizing, chrome plating, painting, etc

HTAN is a professional industrial handle manufacturer with a 7,000m² meter factory. It has a complete lean supply chain system that includes design, research and development, casting, die-casting, stamping, CNC machining, assembly, and sales.

Want to know how to compress lead times?

The Ultimate Guide to Industrial Handles

Industrial handles are manual operating components used on industrial equipment, machinery, and similar devices. Their primary function is to help users open, close, pull, or move related parts of the equipment, such as cabinet doors, drawers, and control panels. They are an important part of human-machine interaction in industrial equipment, and the design of the handle directly affects the convenience and efficiency of operating the equipment.

Materials Used for Industrial Handles

Stainless Steel (Stainless Steel Handles)

Stainless steel is one of the most commonly used materials for industrial handles due to its excellent corrosion resistance. In environments such as food processing, chemical plants, and pharmaceutical facilities—where hygiene and rust prevention are critical—stainless steel handles help prevent contamination and ensure long-term durability.

Carbon Steel (Carbon Steel Handles)

Carbon steel handles are well known for their high strength and outstanding toughness. Composed primarily of iron and carbon with a relatively high carbon content, they provide strong hardness and impact resistance. This makes them ideal for heavy-duty industrial applications, such as operation doors on large machinery or electrical cabinets, where frequent pulling and strong impacts are common.

Aluminum Alloy (Aluminum Alloy Handles)

Aluminum alloy handles are lightweight while still providing reliable strength. One of the biggest advantages of aluminum alloy is its ease of processing, allowing it to be formed into complex shapes with high precision. In industries such as aerospace, where equipment weight must be strictly controlled, aluminum alloy handles are an excellent option for reducing overall load without sacrificing functionality.

Engineering Plastics & Composite Materials

Engineering plastics—such as ABS (Acrylonitrile Butadiene Styrene) and PC (Polycarbonate)—are valued for their high strength, impact resistance, and overall performance. These materials can withstand collisions during transportation and operation without cracking easily, making them suitable for electronic equipment housings and similar applications.

In addition, engineering plastics can be molded into various colors and shapes, providing greater design flexibility and improved aesthetics. They also offer excellent insulating properties, making them an ideal choice for industrial equipment that requires electrical safety.

Types of Industrial Handles

| Classification methods | Classification of industrial handles | specificities |

| Classified by material | Plastic Industrial Handles | Low cost, lightweight, with some corrosion resistance, and available in various colors and shapes. For example, small handles on instrument enclosures or the handles on small plastic toolboxes |

| Stainless steel industrial handles | Sturdy and durable, with excellent corrosion resistance and a shiny appearance. Suitable for applications that require high handle strength and environmental resistance, such as handles on food processing equipment or medical device enclosures. | |

| Aluminum Industrial Handles | Lightweight, high strength, easy to mold into various shapes, and with good heat dissipation properties. Commonly used in electronic device enclosures, industrial control cabinets, and similar applications | |

| Zinc Alloy Industrial Handles | Complex shapes can be produced through die-casting, with various surface finishing options, such as plating for an attractive appearance. These are commonly found on high-end industrial equipment or display units. | |

| Classified by shape | Long Industrial Handle | The handle is strip-shaped, making it easy to grip and operate. It offers various installation methods and is widely used on large industrial cabinet doors or maintenance doors, providing convenience for opening and closing large panels |

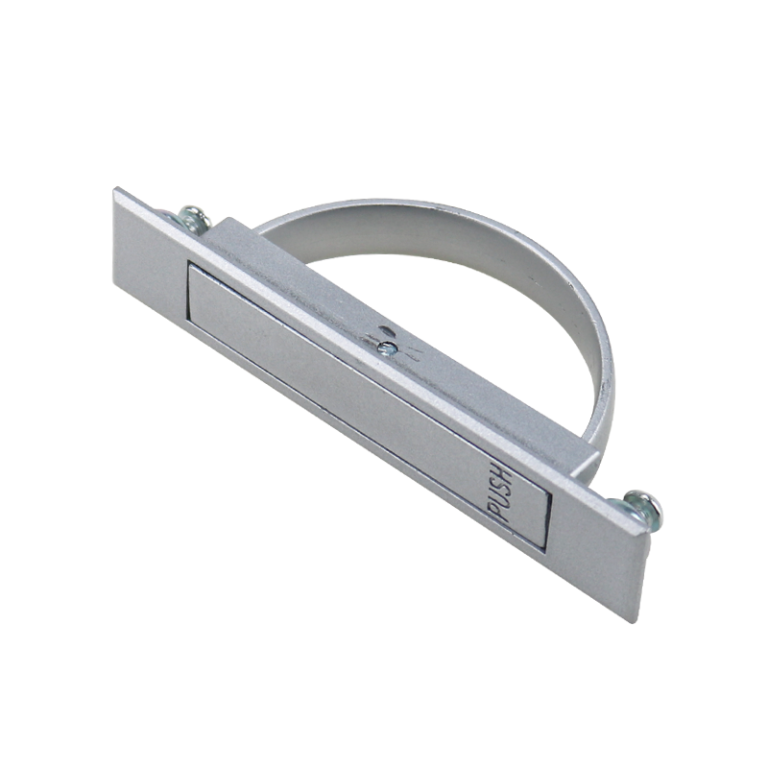

| Bow-shaped Industrial Handle | The shape is similar to a bow, with the central part designed for gripping and the sides for installation. Its ergonomic design provides a comfortable grip, making it commonly used on small equipment boxes that require frequent opening | |

| Round Industrial Handle | The handle is round in shape, available as a single circle or a combination of multiple circles. It has a simple appearance and is operable by rotation. Some round handles even feature additional functions, such as scales, commonly found on adjustment knob handles on mechanical control panels. | |

| Shaped Industrial Handle | The shape is irregular, customized based on the overall design of the equipment or specific functional requirements. For example, handles on industrial product enclosures with a sci-fi or artistic style, featuring unique and attention-grabbing designs. | |

| Classified by purpose | Industrial Handle for Cabinet Door | Primarily used for cabinet doors on various industrial equipment, making it easier to open and close the doors. The handle needs to meet certain strength and operability requirements to ensure the cabinet door functions properly, such as handles on distribution panel doors |

| Industrial drawer handles | Installed on industrial drawers, with dimensions typically designed based on the size and weight of the drawer to ensure easy operation. For example, handles on tool drawers | |

| Industrial handles for equipment operation | As part of the equipment control components, used to adjust parameters, start or stop the equipment, and other functions. These handles may also feature labels, scales, or other indicators, such as functional handles on machine tool control panels |

Surface Treatments for Industrial Handles

- Chrome Plating: Chrome plating is a common surface treatment for industrial handles. It creates a hard and wear-resistant layer that gives the handle a shiny, mirror-like finish. This finish remains intact even with frequent handling and friction.

- Nickel Plating: Nickel plating provides excellent corrosion and oxidation resistance. The nickel layer forms a protective film on the handle surface, preventing oxidation and chemical corrosion.

- Zinc Plating: Zinc plating is a more economical surface treatment. The zinc layer acts as a sacrificial anode to protect the base material; when the zinc corrodes, the handle remains protected.

- Powder Coating: Powder coating involves applying powder paint electrostatically to the surface and then curing it at high temperatures. This provides a durable and customizable finish available in various colors to meet industrial design and equipment color requirements.

- Liquid Coating: Liquid spray coating involves spraying liquid paint onto the handle’s surface, achieving finer and more detailed finishes, such as gradient colors or transparent coatings.

- Anodizing: Mainly used for aluminum and aluminum alloy handles, anodizing creates a dense oxide layer on the handle’s surface, providing excellent hardness and wear resistance.

- Brushed Finish: A brushed finish is created by grinding the surface of the handle to produce linear textures. This treatment gives the handle a distinctive metal feel and luster, enhancing its aesthetic appeal.

- Passivation: Primarily used for stainless steel and other metal handles, passivation forms a protective passive layer on the surface to improve corrosion resistance.

Conclusion:

Industrial handles are widely used across various industrial scenarios, including industrial equipment, large machinery, and cabinet doors. Their main purpose is to assist in opening, closing, pulling, or moving parts related to industrial facilities. For instance, they provide a convenient grip for applying force when opening and closing cabinet doors on industrial enclosures, or help operators handle control panels when moving large industrial equipment.

Application scenarios of handles

Application Industries

Frequently Asked Questions

Contact to Get Free Sample

What’s our customer’s Opinion?

We’ve been using HTAN” hinges and latches for ourelectrical cabinets nearly 10 years, and the quality hasconsistently impressed us. Their products are robust, performwell under stress, and have truly simplified our productionprocesses. The HTAN team is also remarkable for theirattention to detail and quick response times.

Switching to HTAN for our network communicationcabinets was a game changer. The precision and aesthetics oftheir hinges and latches have significantly improved the overalldesign and usability of our products. Their team’s expertise andcommitment to excellence are evident in every interaction

“From the initial design consultation to the final delivery, ourexperience with HTAN has been outstanding. Theirproactive customer service and the technical support theyprovide have made them an indispensable part of ourproduction line.