HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

A unique kind of hinge known as torque hinges is manufactureed to allow angular motion and maintain stability.Widely used in various uses including vehicle parts and building manufactures, these hinges are utilized.This article discusses the details of Torque Hinges, including their manufacture, uses, advantages, and usual requirements associated with their use.

To ensure optimal functionality and durability, several elements must be considered when choosing a torque hinge.The main requirements for selecting the right Torque Hinge for your specific application will be discussed in this section.The primary concern when selecting a Torque Hinge is its carrying capacity and torsional resistance.

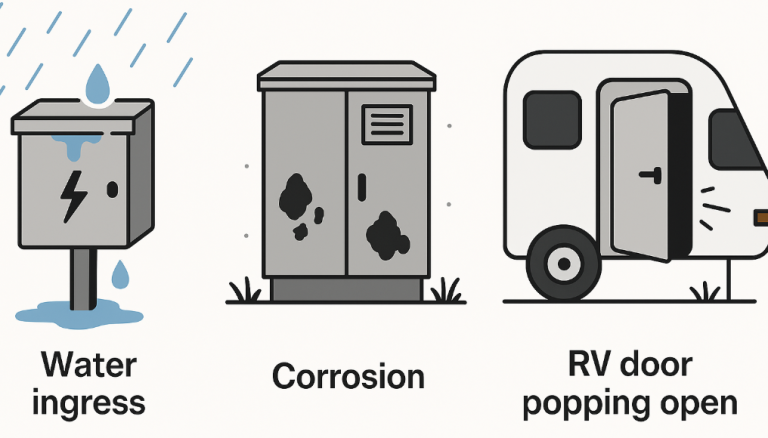

This section will explore the importance of these elements and their relation to the hinge’s functionality.The service life of a Torque Hinge can be significantly effected by the setting in which it will be used.This section will discuss the importance of rust resistance and the various components available for hinge manufacture.

The durability and functionality of a disc torque hinge depend on correct installation and routine maintenance.This section will cover the installation procedure and provide advice for maintaining the hinge in best condition.The following specifications must be take into accounted in choosing a disc torque hinge:

1. Size and mounting arrangement: aligning the measures and mounting arrangement of the hinge to the specifications of your application guarantees suitability and correct fit.

- bearing bearing capacity: A hinge must be capable of carrying the anticipated weight without encountering overstress or breakdown.

- torsional resistance: engineered to withstand torsional forces that can occur because of rotational movements or external forces, the hinge must be torsion-resistant.

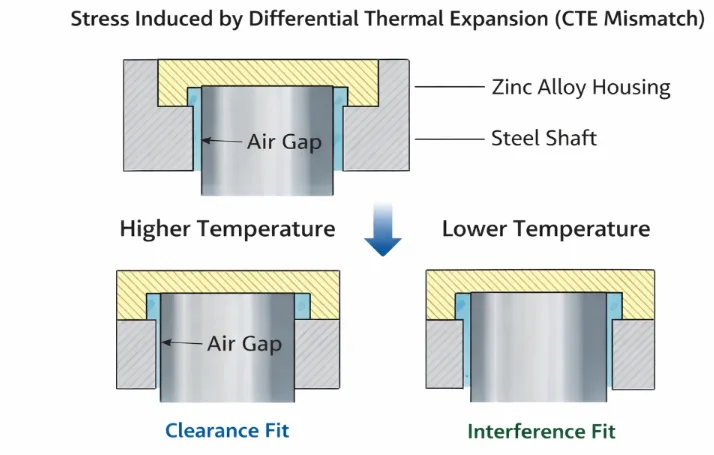

- functioningal temperature spectrum: appropriate for the functioningal temperature spectrum of your application, the hinge must guarantee reliable functionality under different conditions.

Key determinants determining the fitness of a disc-type torque hinge for a particular use are its capacity to bear load and torque withstanding ability.subject to the stress of typical use, a hinge with insufficient capacity to bear load may fail, resulting in damage to equipment or safety risks.Therefore, it is fundamental to choose a hinge with a capacity to bear load that exceeds the expected working load.

torque withstanding ability is vital for hinge selection employed in uses involving rotary motion, like entryways or barriers.The hinge need to be intended for handle the anticipated torque loads without any distorting or failing.Vital for hinge selection employed in severe or outside conditions, corrosive tolerance in which a considerable factor to think about.

for hinge selection in corrosive atmospheres like sea water or chemicals, materials that provide superior corrosive tolerance require use.disc-type torque hinges typically utilized including materials like inox steel, aluminium, and galvanized steel, every with its pros and cons that need to be considered depending on the particular use requirements.

The durability and efficiency of a disc hinge depend on correct installation and regular care.During installation, it is important to follow the instruction manual carefully to guarantee proper alignment and operation.early wear or malfunction can result from incorrect installation.Regular care including oil and checkup can extend the lifespan of a disc hinge.

Maintain the hinge by keeping it tidy and free of dirt, and applying oil as recommended by the manufacturer.Many uses depend on disc hinges as vital parts, providing trustworthy efficiency and stability.Understanding the choice factors, -bearing ability, material choice, and care requirements, you can choose the right disc hinge for your individual requirements.

By doing so, you can guarantee optimal efficiency and durability for your hinge, which contributes to the overall achievement of your initiative.

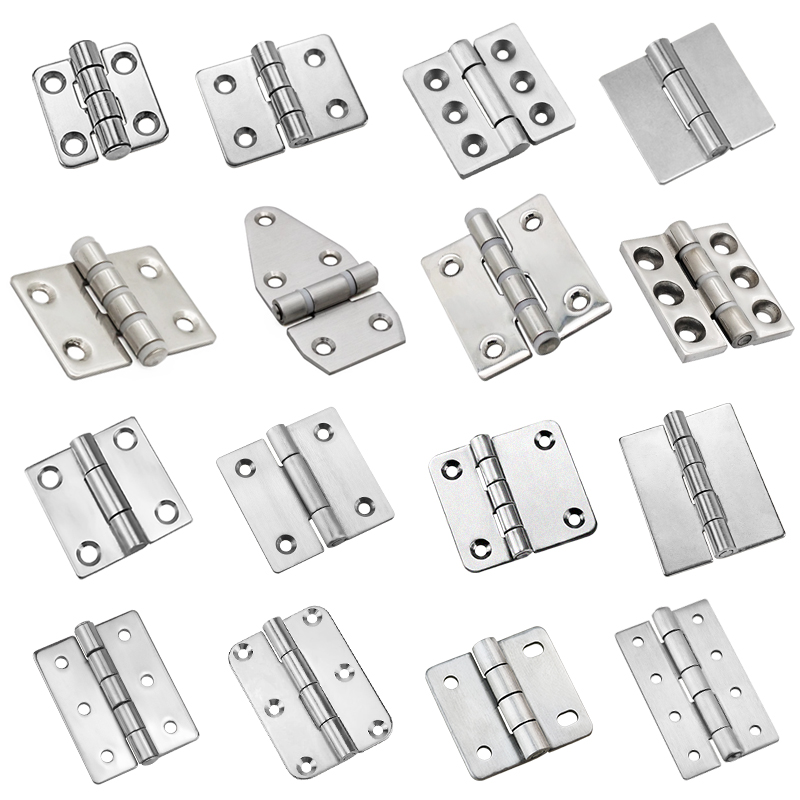

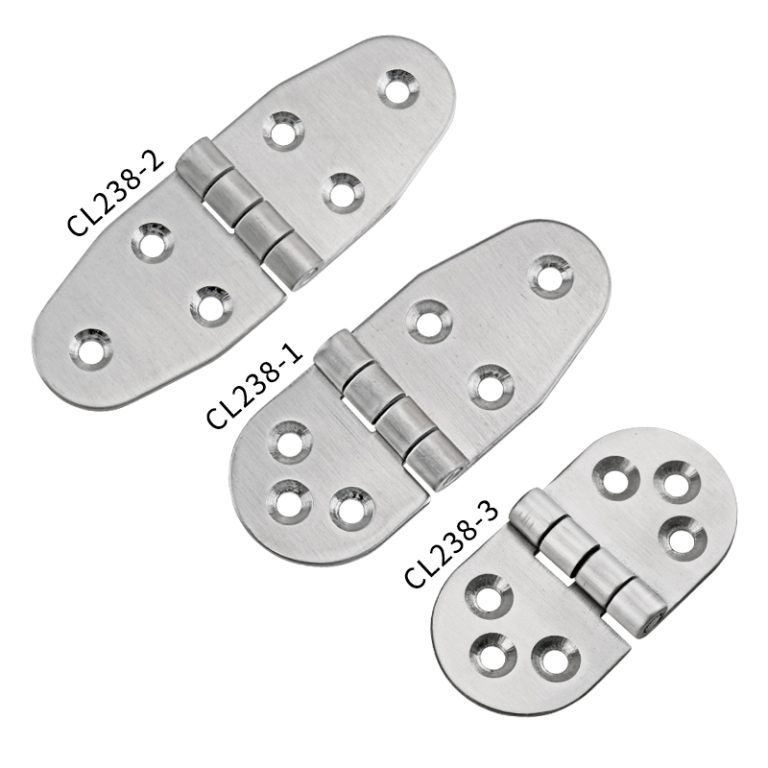

Recommend several widely used HTAN hinges

Torque hinges with 11mm overcurrent hole

360-Degree Rotation with Multi-Stop Positioning Designed with an 11mm cable pass-through hole, offering a wide torque range from 1.0 N·m to 6.0 N·m. Ideal for applications requiring flexible rotation, such as medical diagnostic equipment, industrial robots, production line transfer devices, and more.

Small Adjustable Stop Damping Torque Shaft

Small Adjustable Stop Damping Torque Shaft, made of iron, used in medical equipment, industrial equipment, furniture items and so on, HTAN is a professional hinges manufacturer, torque hinges with strict quality and fast delivery, HTAN has passed ISO certification, you can buy and use with confidence.

Folding Thickened Hinge CL238-1/2/3 Available in stainless steel and iron materials, with surface treatments such as brushed, mirror finish, and galvanized. The thickness is 2.5mm. It is widely used in distribution boxes, toolboxes, equipment cabinets, switch cabinets, and more.

Removable switchboard hinge CL248, available in stainless steel, iron, weldable, perforated for installation, mainly used in control cabinet, base cabinet, switch cabinet, Rittal cabinet, etc.