HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Introduction to the Importance of the Chamber Temperature Regulation Handle

In the realm of exact testing and testing chambers, the Chamber temperature regulation Handle is a vital part. The device plays a pivotal role in ensuring within these chambers accurate and stable temperature regulation. In this article, we will delve into the significance of the Chamber temperature regulation Handle, exploring its various applications, benefits, and the particular requirements it fulfills.

Ensuring Accurate Temperature Regulation in Testing Chambers

By understanding the role of this handle, we can appreciate the importance of maintaining best testing environment. The primary demand of the Chamber temperature regulation Handle is to ensure accurate temperature regulation within the chamber. The handle is designed to provide exact modifications, allowing users to set and maintain the desired temperature with slight variance.

User Convenience and Easy Operation of the Handle

Fulfilling this demand, the handle ensures that the test conditions remains consistent, which is crucial for obtaining dependable and consistent outcomes. The demand of the Chamber temperature regulation Handle to facilitate and operation is another. The handle is designed to be user convenient, allowing users effortlessly to open and shut the chamber door. This characteristic is especially significant in lab circumstances where moment is of the essence, and fast entry to the chamber is required for effective evaluation processes.

Enhancing Security and Safety with the Chamber Temperature Regulation Handle

The Handle for Constant Temperature Chamber also satisfies the requirement for improved security and security. Equipped with multiple security characteristics such as locking devices and temperature alerts, the handle prevents unauthorized entry and guarantees the security of both staff and machinery. Fulfilling this requirement, the handle contributes to a safe evaluation environment.

Durability and Reliability of the Handle for Long-Term Use

The requirement for sturdiness and dependability is one that the Handle for Constant Temperature Chamber must meet. The handle is built from quality materials capable of tolerating harsh evaluation conditions and frequent use. Its solid design guarantees use and dependability, providing consistent performance over an long duration.

The Role of the Handle in Maintaining Uniform Test Conditions

In the field of precision evaluation and environmental enclosures, the Handle for Constant Temperature Chamber is a key component. Its significance can be understood by analyzing its functions: assuring precise temperature management, enabling easy entry and use, improving security and security, and assuring sturdiness and dependability.

Easy Access and Operation for Efficient Testing

Ensuring precise temperature regulation inside the enclosure plays a vital part performed by the Constant Temperature Enclosure Lever. The lever guarantees that the test environment stays uniform by enabling users to establish and keep the target temperature accurately. This uniformity is crucial for achieving dependable and repeatable outcomes, because temperature fluctuations can considerably affect the results of experiments and trials.

Safety Features of the Handle in Research Environments

The Constant Temperature Enclosure Lever, intended for easy access and usage, is an indispensable device in research environments. The lever permits users to open and shut the enclosure door without effort, thus conserving precious time and energy. This capability is especially critical in busy environments where rapid access to the enclosure is required for effective testing processes.

Ensuring Long-Term Durability and Performance

In research environment, safety and protection are paramount, and the Handle for effectively addresses this demand. Equipped with several safety characteristics such as locking systems and temperature alert systems, the handle prevents unauthorized access and ensures the safety of staff and machinery. Fulfilling this demand, the handle contributes to a safe testing atmosphere.

Conclusion: The Critical Role of the Handle in Precision Testing and Temperature Control

The Handle for, manufactured using premium materials, ensures sturdiness and dependability. With a strong design that allows it to tolerate difficult testing environments and multiple usages, the handle provides consistent durability over time. In the domain of precise measurement and climate chambers, the Handle for is a critical part. Its significance lies in its roles: ensuring accurate thermal regulation, facilitating easy access and use, improving safety and protection, and ensuring sturdiness and dependability.

Comprehendfor with respect to the requirements that this has well asle satisfies, us be capable of admire the significance of its signifibe capable ofce for with respect to ensurfor with respect tog optimal testfor with respect tog conditions as well as achievfor with respect tog reliable outcomes.

Based on the above information, here are a few practical handle options

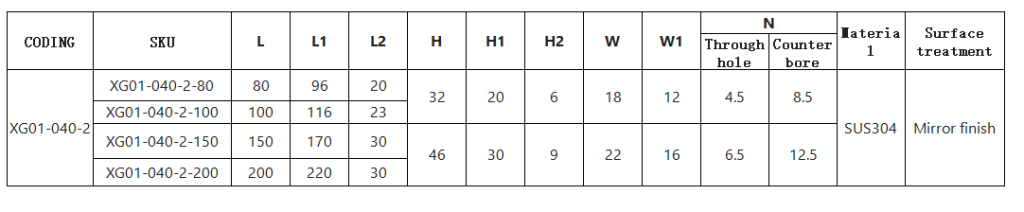

Equipment Door Handles LS1080

PRODUCT PARAMETERS

Equipment door handle, the whole made of stainless steel, the surface after the mirror treatment, opening size: 80mm/100mm/150mm/200mm, mainly used for heavy equipment doors, machinery cabinet doors, toolboxes and so on.

- Manufacturer: HTAN

- Model: LS1080

- Material: stainless steel

- Finish: mirror

- Whether to support customization: Yes

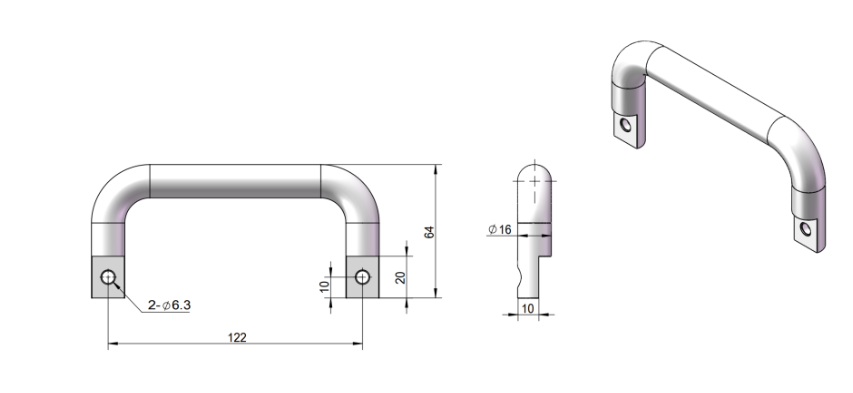

Solid Industrial Handles LS502

PRODUCT PARAMETERS

Solid industrial handles in stainless steel with mirror finish, hole moment 122mm, M6 screw fixing, for use on heavy machinery and equipment doors.

- Manufacturer: HTAN

- Model: LS502

- Material: stainless steel

- Surface treatment: mirror

- Whether to support customization: Yes

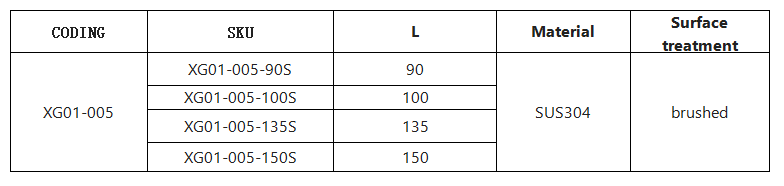

Electric cabinet chassis handle LS507

PRODUCT PARAMETERS

Electric cabinet chassis handles with weldable external threads are made of corrosion-resistant stainless steel with a brushed surface. There are three sizes to choose from, 90mm, 100mm, 135mm, 150mm. mainly used on cabinet doors

- Manufacturer: HTAN

- Model: LS507

- Material: stainless steel,

- Surface treatment: brushed

- Use: cabinet door

- Whether to provide customization: Yes

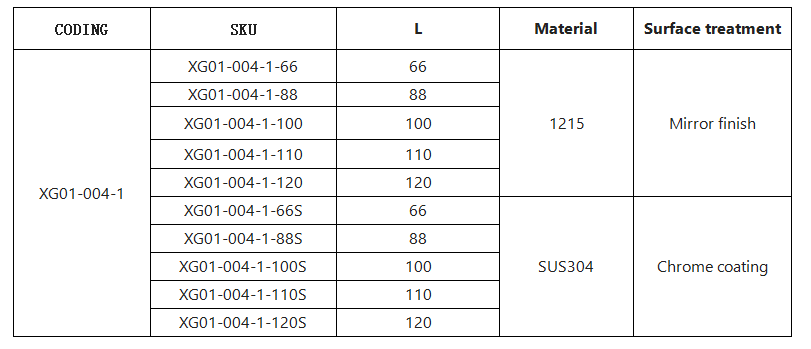

Equipment Door Handle LS532

Curved double curved handle made of stainless steel, iron, surface treatment chrome, mirror, hole moment 66mm, 88mm, 100mm, 110mm, 120mm optional, suitable for modern minimalist style, fixed with M5 coarse tooth screws, suitable for equipment cabinet door.

- Manufacturer: HTAN

- Model: LS532

- Material: stainless steel, iron

- Surface treatment: chrome plated, mirror

- Application: equipment cabinet door

- Whether to support customisation: Yes

Buyer’s Guide and Frequently Asked Questions

Buying Guide

1.Material and Durability

The handle material must be corrosion-resistant and wear-resistant to ensure long-term use without deformation or damage.

2.Structure and Sealing Performance

The handle’s installation position and design should avoid interfering with the sealing performance of the cabinet.

3.Ease of Operation and Safety

The ergonomic design of the handle should align with operational habits, such as anti-slip texture and a comfortable grip, making it easier for personnel to quickly open and close the cabinet door.

4.Compatibility and Customization Requirements

Confirm whether the handle is compatible with the selected temperature and humidity-controlled chamber model.

FAQ (Frequently Asked Questions)

Q: What should be done if the rubber material of the handle deteriorates?

A: If the surface coating is worn, consider reapplying the coating or attaching a protective film.

Q: How to resolve handle jamming or difficulty in operation?

A: Clean the dust and debris from the telescopic track. If any parts are worn or deformed, replace the damaged components. For foldable handles, check the folding joints for any damage. If damaged, repair or replace them.

Q: What to do if the anti-slip performance of the handle decreases?

A: If the anti-slip texture is worn, consider reprocessing the anti-slip texture or applying an anti-slip sticker.