HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Introduction: Why ISO 9001 Matters for Welded Hinge Procurement

Global supply chains are increasingly interconnected. Quality awareness is rising. ISO 9001 certification is now a globally recognized quality management standard. According to ISO, over 1 million organizations in 189 countries use ISO 9001. Choosing an ISO 9001 certified welded hinge manufacturer means their processes are more standardized. Product quality is more consistent. Compared to uncertified manufacturers, certified ones have systematic quality assurance. They implement strict process monitoring. This significantly lowers error rates. It improves product uniformity. ISO 9001 certification involves audits by independent third parties. This provides credibility assurance for buyers. Essentially, choosing ISO 9001 certified manufacturers offers more reliable quality control. You get stricter process management. You also get better after-sales service. This minimizes procurement risks.

What is ISO 9001 Certification?

ISO 9001 is an international Quality Management System (QMS) standard. It is published by the International Organization for Standardization (ISO). The standard specifies requirements for establishing, implementing, maintaining, and continually improving a QMS. It applies to all types of organizations. To gain certification, a company must pass an audit by an independent certification body. This audit proves the company’s management system meets ISO requirements. Core requirements include top management commitment, a process approach, customer focus, risk-based thinking, and continual improvement.

Related certifications include ISO 14001 (Environmental Management), ISO 45001 (Occupational Health & Safety), and industry-specific systems. Examples are IATF 16949 for automotive and ISO 13485 for medical devices. These often build on the ISO 9001 framework. They add specific industry requirements. Overall, ISO 9001 is a universal, authoritative quality management framework. Third-party audits provide system-level assurance for product quality.

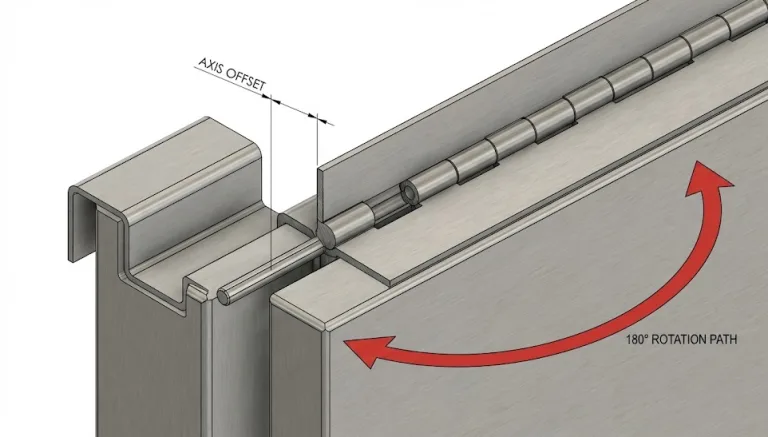

Welded Hinge Applications & Quality Requirements

Welded hinges are critical components. They connect parts in industrial machinery. They are widely used in industrial equipment, architectural doors/windows, and transportation. For example:

Warehouse Equipment Hinges

Used on racking and safety doors. Must handle heavy loads and frequent cycling. Static load capacity is often ≥8 kN. Lifespan is designed for ≥100,000 cycles.

Architectural Door/Window Hinges

Need high wind load resistance (1500–3500 Pa). Require long cycle life (≥100,000 cycles). Must resist environmental corrosion (pass 3000-hour salt spray test). Need specific ingress protection (e.g., IPX4).

Transportation Hinges

Used in automotive, rail, marine. Must remain reliable under vibration and shock.

Common failure modes include weld fatigue cracks (42% of failures), part wear (35%), and corrosion (23%) [1]. Causes include residual stress, cyclic loading, and insufficient lubrication. This demands manufacturers provide high-strength welding. Precision machining is essential. Excellent surface treatment is critical. For instance, architectural hinge hole position tolerance must be ≤ ±0.3 mm. Flatness must be ≤ 0.1 mm/300 mm. Different industries impose stringent quality and reliability demands on welded hinges.

Extra Guarantees from ISO 9001 Certified Welded Hinge Manufacturers

Material & Precision Guarantees

Certified manufacturers implement strict raw material traceability. The “Identification and Traceability” clause (ISO 9001) requires tracking from raw material to finished product. Every batch of steel, welding wire, etc., is documented. They control machining tolerances through documented procedures. This ensures stable part dimensions. For example, architectural hinge hole position tolerance ≤ ±0.3 mm is achievable. They use precision equipment and strict inspection. System management also ensures consistent surface treatment (e.g., galvanizing, coating). This prevents localized failures.

Controlled Production

ISO 9001 mandates multiple quality checks. These include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC). Certified manufacturers typically use PQC/IPQC/FQC systems. This prevents production deviations. They maintain batch traceability records. ISO requires “robust quality control processes”. This means all production stages are monitored. If problems occur, records allow quick root cause and batch identification.

Welding Process Stability

Weld quality is critical for hinges. ISO 9001 certified manufacturers strictly follow welding procedures. They employ qualified welders. They use calibrated equipment. Many also obtain ISO 3834 (welding quality system) certification. This further standardizes the welding process. Automated welding offers high repeatability. It produces consistent weld quality continuously. Manual welding is more variable. It depends on operator skill and fatigue. Certified manufacturers manage welder qualifications, parameters, and inspection records rigorously. This ensures reliable weld quality.

Product Consistency & Reliability

ISO 9001 emphasizes continual improvement and process stability. Certified manufacturers ensure consistent performance across batches. Test data shows: 304 stainless steel welded hinges achieve median fatigue life >105,000 cycles. Standard Q235 carbon steel hinges manage ~82,000 cycles. In corrosion resistance: After 1000 hours salt spray testing, carbon steel hinges rust completely. 304 stainless steel shows minimal rust spots. This data confirms certified products undergo rigorous design and testing. Their durability significantly exceeds non-certified products.

After-Sales & Technical Support

ISO 9001 requires focus on customer satisfaction. It mandates a problem resolution process. Certified companies usually provide better after-sales service. The standard includes a complaint handling mechanism. This guides efficient resolution of customer feedback. If hinge issues arise, certified manufacturers respond promptly. They follow system procedures to find the root cause. Corrective actions are implemented. They provide full technical documentation and installation guides. Warranties cover repairs or replacements. System-based management makes certified manufacturers accountable for quality. Buyers get stronger guarantees.

Certified vs. Non-Certified Manufacturers: A Comparison

Key differences exist:

Quality & Errors

Certified manufacturers pass system audits. Their error and defect rates are lower. Studies show ISO 9001 implementation can boost productivity by ~20%. Error rates can drop by ~50%. Certified suppliers have fewer quality disputes and returns. Their controlled processes ensure stability. Non-certified suppliers often have looser management. Inconsistent inspection leads to variable products. This causes rework and repairs.

Management

Certified companies use PDCA cycles and Total Quality Management (TQM). They have stronger problem prevention. Continual improvement is embedded.

Market Access

ISO 9001 is a global entry ticket. Many countries and large projects require it in tenders [2]. Examples include public works and multinational contracts [2]. Certified manufacturers win international orders more easily. Non-certified suppliers face barriers entering markets like the EU, US, or Japan. Trust is harder to establish.

Case Note: Public reports of specific welded hinge failures are rare. However, industry practice shows that using suppliers without proper quality management in critical projects can lead to severe consequences. Safety hazards or project delays are possible risks. For major projects or export orders, choosing ISO 9001 certified manufacturers minimizes risk.

How to Identify Genuine ISO 9001 Certified Manufacturers

Verify authenticity carefully:

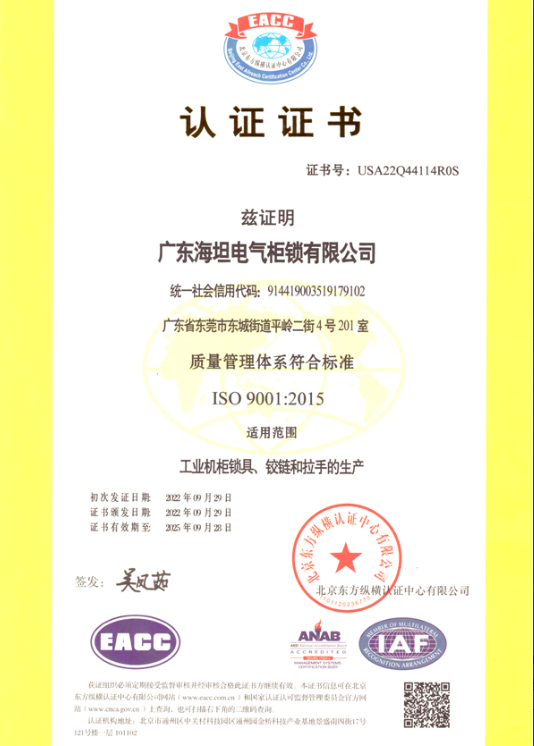

Check the Certificate

Look for the certification body’s logo. A valid certificate displays the IAF (International Accreditation Forum) mark. It should also show the national accreditation body’s mark (e.g., CNAS for China). In China, the issuing body must be registered with CNCA (Certification and Accreditation Administration).

Verify Online

Use the certificate number. Check the certification body’s official website. Alternatively, use the national accreditation body’s database. In China, use the CNCA unified query system (cx.cnca.cn). Search by certificate number or company name. Certificates not registered with CNCA are invalid. Be cautious if a certificate appears on the certifier’s site but not the national database.

Check Validity

ISO 9001 certificates are valid for three years. Annual surveillance audits are mandatory. Certificates expire if not renewed or if audits fail. Verifying validity prevents buying based on fake or expired certificates.

When to Prioritize ISO 9001 Certified Welded Hinge Suppliers

Prioritize certified manufacturers in these situations:

High-Reliability Projects

Large engineering projects demand extreme hinge reliability. Certified suppliers offer greater security.

Export/International Tenders

Orders for markets like the EU often mandate ISO 9001. Certified suppliers meet these buyer requirements easily.

Demanding Applications

Use certified suppliers for hinges under high loads or frequent cycling. Examples include heavy-duty warehouse doors or automated storage systems. These applications need long life (e.g., ≥8 kN load, ≥100,000 cycles). Highly stable production processes are essential.

Safety-Critical Industries

Always choose certified suppliers for aerospace, automotive, medical devices, or rail. Their quality systems align with strict regulations. Generally, choose ISO 9001 certified suppliers for high-risk or mission-critical projects.

FAQ

Who issues ISO 9001 certification?

Accredited third-party Certification Bodies (CBs) issue certificates. Examples include TÜV (Germany), SGS (Switzerland), BV (France), and BSI (UK). These CBs are authorized by national or international bodies (e.g., CNAS, UKAS).

What’s the advantage of ISO 9001 certified welded hinges?

Certified manufacturers have robust QMS. Their production is controlled. Product consistency is high. ISO 9001 emphasizes standardization and continual improvement. This enables them to “consistently provide products meeting customer and regulatory requirements.” Benefits include traceable materials, multi-stage inspections (PQC/IPQC/FQC), and complete quality records. Result: Certified hinges offer superior durability, dimensional accuracy, and weld quality. Non-certified products vary more.

When should I require ISO 9001 certification?

Require certification for high-risk projects or extreme environments. Examples: high-strength applications, ultra-low temperatures (e.g., -40°C), or high-cycle demands (≥100,000 cycles). Also require it for critical projects where delays or failures are unacceptable. Certification reduces quality incident risk.

Where is ISO 9001 certification mandatory?

Certification is often essential in highly regulated, safety-critical sectors. Examples: Aerospace, Rail, Automotive, Medical Devices. Industry-specific standards (like AS9100, IATF 16949, ISO 13485) are usually required. These are based on ISO 9001. Prioritize certified suppliers for public safety or strict regulatory compliance.

Why does ISO 9001 reduce procurement risk?

ISO 9001 requires a complete QMS. This includes risk control, process monitoring, and continual improvement. System assurance leads to stable quality and fewer defects. This reduces rework and safety issues. Certified suppliers undergo regular surveillance audits. Non-conformities must be fixed. This ensures reliable supply. As ISO states, certification helps organizations “consistently provide products… that meet customer and applicable statutory/regulatory requirements” and “enhance customer satisfaction.”

How do I verify a supplier’s ISO 9001 certification?

First, check their certificate. Look for the certificate number and CB details. Valid certificates show the CB accreditation number and IAF marks. Second, verify online:

- On the Certification Body’s official website.

- Using the national accreditation body’s database (e.g., CNCA in China: cx.cnca.cn). Enter the certificate number or company name.

Contact the CB directly if unsure. Be wary of certificates not found on official platforms.

Procurement Advice & Summary

Choosing ISO 9001 certified welded hinge manufacturers significantly lowers procurement risk. Their system management and continual improvement deliver precise, durable, and consistent products. This drastically reduces rework, returns, and delays. When procuring, consider quality certification alongside price, lead time, and technical capability. For large projects or exports, include quality agreements. Specify compensation clauses for non-conformance. This strengthens supply guarantees. Prioritizing ISO 9001 certified suppliers provides reliable quality and long-term technical support. It meets modern supply chains’ high standards for quality and safety.