HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Recent industrial hardware design projects demonstrate a clear trend: the design of equipment cases is undergoing a transformation from ‘bulky and single-function’ to ‘compact and modular

In the past, engineers often considered handles only at the final stage of design. They typically selected standard Fixed U-handles. However, in modern logistics and precision operation environments, I find that this simple choice is becoming a product weakness.

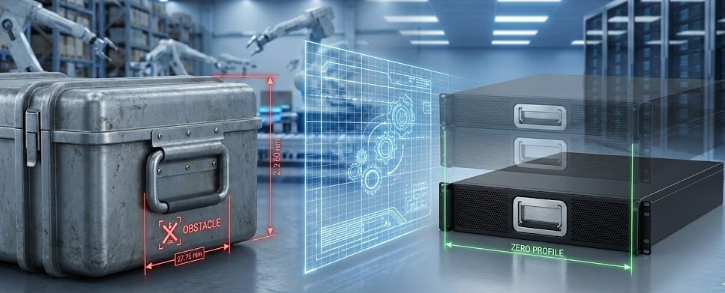

Fixed handles expose serious limitations during transport, stacking, and operation in narrow spaces. They occupy extra volume and are highly susceptible to damage from impacts.

As an industry consultant focused on mechanical structures, I believe the Foldable Handle is no longer just a simple accessory. It is a key component for resolving contradictions in modern industrial design. Through its unique “Zero Profile” design and high load-bearing capacity, it has become a standard configuration for precision instrument cases, medical equipment, and military chassis.

In this article, I will analyze the technical logic behind this shift based on actual engineering data and international standards.

Core Drivers: Space Optimization and Logistics Efficiency

In server rooms or automated warehouses, every millimeter of space is directly linked to cost. Based on my project experience, space optimization is the primary reason engineers abandon fixed handles.

Data Advantages of Flush Design

The core advantage of a foldable handle lies in its form when idle.

- Fixed Handle Data: Standard industrial U-handles typically protrude 30mm to 50mm from the case surface.

- Foldable Handle Data: The foldable models we recommend typically control protrusion height to within 15mm in the stowed state. Some recessed designs can even achieve 0mm (completely flush).

This means that in container shipping involving multiple devices, using foldable handles can significantly reduce the overall packaging volume.

Stacking and Rack Integration

For clients designing Rack-mounted Servers, I always emphasize referencing the EIA-310-D standard (19-inch rack standard).

- The Problem: Protruding fixed handles often block equipment from being pushed into the cabinet or prevent the cabinet door from closing completely.

- The Solution: The folding design eliminates permanent protrusions. This allows equipment to pass smoothly through standard-sized channels and allows front and rear doors to close completely, ensuring the internal cooling airflow of the cabinet is undisturbed.

Reducing Logistics Breakage Rates

According to my analysis of client return data, much of the damage to equipment on logistics conveyor belts is caused by protruding fixed handles getting snagged or snapped off.

Foldable handles reduce the complexity of the external profile. During Palletizing, the flat surface allows cases to be arranged tightly. This reduces the risk of packaging damage caused by uneven force distribution.

Safety and Ergonomics Considerations

Beyond space issues, operator safety is another key focus in my selection recommendations. Here, we need to reference OSHA 1910 (Occupational Safety and Health Administration standards for walking-working surfaces) and MIL-STD-1472 (Human Engineering Design Criteria).

Eliminating Collision Hazards

In narrow factory aisles or mobile medical stations, personnel movement is frequent.

- The Risk: Protruding fixed handles act like potential hooks. They can easily snag an operator’s clothing or cause physical impact injuries during rapid movement.

- The Improvement: Foldable handles sit tight against the case when not in use. This completely eliminates the hazard, complying with EHS (Environment, Health, and Safety) management requirements in industrial environments.

The Necessity of Spring-Loaded Return

When recommending a BOM (Bill of Materials), I usually mandate that clients select models with built-in torsion springs.

- Technical Analysis: This structure contains a pre-tensioned torsion spring.

- Function Implementation: When the operator releases the handle, it automatically snaps back to fit against the case recess.

- Value: This function prevents the handle from swinging in an uncontrolled state. In vibration environments (such as vehicle transport), it avoids continuous metal impact noise and prevents the handle from accidentally deploying and causing snags.

Grip Comfort and Insulation Design

For equipment weighing over 15kg, grip pressure is a parameter that must be calculated.

- Design Recommendation: I recommend adding a Rubber Sleeve or dip coating to stainless steel handles.

- Standard Reference: According to ISO 13732-1 (temperatures of touchable surfaces), bare metal can cause burns or frostbite in extreme temperatures.

- Practical Effect: The rubber sleeve not only provides necessary insulation protection but also increases the friction coefficient. This allows operators to grip securely even when wearing gloves.

Structural Strength and Durability Testing

Many engineers worry: Does adding moving joints mean decreased strength? According to our laboratory test data, as long as the selection is correct, the strength of foldable handles can fully meet heavy-duty equipment requirements.

90-Degree Stop Design

High-quality foldable handles do not just have “open” and “closed” states.

- Structural Feature: These handles are designed with an internal mechanical stop that limits the opening angle to a maximum of 90 degrees.

- Mechanical Principle: This ensures that when lifting heavy objects, the handle remains perpendicular to the case surface. The pulling force is transmitted directly along the axis. This avoids generating extra Shear Force on the mounting screws, maximizing force transmission efficiency.

Load Data Analysis

We conducted Static Load Tests on handles of different diameters in our testing laboratory.

- Test Object: 10mm diameter solid stainless steel foldable handle.

- Test Result: This specification can typically withstand a continuous pull of over 1000N (approx. 100kg) without permanent deformation.

- Comparison: This is far higher than the load limit of ordinary plastic handles (usually 30kg-50kg).

- Standard Reference: We recommend requesting test reports based on IEC 60068-2-47 (mounting component strength testing) from suppliers during procurement.

Vibration Resistance Performance

For military or vehicle-mounted equipment cases, vibration resistance is a core indicator.

- Test Standard: Products must pass MIL-STD-810G Method 514.6 (Vibration Test).

- Performance: Foldable handles with damping or spring loading do not collide with the case during random vibration. This ensures the acoustic concealment and structural integrity of the equipment.

Material Science: How to Select the Right Material

Material selection directly determines the service life and environmental adaptability of the handle. I provide the following selection suggestions based on ASTM standards:

304 vs. 316 Stainless Steel

This is the preferred material for high-end industrial equipment.

- 304 Stainless Steel: Suitable for most outdoor equipment and food processing machinery. It has good rust resistance.

- 316 Stainless Steel: Contains Molybdenum. I strongly recommend using 316 material in marine environments, chemical plants, or high salt spray environments.

- Test Standard: Must pass the ASTM B117 Neutral Salt Spray Test. 304 typically needs to pass 96 hours, whereas 316 needs to pass over 500 hours without red rust.

Aluminum Alloy

- Applicable Scenarios: Aviation cases, portable drone ground stations, photography equipment cases.

- Characteristics: Density is only 1/3 of steel. Through Anodizing, various appearances like black or silver can be achieved, with high surface hardness.

- Limitation: Tensile strength is slightly lower than steel. It is not recommended for equipment where a single hand lifts more than 50kg.

Chrome Plated Steel

- Applicable Scenarios: Indoor dry environment server chassis, audio equipment.

- Characteristics: Cost-effective with a bright metallic luster.

- Warning: In high-humidity environments, the plating will rust easily once scratched. I do not recommend this material for outdoor projects.

Typical Application Case Studies

To illustrate the practical application of the above theories, I have compiled three typical client cases.

Ambulance Response Case

- Challenge: Space inside the ambulance is extremely limited, and equipment must be stacked. The equipment also requires frequent cleaning with disinfectants.

- Selection: 304 Stainless Steel Foldable Handle with Spring Return.

- Result: Achieved multi-layer stacking, saving approximately 15% of storage cabinet space. The stainless steel material withstood daily alcohol wiping without corrosion.

Military Rugged Case

- Challenge: Equipment must pass airdrop tests and withstand severe impacts.

- Selection: Recessed Heavy-Duty Foldable Handle with 90-degree Stop.

- Result: The recessed design protected the handle from direct impact. In the MIL-STD-810G drop test, the handle structure remained intact and caused no secondary damage to the case.

Portable Water Quality Tester

- Challenge: Environmental engineers need to carry equipment on foot into the field; hands are prone to sweating.

- Selection: Aluminum Alloy Foldable Handle with Thickened Rubber Grip.

- Result: The rubber grip provided excellent anti-slip performance, reducing hand fatigue during long-distance carrying.

Conclusion and Actionable Advice

To summarize my view: The switch from fixed handles to foldable handles by engineers is not purely for aesthetics. It is a rational engineering decision based on Space Efficiency, Operational Safety, and Total Lifecycle Costs.

My advice for design teams is as follows:

Early Involvement: Reserve the installation position for foldable handles during the initial phase of establishing the BOM. Changing cutout dimensions later increases tooling costs.

Focus on Return: Unless costs are extremely sensitive, prioritize models with spring-return functionality. This significantly enhances the quality experience for the end user.

Verify Standards: When purchasing, ensure you request load test reports and salt spray test reports specific to that model. Do not rely solely on general datasheets.

FAQ

Q: What is the maximum load capacity of a foldable handle?

A: The load capacity of an industrial-grade foldable handle depends on the material (stainless steel or aluminum) and the rod diameter. Generally, a 10mm diameter stainless steel foldable handle can withstand a static pull of over 100kg (approx. 980N). For heavy-duty applications, please refer to supplier test data based on IEC 60068-2-47 standards.

Q: What are the benefits of a spring-loaded foldable handle?

A: The spring-return function ensures the handle automatically snaps back against the case immediately after release. This prevents noise generation due to vibration during transport and avoids accidental protrusion that could snag personnel or damage equipment, aligning with OSHA safety guidelines.

Q: Which material should be selected for outdoor equipment case handles?

A: For outdoor environments, I strongly recommend selecting 304 or 316 grade stainless steel. They have extremely high corrosion resistance and can withstand rain, salt spray, and temperature changes. If in a marine or coastal environment, 316 stainless steel must be used to comply with ASTM B117 salt spray test requirements.

Q: Does installing a foldable handle require welding or screw fixing?

A: Both methods are viable, depending on the case material and strength requirements. Heavy-duty equipment or sealed cases often use welding or back-nut fixing to achieve maximum strength. Light-duty equipment or panels requiring maintenance can use front screw installation. Note that welding installation requires subsequent Passivation treatment of the stainless steel to prevent rust.

-768x768.png)