HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Specifying Heavy-Duty Industrial Hinges requires balancing cost efficiency with engineering performance. While Purchasing Managers and Engineers may have different priorities, their ultimate goal is aligned: ensuring reliable, maintenance-free operation for critical industrial equipment.

This guide provides a professional engineering analysis of why industrial hinges require bushings or bearings. We break down the tribology behind the hardware and offer selection advice compliant with EN 1935 and ANSI/BHMA standards.

Common Failure Modes: The Risks of Metal-on-Metal Friction

In traditional hinge designs lacking bushings or bearings, the hinge pin makes direct contact with the knuckle bore (Metal-on-Metal). Over long-term operation, this results in irreversible failure modes:

Friction Spikes and Binding

A smooth, new hinge may rotate well initially, but as cycle counts increase, surface roughness and deformation cause the coefficient of sliding friction to spike.

- Consequence: The torque required to open the door increases drastically, resulting in poor tactile feel (haptics) and even “binding” due to heat generation and lubricant loss.

Wear-Induced Sagging (Door Misalignment)

Direct metal friction generates abrasive particles, gradually wearing down the pin and bore diameter, increasing the fit clearance.

- Consequence: When hinge play exceeds tolerance, the door experiences sagging, causing latches to misalign or seals to fail.

Galling (Cold Welding) and Noise

Steel-on-steel friction is highly prone to adhesive wear, known as galling.

- Risk: Under high pressure or lack of lubrication, material combinations like Stainless Steel vs. Stainless Steel can suffer from microscopic cold welding, causing the hinge to seize or tear. This is often accompanied by screeching noise and metallic dust contamination.

Failure to Meet Cycle Life Standards

European standard EN 1935 requires heavy-duty door hinges to achieve at least 200,000 cycles (Grade 7), while the US ANSI/BHMA A156.1 standard demands up to millions of cycles.

- Conclusion: Hinges without friction-reducing designs struggle to approach these lifespans, leading to early field failure.

Core Engineering Value: Friction Management and Load Distribution

The integration of bushings and bearings essentially transforms chaotic, uncontrolled sliding friction into controlled engineering performance.

Reducing the Coefficient of Friction (CoF)

- Dry Friction (Steel-on-Steel): CoF $\approx$ 0.4 – 0.6

- Bronze Bushing (Lubricated): CoF $\approx$ 0.08 – 0.15

- Rolling Bearing: CoF $\approx$ 0.001 (One order of magnitude lower)

- Value: Significantly reduces breakaway torque for smoother operation.

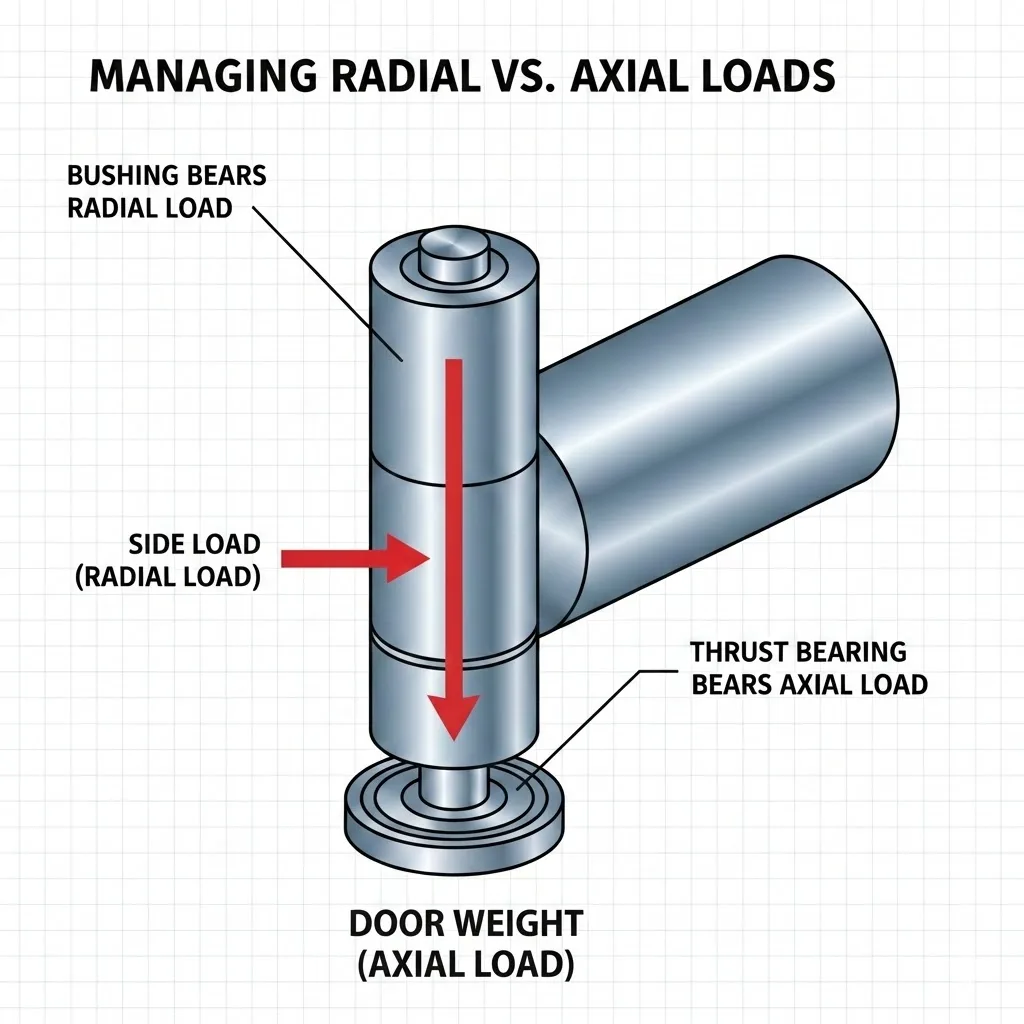

Managing Radial vs. Axial Loads

- High-Performance Bushings handle extreme Radial Loads (door weight) by distributing stress across a large contact area.

- Thrust Bearings are specifically engineered to absorb Axial Loads (vertical force), preventing wear on the knuckle faces.

The “Sacrificial Wear Component” for TCO

Bushings act as replaceable “wear parts,” protecting the expensive hinge pin and leaf structure. Maintenance only requires replacing the low-cost bushing, aligning with Total Cost of Ownership (TCO) optimization principles.

What are Bushings (Plain Bearings)?

A bushing is a cylindrical sleeve (technically a Plain Bearing) that relies on the material’s inherent low-friction properties to facilitate movement.

Common Material Types

- Metal Bushings (Bronze/Brass): Such as SAE 841 Oil-Impregnated Bronze. Soft and self-lubricating, effective at preventing steel-on-steel galling.

- Self-Lubricating Composite Bushings: Steel backing + Sintered layer + PTFE/POM plastic layer (ISO 3547 compliant). Combines metal strength with plastic’s low friction, ideal for maintenance-free scenarios.

Pros and Cons Analysis

- Pros: Cost-effective, simple structure, high impact resistance (due to surface contact), and contaminant tolerance (dust embeds into soft metal).

- Limitations: Significant heat generation at high speeds; exhibits “stick-slip” (static friction); clearance gradually increases with wear.

What are Bearings (Rolling Element)?

When referring to “bearings” in hinges, we typically mean Rolling Element Bearings, which convert sliding friction into rolling friction using balls or needles.

Common Configuration Types

- Ball Bearings: Ideal for precision, smooth haptics (e.g., precision instrument doors).

- Needle Bearings: Long contact area, suitable for ultra-heavy doors (e.g., mining machinery hatches).

- Thrust Bearings: Configured at the top/bottom of the knuckle to absorb vertical gravity loads.

Pros and Cons Analysis

- Pros:

- Ultra-Low Friction: Almost zero startup resistance.

- Extended Cycle Life: Can easily achieve millions of cycles (calculated via ISO 281 L10 formulas).

- High Precision: Maintains strict concentricity, preventing door shift.

- Limitations:

- Higher cost (requires precision machining).

- Environmental Sensitivity: Dust and water washdown can damage rolling elements; requires robust sealing design.

Selection Decision: Bushing vs. Bearing Technical Comparison Matrix

The following table summarizes key engineering parameters to assist procurement and engineering teams in decision-making:

| Key Parameter | Bushing Solution (Plain Bearing) | Bearing Solution (Rolling Element) |

| Ideal Load Type | Static Heavy Load (Radial) | Dynamic Composite Load (Radial + Axial) |

| Impact Resistance | Strong (Surface contact disperses stress) | Weak (Point contact prone to Brinelling) |

| Tactile Feel (Haptics) | Some damping, higher startup torque | Excellent, light and smooth |

| Cycle Life | Material dependent (Usually <500k) | Ultra-Long (Can exceed 1M+ cycles) |

| Environmental Suitability | High (Dust, Heat, Washdown resistant) | Low (Requires Sealing, sensitive to dust) |

| Maintenance Strategy | Flexible (Oil or Maintenance-Free) | Typically Sealed for Life |

| Cost Efficiency (TCO) | Low initial cost, ideal for volume | High initial cost, reduces downtime |

Selection Advice:

- Choose Bushings: If the environment is harsh (dust, washdown), the door is heavy but opened infrequently, or budget is a constraint.

- Choose Bearings: If the application requires feather-light operation, high-frequency cycling (automation), or zero-clearance precision positioning.

Critical Lifecycle Factors: Material Pairing, Surface Treatment, and Lubrication

Choosing between a bushing or a bearing is not enough; the following “Hidden Factors” determine the ultimate service life:

Material Pairing and Anti-Galling

- Avoid Like Materials: Stainless Pin vs. Stainless Bushing is a recipe for failure. Use the “Hard vs. Soft” principle (e.g., Hardened Steel Pin + Bronze Bushing).

- Sacrificial Anodes: In corrosive environments, use plating or a softer bushing as a sacrificial element to protect the main structure.

Surface Treatment and Hardening

- Hardening: Carburizing or QPQ treatment on steel pins (Hardness >HRC60) significantly reduces pin wear.

- Anti-Friction Coatings: Apply Molybdenum Disulfide or AS4783 compliant coatings for dry lubrication protection.

- Corrosion Resistance: Verify zinc plating or passivation via ASTM B117 Salt Spray Tests.

Lubrication Strategy (Tribology)

- Grease: Select heat-resistant grease based on NLGI Grade.

- Boundary Lubrication: For low-frequency, high-load startups (Boundary Lubrication state), PTFE self-lubricating bushings often perform better than greased bearings, avoiding “stick-slip” phenomena.

Vertical Application Analysis: Real-World Scenarios

- Data Center Server Racks:

- Requirement: High volume, cost-sensitive, indoor controlled environment.

- Solution: Self-Lubricating Bushings. Provide appropriate damping to prevent door drift.

- Heavy Machinery (Excavators/Mining Trucks):

- Requirement: Extreme load, high vibration, mud/sand exposure.

- Solution: Hardened Pin + Needle Bearing + Seals. Double-row needles handle gravity; seals prevent mud ingress.

- Food & Pharma Equipment:

- Requirement: High-pressure washdown, FDA compliance.

- Solution: Stainless Steel Body + Food-Grade Polymer Bushing. Hygienic design with no hidden crevices, resistant to chemical cleaning.

- Automation Safety Gates:

- Requirement: Thousands of cycles daily, ultra-low resistance.

- Solution: Precision Ball Bearings. Ensures pneumatic actuators operate without lag.

Procurement Specification Checklist (RFQ Guide)

To reduce communication costs, clearly define the following parameters in your Request for Quotation (RFQ):

- Load Parameters: Door Weight (kg), Center of Gravity distance, Max Torque (N·m).

- Life Expectancy: Expected cycle count (e.g., 200,000 cycles per EN 1935 Grade 7).

- Operating Environment: Temperature range, IP Rating requirements, exposure to corrosive agents.

- Maintainability: Do you require “Field Replaceable Bushings” or “Sealed Maintenance-Free”?

- Compliance: RoHS, REACH, FDA, UL Fire Ratings, etc.

FAQ

Q: Do industrial hinges always require bearings?

A: No. For light-load, low-frequency applications (like toolboxes), quality bushings or even unlined hinges are sufficient. Bearings only offer ROI in high-frequency, heavy-load, or high-precision scenarios.

Q: Are self-lubricating bushings truly “Maintenance-Free”?

A: Yes, they require no greasing within their rated life. However, “Maintenance-Free” does not mean “Infinite Life.” Under high loads, wear gap checks are still recommended.

Q: Which solution is better for dusty environments?

A: Bushings are generally better. Dust can seize a standard bearing, whereas bushings allow dust to embed into the soft material. If bearings are mandatory, ensure you specify models with Double Rubber Seals (2RS).

-768x768-1.png)