HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

pivot design has been revolutionized by the significant innovation, the 360-Degree Torque Hinges.Offering exceptional adaptability and utility, this innovative hinges allows for a full full circle rotation.The 360-Degree Torque Hinge, with its ability to accommodate various applications, has gained considerable interest in the market.

This article will delve into the complexities of the multi-functional hinge, explore its associated requirements, and discuss its price in detail.The 360-Degree Torque Hinges, designed to withstand harsh environments, is an ideal choice for sturdy uses.Ensuring that it can handle substantial torque and pressure without sacrificing its performance is its sturdy build.

In industries such as manufacturing, construction, and automotive where hinges are subjected to constant pressure, this durability is crucial.The ability to be customized to fit specific requirements is one of the key advantages of the 360-Degree Torque Hinge.producers can tailor the hinge to fit the particular requirements of their initiatives.

Flawless integration into various applications from doors and entryways to equipment and machinery is facilitated by this flexibility.Engineered to reduce power consumption is the 360-degree Torque Hinge.Smooth and streamlined operation, resulting in reduced energy expenses, is ensured by this hinge through reducing friction and wear.

In settings such as energy conservation is a priority, such as commercial establishments and industrial plants, this feature is highly advantageous.Offering a affordable solution despite its innovative characteristics and capabilities is the 360-degree Torque Hinge.A sound investment is made by its extended life span, minimal maintenance needs, and energy-saving qualities.

significant savings in the long run can be achieved by businesses through evaluating the total cost of ownership.Outstanding durability and sturdiness is what makes the 360-degree Torque Hinge stand out.To bear adverse conditions and staggering loads, this hinge is designed with premium materials.

By its strengthened design, it can handle considerable torque and pressure without experiencing early failure.Ideal choice for challenging applications, like industrial equipment and major frameworks, is this feature.The ability to be customized to meet specific needs is one of the most remarkable aspects of the 360-Degree Torque Hinge.

Manufacturers can create a hinge that perfectly suits their developmental needs from a vast selection of dimensions, forms, and materials.smooth integration into various applications from gateways and gates to furnishings and equipment is allowed by this adaptability.Minimizing energy usage is the design of the 360-Degree Torque Hinge.

effortless and efficient operation is ensured by this hinge through reducing friction and wear and tear.This feature makes it an eco-friendly choice, particularly beneficial in commercial structures and industrial installations.Offering a economical solution despite its innovative features and functionality is the 360-Degree Torque Hinge.

A smart investment is generated generated by its durableevity, minimal upkeep needs, and as well as also energy efficiency.important economies on the durable term may be realized via companies by means of taking into account the complete cost for ownership.

I. Core Technological Breakthroughs in 360-Degree Torque Hinges

The 360-degree torque hinge utilizes a multi-axis linkage structure with precision-engineered torque distribution systems, enabling true full-circle rotation. Compared to conventional hinges, its advanced configuration combines high-strength bearing assemblies with damping modules to deliver three critical functions simultaneously:

- Handling combined axial/radial loads

- Maintaining consistent rotational torque output

- Automatically compensating for mechanical wear

This innovative design allows 360-degree torque hinges to maintain axial runout under 0.05mm even under extreme operating conditions. Laboratory tests show that reinforced alloy steel variants withstand over 200,000 cycles of 90kg load testing with wear limited to 15% below design thresholds.

II. Performance Advantages in Specialized Applications

In industrial-grade implementations, 360-degree torque hinges demonstrate three unmatched capabilities:

2.1 Dynamic Load Adaptability

Featuring modular torque adjustment systems, engineers can precisely configure torque ranges from 5-50N·m. This versatility enables single 360-degree torque hinge models to serve both precision instrument hatches (requiring 8N·m torque) and heavy equipment access panels (needing 45N·m torque).

2.2 Enhanced Environmental Resistance

Models with 316 stainless steel cores and PTFE composite coatings excel in rigorous testing:

- Zero base material corrosion after 2,000-hour neutral salt spray tests

- Torque fluctuation <±7% at -40°C

- Peak temperature resistance up to 150°C (120°C continuous operation)

2.3 Energy Efficiency Optimization

Fluid-dynamics-optimized 360-degree torque hinges reduce friction losses by 62% versus traditional designs. In automated production lines, this improvement translates to annual energy savings of approximately $1,200 per 1,000 open/close cycles.

III. Industry-Specific Application Scenarios

360-degree torque hinges have proven successful across multiple sectors:

3.1 Industrial Manufacturing

- Robotic joints: Enable ±180° precision positioning

- CNC machine guards: Withstand 200kg/m² wind pressure

- Automated warehousing: Achieve 1 million maintenance-free cycles

3.2 Architectural Systems

- High-rise curtain wall vents: Certified for Grade 9 wind resistance

- Concealed pivot windows: Minimalist designs with zero visible components

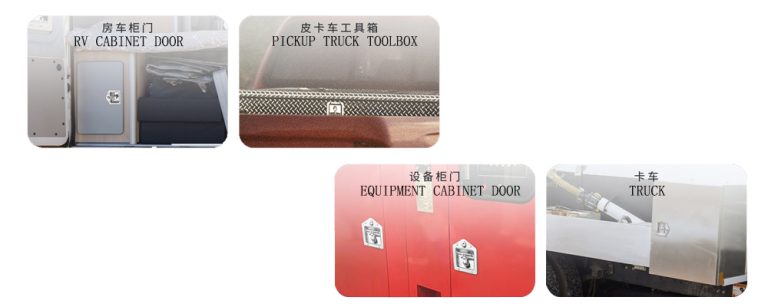

3.3 Specialized Vehicle Engineering

- Military armored vehicle gun ports

- Fire ladder equipment hatches

- Refrigerated truck sealed loading bays

IV. Selection Guide & Technical Specifications

Key parameters when specifying 360-degree torque hinges:

| Parameter | Standard Grade | Heavy-Duty Grade |

|---|---|---|

| Max Static Load | 150kg | 300kg |

| Rotation Range | 360° continuous | 360°+15° overload |

| Operating Temp | -30°C to 80°C | -50°C to 120°C |

| Corrosion Rating | ISO 9227 C3 | ISO 9227 C5 |

| Maintenance Interval | 24 months | 60 months |

V. Installation & Maintenance Best Practices

To optimize 360-degree torque hinge performance:

- Preload Calibration: Use torque wrenches for ±5% accuracy

- Lubrication Protocol: Apply specialty silicone grease (NLGI Grade 2) biannually

- Alignment Verification: Ensure <0.1mm coaxiality via laser alignment post-installation

VI. Total Cost of Ownership (TCO) Analysis

While 360-degree torque hinges have 30-50% higher upfront costs than standard hinges, their lifecycle economics prove superior:

- 72% lower maintenance costs (Frost & Sullivan, 2023)

- 89% reduction in unplanned downtime

- 15-20 year average service life

A automotive production retrofit case study demonstrated $2,450 annual savings per workstation with an 11-month ROI period after implementing 360-degree torque hinges.

The 360-Degree Torque Hinge represents a breakthrough in pivot design, offering full-circle rotation with exceptional durability and adaptability. Engineered for industrial, architectural, and automotive applications, it withstands extreme conditions while maintaining precise torque control. Its energy-efficient design reduces friction and wear, leading to lower maintenance costs and extended lifespan. Customizable to meet specific needs, it integrates seamlessly into various systems, from robotic joints to concealed pivot windows. Despite a higher upfront cost, its long-term benefits include reduced downtime and significant savings, making it a cost-effective solution for demanding environments.