HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In the realm of environmental testing, the term Environmental Test Handles refers to the numerous tools and instruments intended to handles and manage equipment that is used to evaluate the performance and sturdiness of products under various environmental conditions. These handles are vital components in the testing process, ensuring that the equipment functions effectively and safely. The need for superior quality, reliable handles has been growing, as businesses continue to emphasize the importance of strict testing for product quality verification.

Requirements:

1. Durability

.png)

2. Easy Handling

3. Compatibility

4. Safety Standards

Article:

Durability

Environmental Test Handles are subjected to demanding conditions, and therefore, they must be made from superior quality materials that can endure harsh conditions. The handles should be corrosion-resistant, wear, and tear, ensuring that they remain operational even after long-term use. Durability not only extends the service life of the handles but also reduces the overall cost of upkeep and replacement.

Easy Handling

The primary purpose of Handles for Environmental Test gear is to facilitate for users to manipulate the gear. These handles should be designed with user satisfaction in mind, featuring designs that conform to the human body and ergonomicalal grips. Easy handling not only minimizes user tiredness but also enhances productivity and effectiveness in testing.

Compatibility

Handles for Environmental Test gear should be compatible with a diverse array of testing devices to suit different market requirements. This includes various types of test chambers, climate simulators, and other testing instruments. Compatibility ensures that the handles can be used in multiple settings, making them a adaptable accessory to any testing lab.

safety guidelines

Safety is a top priority in the testing industry, and Handles for Environmental Test gear must meet rigorous safety regulations. These handles should be designed to guard against operator harm, such as pinch of the fingers or electric stuns. Additionally, they should be made from insulating materials to avert incidents caused by electric currents.

In this article, we will delve deeper into each of these requirements and discuss the importance of selecting the right Environmental Testing Handles for your testing facility.

1. resilient construction

The durability of Environmental Testing Handles is crucial, as they are often exposed to severe conditions, such as intense temperatures, moisture, and chemical contact. superior materials, such as inox steel or strengthened plastic, are ideal for creating durable handles. These materials can withstand the time test and provide a dependable solution for your testing equipment.

2. easy manipulation

An easy-to-handle Environmental Test Equipment Handle can make a significant difference in the efficiency of your test procedure. ergonomical design, ergonomic grips, and lightweight design are essential factors to consider when selecting handles. By investing in accessible handles, you can improve user satisfaction and reduce the risk of fatigue-related accidents.

3. Compatibility

The compatibility of Environmental Test Equipment Handles is crucial for ensuring their usability with various test apparatus. When selecting handles, it’s important to take dimensions into account, mounting alternatives, and material suitability of your existing equipment. This will make sure that the handles integrate smoothly into your testing arrangement and improve overall effectiveness.

4. Safety Standards

Safety is always a highest concern when selecting Environmental Test Equipment Handles. make sure that the handles comply with industry norms, such as those set by the OSHA (OSHA) or the IEC (IEC). Investing in handles that comply with safety regulations can aid in preventing incidents and guard your workforce.

In conclusion, Environmental Test Equipment Handles have a vital function in the testing procedure. By centering on sturdiness, ease of handling, compatibility, and safety standards, you can make sure that your testing environment has the most appropriate tools for the job. With the right handles, you can heighten effectiveness, effectiveness, and safety in your testing activities.

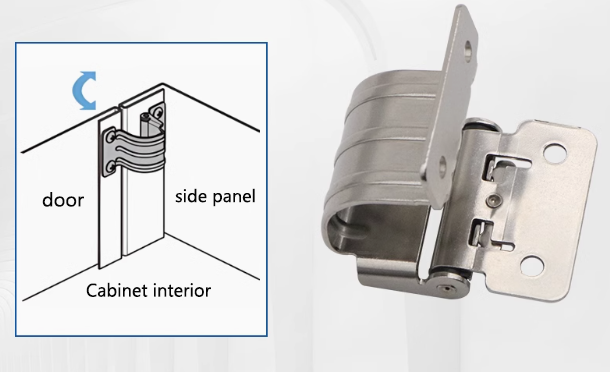

HTAN, founded in 2015, is a professional company specializing in the research, development, and manufacturing of industrial housing components. The company’s main products include torque hinges, handles, regular hinges, latches, and other cabinet door accessories.

Used in specialized vehicles and modified vehicles, heavy-duty truck container cabinets, rail transit equipment, communication and power equipment, medical devices, industrial automation machinery, ships, and a wide range of industrial equipment.

-768x768-1.png)