HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Figure 1. Real-world example of catastrophic hinge failure leading to cabinet door detachment and internal module damage.

In industrial hardware procurement, the heavy-duty hinge is a critical component. If a heavy-duty hinge fails, the consequences are often severe.

Consider this scenario: an 80kg (176 lbs) access door detaches from a piece of equipment. This results in damage to expensive electronic components and creates significant safety liabilities. In comparison, the initial purchase cost of the hinge itself is negligible.

This type of failure is usually not due to natural wear and tear, but rather non-conforming manufacturing quality. Many suppliers lower material and process standards to reduce costs.

This article analyzes 5 critical heavy-duty hinge defects that are responsible for early failure. We reference ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) standards to help you identify risks during the procurement phase.

Material Grade Discrepancies and Purity Issues

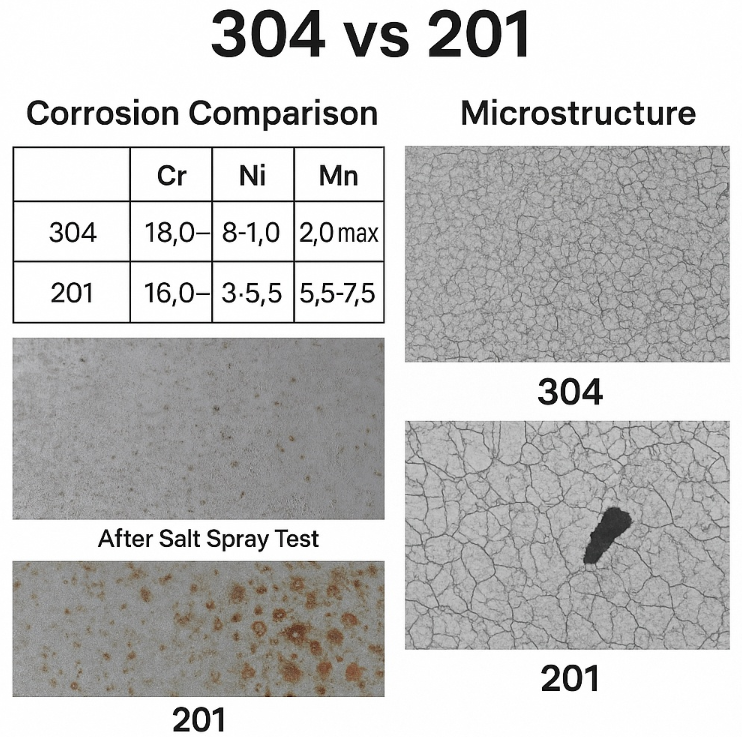

Many purchase contracts specify the use of SUS304 stainless steel. However, not all “stainless steel” possesses the same mechanical properties.

Root Cause: Recycled Scrap and Material Substitution

- Material Purity Issues: Substandard suppliers often use recycled scrap steel. This steel contains uncontrolled impurities and microscopic porosity. Under tensile load, these impurities act as stress concentration points, leading to brittle fracture of the metal.

- Grade Substitution: Suppliers may substitute 201 stainless steel for 304 stainless steel. The nickel content of 201 stainless steel is typically below 1.5%, whereas 304 stainless steel must contain between 8.0% and 10.5% nickel. In corrosive environments, 201 material oxidizes rapidly, leading to structural strength degradation.

Procurement Verification Strategy

Do not rely solely on verbal confirmation. Execute the following steps:

- Request Documentation: The supplier must provide a Material Test Report (MTR/Mill Certificate) for every shipment.

- Reference Standards: Ensure materials comply with ASTM A240 or ASTM A276.

- Incoming Quality Control (IQC): Use a handheld X-Ray Fluorescence (XRF) analyzer to verify Nickel (Ni) and Chromium (Cr) content. If the Nickel content is below standard, the batch is non-conforming.

Lack of Heat Treatment on Pins

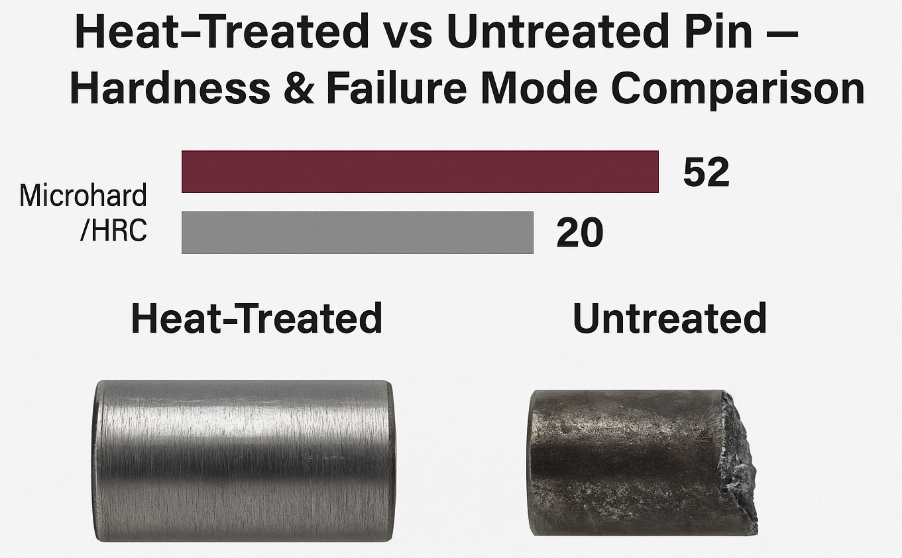

In heavy-duty hinge design, the pin bears the primary shear load. The hardness of the pin directly determines the service life of the hinge.

Root Cause: Low Hardness Leading to Wear and Shear Failure

Premium heavy-duty hinge pins require heat treatment (such as quenching) to achieve a surface hardness of HRC 50-55.

If a supplier omits the heat treatment process and uses ordinary cold-drawn steel bars, the pin hardness will be insufficient.

- Consequence 1: Rapid wear of the pin, causing a reduction in diameter.

- Consequence 2: Door sagging and alignment deviation.

- Consequence 3: Under high loads, soft pins will bend or suffer immediate shear failure.

Procurement Verification Strategy

During the technical drawing review phase, confirm the following details:

- Process Inquiry: Ask the supplier: “Are the pins heat-treated? What is the surface hardness specification?”

- Design Check: Confirm if the hinge design includes bushings. Brass or oil-impregnated bushings reduce direct metal-to-metal friction.

- Reference Standards: Refer to ISO 683-17 regarding technical delivery conditions for heat-treated steels.

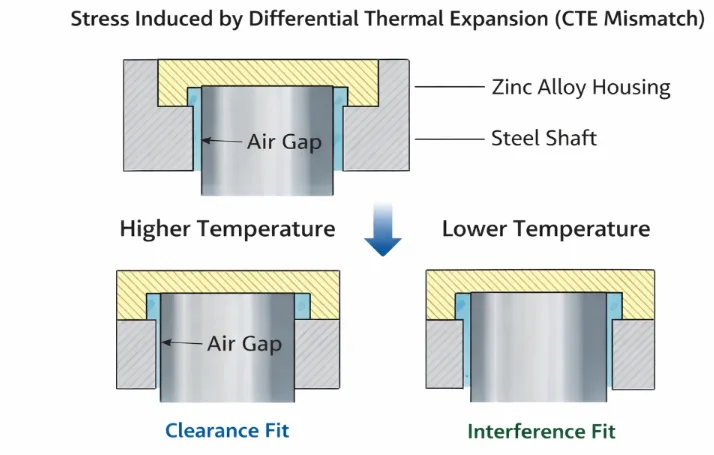

Static Rated Load vs. Dynamic Application Stress

The “Maximum Load” on a specification sheet typically refers to Static Load. However, real-world applications usually involve Dynamic Load.

Insufficient Safety Factor

When a door is slammed shut, impacted by wind, or vibrated during transport, the force exerted on the hinge increases significantly.

- Physical Fact: A 20kg door can generate 80kg of impact force during vehicle bumps (calculated based on 4G acceleration).

- Selection Error: If a hinge is selected based solely on static weight without a sufficient safety factor, the hinge will fracture under impact.

Procurement Verification Strategy

When selecting a model, you must calculate the Safety Factor.

- Static Application (Indoor/Stationary): Recommended Safety Factor is 1.5x.

- Dynamic Application (Outdoor/Vehicle/Frequent Use): Recommended Safety Factor is 3.0x or higher.

- Actionable Advice: Provide your application scenario data to the supplier. Request that they recommend models based on ASCE 7-16 (Wind Load Standards) or similar engineering standards.

Hydrogen Embrittlement from Plating Processes

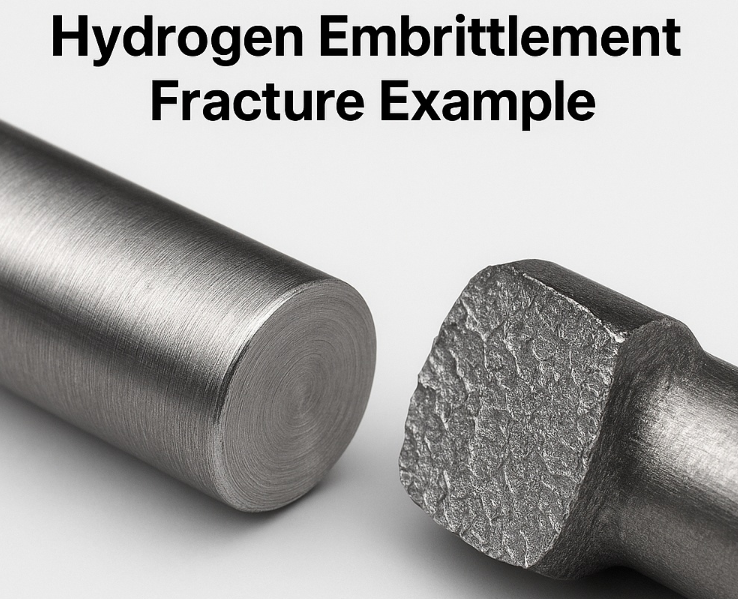

If a carbon steel hinge fractures suddenly shortly after installation, and the fracture surface is flat with no deformation, the cause is usually Hydrogen Embrittlement.

Root Cause: Failure to Remove Residual Hydrogen

During acid pickling and electroplating, hydrogen atoms penetrate the steel. If the steel is not baked immediately after plating, these hydrogen atoms cause extreme internal pressure. This makes the steel highly brittle.

Additionally, if the plating thickness is insufficient (below 5-8 microns), the hinge will fail basic corrosion resistance tests.

Procurement Verification Strategy

For surface-treated carbon steel hinges, process control is mandatory.

- Critical Question: Ask the supplier: “Is de-embrittlement baking performed after plating? What are the specific temperature and duration?” (Standard practice is typically 200°C for 4 hours).

- Test Requirements: Request an ASTM B117 Salt Spray Test Report from a third-party laboratory.

- Reference Standards: Refer to ASTM F519 regarding mechanical hydrogen embrittlement evaluation during plating processes.

Unverified Cycle Life Claims

Suppliers may claim a product life of “50,000 cycles.” However, without test data support, this figure is meaningless.

Lack of Fatigue Testing

Overlooking fatigue testing leads to one of the most common hidden heavy-duty hinge defects: structural failure under cyclic loading and significant time. Many small factories do not possess testing laboratories. They label life parameters based on guesswork.

In actual use, metal fatigue causes the hinge to fracture before reaching 10% of the claimed life.

Procurement Verification Strategy

Demand objective evidence.

- Lab Audit: During factory audits, check if their laboratory has a running fatigue testing machine.

- Third-Party Certification: For critical projects, require test reports from SGS or TÜV.

- Reference Standards: European standard EN 1935 clearly defines durability grades for hinges (e.g., Grade 12 or Grade 13).

Implementing Value-Based Procurement

Reducing unit purchase price is important, but not at the expense of reliability. If a substandard hinge causes a field failure, the repair cost will far exceed the procurement savings.

To identify and eliminate these heavy-duty hinge defects before they reach your assembly line, procurement managers should focus on:

- Verifying material chemical composition.

- Confirming pin heat treatment hardness.

- Calculating safety factors based on dynamic loads.

- Strictly controlling plating and de-embrittlement processes.

- Demanding real life-cycle test data.

Next Steps

If your equipment operates in harsh environments, we recommend an immediate review of your current hinge specifications.

We offer free technical consultation. Please contact our engineering team, and we will help you analyze your current BOM (Bill of Materials) and provide a “Heavy-Duty Hinge Quality Inspection Checklist (PDF)” to assist you in refining your incoming quality standards.

Frequently Asked Questions

Q1: How can I quickly tell the difference between 304 and 201 stainless steel without a lab? A: The most reliable field method is using a handheld PMI (Positive Material Identification) gun or XRF analyzer. It gives an immediate reading of Nickel and Chromium levels. Magnetic testing is unreliable because cold-working can make 304 slightly magnetic.

Q2: What is the standard salt spray test requirement for outdoor hinges? A: For standard outdoor environments, we recommend a minimum of 96 hours in a Neutral Salt Spray (NSS) test according to ASTM B117. For coastal or marine environments, specify SUS316 stainless steel or a finish rated for 500+ hours.

Q3: Why do my hinges seize up even if they aren’t rusty? A: This is often due to “galling” (cold welding) between the pin and the knuckle. This happens when similar metals rub against each other under high load without lubrication. Ensure your hinges use brass or oil-impregnated bushings to prevent this.

Q4: Can I use a hinge rated for 100kg on a 100kg door? A: Generally, no. The rated load is usually static. If the door moves, vibrates, or faces wind resistance, you need a Safety Factor. For a 100kg door, we typically recommend a hinge rated for at least 150kg to 200kg to account for dynamic stresses.

-768x768.png)