HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Across modern product design, space has quietly become one of the most constrained resources—often more limiting than structural strength itself.

Urbanization is driving smaller living and working environments. Modular products are expected to deliver more functionality within tighter footprints. At the same time, ergonomic standards demand easier access and safer interaction, even in compact layouts.

As a result, folding panels, rotating surfaces, and concealed mechanisms are no longer niche solutions—they are now mainstream design strategies.

In this context, position-holding hinges should not be viewed as simple hardware components. They function as active space-management elements, shaping how products move, stop, and remain usable within confined environments.

The Three Core Conflicts of Compact Design

Rather than starting with hinge technology, effective space-efficient design begins with understanding the underlying design conflicts.

1. Usable Space vs. Stowed Space

A product often needs to be large when in use, yet compact when stored.

Traditional solutions—support arms, brackets, external locks—solve one side of the problem while introducing bulk, visual clutter, or mechanical complexity on the other.

2. Stability vs. Flexibility

Fixed-angle designs limit usability. Fully free-moving panels introduce safety risks.

The real challenge lies in allowing movement without sacrificing positional stability. This requires torque consistency that does not degrade over time, ensuring reliability that meets or exceeds standard lifecycle requirements (e.g., 20,000+ operating cycles).

3. Ease of Operation vs. Mechanical Complexity

Adding components increases cost, failure points, and maintenance burden.

From the user’s perspective, the expectation is simple: open, position, and use—ideally in one motion.

Position-Holding Hinges: Turning Motion into a Design Asset

Position-holding hinges elevate the hinge from a passive connector to an active control point within the product architecture.

What “Position Holding” Really Means in Practice

It is not simply about preventing movement. Each controlled angle represents a distinct functional state. Different positions enable different use cases, effectively allowing a single product to support multiple spatial configurations.

Replacing Traditional Structural Elements

By controlling motion and holding force internally, position-holding hinges can eliminate the need for:

- Support arms

- Mechanical stops

- Secondary locking mechanisms

This consolidation reduces part count and simplifies assemblies. Furthermore, by utilizing compliant materials (RoHS/REACH), manufacturers can streamline global certification processes while creating products that are thinner, cleaner, and lighter.

Folding Furniture: Maximizing Utility in Minimal Footprints

Compact furniture provides a clear illustration of how controlled motion enables better space utilization.

How Space Transitions in Folding Designs

A single surface may serve as:

- A full working surface when fully deployed

- A temporary resting surface at partial angles

- A flush, unobtrusive element when stowed

Each transition depends on predictable, stable positioning that maintains a premium “feel” without requiring user adjustment.

Design Freedom Enabled by Position Control

Rather than a binary open/closed state, designers gain multiple functional angles. One hinge system can support different users, tasks, and environments—without adding structural complexity.

Industrial Cabinets: Efficiency and Safety in High-Density Environments

The same principles scale directly into industrial applications, where performance standards are critical.

The Reality of Industrial Access Constraints

Industrial cabinets and enclosures are characterized by:

- Dense internal components

- Narrow maintenance clearances

- One-handed operation during servicing

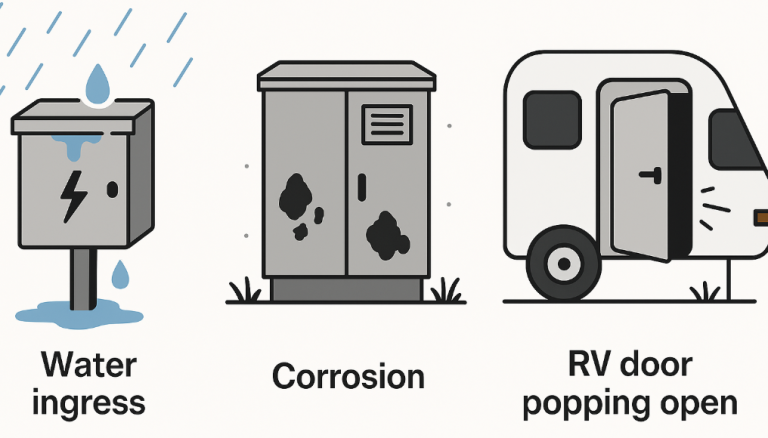

Uncontrolled doors and access panels quickly become obstacles—or hazards, particularly in dynamic environments subject to vibration and shock.

Improving Maintenance Through Controlled Motion

Position-holding hinges allow doors and access panels to remain exactly where technicians leave them, resisting drift even under vibration.

Engineered to withstand harsh environments—often validated against salt-spray corrosion standards (ASTM B117) and compatible with IP-rated sealed enclosures—these hinges prevent:

- Blocked access paths

- Accidental closures

- Panel rebound or impact damage

The result is safer operation, faster servicing, and reduced downtime.

Space Optimization Is Not About Smaller Products—It’s About Control

Effective space-efficient design is less about reducing size and more about managing movement.

From Saving Space to Reclaiming It

Hinges define motion paths. By controlling those paths, designers influence how people interact with equipment, furniture, and enclosures.

The outcome is a more predictable and intuitive relationship between user, product, and surrounding space.

The Hidden Value of Position Control

Well-implemented position-holding hinges deliver benefits that are often invisible—but deeply felt:

- Fewer accidental interactions

- Greater user confidence

- A perception of higher build quality through consistent torque

- Lower long-term maintenance costs (validated by rigorous endurance testing)

A Shared Perspective for Designers and Engineers

Designing with Hinges as Structural Strategy

When hinge behavior is considered early in the design process, it becomes part of the spatial concept—not a late-stage fix. This enables cleaner layouts and more intentional movement patterns.

Engineering Simplicity Through Functional Integration

Reducing parts does not mean reducing performance.

By integrating motion control into the hinge itself, engineers improve reliability while simplifying the overall system.

Conclusion

The most effective position-holding hinges rarely draw attention to themselves.

They simply work—holding panels where they should be, supporting safe interaction, and enabling compact designs to feel effortless.

From folding tables to industrial cabinets, space is not truly minimized.

It is precisely controlled.