HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Industrial hinge failures typically manifest as door sagging, corrosion seizure, and fatigue fracture. Although hinges represent a small percentage of the Bill of Materials (BOM), their failure often triggers significant increases in Total Cost of Ownership (TCO) due to unplanned downtime and Ingress Protection (IP) failure. By adopting ANSI/BHMA A156.1 (Cycle Life), ISO 9223 (Environmental Classification), and ISO 16047 (Torque Verification) as acceptance benchmarks, enterprises can effectively mitigate 80% of field delivery risks. This document aims to provide a standardized framework for risk control.

Risk Framing for Procurement

Hinge failures are often latent and progressive. At the procurement and delivery levels, these technical issues translate into three categories of explicit risks:

- Safety & Compliance Risks

- Door sagging leads to abnormal stress on mechanical structures, increasing the risk of detachment.

- Loosening fasteners result in the failure of equipment guarding, making it impossible to satisfy established safety interlock strategies.

- Functionality & Protection Risks

- Changes in seal compression lead to non-compliance with IP ratings (dust/water resistance).

- Dust or moisture ingress into the cabinet directly threatens the reliability of electrical components (PLCs/VFDs).

- Delivery & Maintenance Risks

- Increased opening resistance severely impacts the operational experience for the end-user.

- Batch cosmetic defects caused by spreading rust are a primary reason for project acceptance failure.

Core Failure Modes and Field Diagnosis

This section is structured around the logic of “Phenomenon → Cause → Input → Acceptance,” facilitating direct application in supplier audits and Incoming Quality Control (IQC).

Door Sagging & Wear

- Phenomenon: Uneven door gaps; difficulty in latch alignment; increased play at the hinge knuckle accompanied by friction noise.

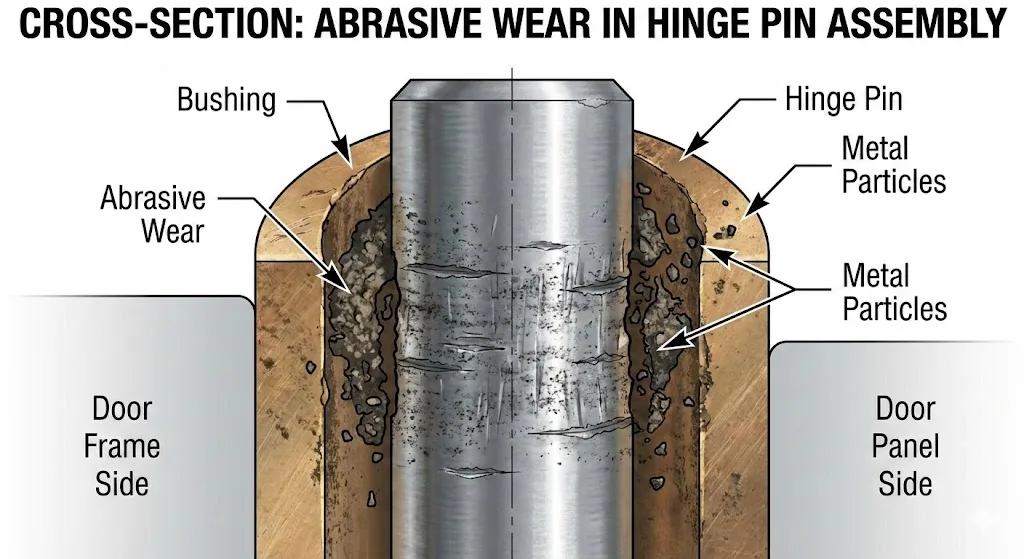

- Common Causes: Cumulative wear of the pin and bushing under cyclic conditions; abrasive wear caused by dust entering the friction pair; selection failure to account for dynamic load torque.

- Procurement Inputs (Specs):

- Target Life: Define cycle count (e.g., 20,000 Cycles).

- Operating Conditions: Dust, Outdoor, Washdown, Temperature differential.

- Load Data: Door weight, Door width, Center of Gravity (CG) offset (used for torque calculation).

- Acceptance Points:

- IQC: Consistency of key mating dimensions and assembly clearance.

- Verification: Perform durability sampling tests based on ANSI/BHMA A156.1 or EN 1935.

Corrosion & Seizure

- Phenomenon: Continuous increase in opening resistance; rust spreading from the pin area to the leaves; blistering and peeling of coating.

- Common Causes: Insufficient environmental classification (e.g., using standard coatings in salt spray/chlorine environments); lack of maintenance; galvanic corrosion.

- Procurement Inputs (Specs):

- Environmental Classification: Reference ISO 9223 to define atmospheric corrosivity categories (C3/C4/C5).

- Verification Standard: Specify ISO 9227 salt spray test methods and acceptance criteria (Note: Salt spray is for process screening only).

- Acceptance Points:

- IQC: Integrity of coating coverage, especially at edges and holes.

- Traceability: For high-corrosion environments, require material grade certification and surface treatment process records.

Fatigue Fracture

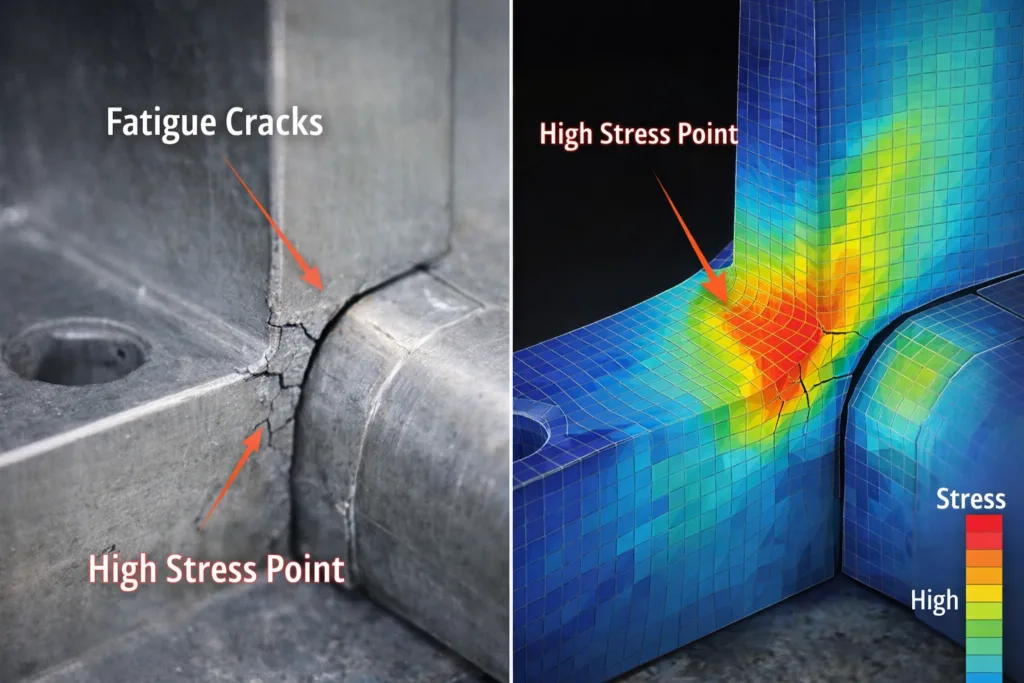

- Phenomenon: Micro-cracks appearing at mounting holes/bending roots; sudden fracture under extreme shock.

- Common Causes: Excessive eccentric load torque; center of gravity shift due to post-installation of door accessories; insufficient stiffness of the mounting surface.

- Procurement Inputs (Specs):

- Torque Definition: $Torque (M) = Door Weight (W) \times CG Distance (d)$.

- Safety Factor: Clarify load calculation assumptions and safety margins.

- Acceptance Points:

- IQC: No micro-cracks or burrs at stamping bends.

- Verification: First Article samples must undergo full-load simulation testing.

Material Selection Boundaries and Applicability

The core of material selection lies in “Condition Matching” rather than pure cost.

| Material Solution | Relative Cost | Corrosion Boundary | Typical Application Scenarios | Procurement Focus |

| Zinc Die-Cast (Coated) | Low-Med | Dependent on Coating | Indoor cabinets, Instrument cases | Coating adhesion & integrity acceptance |

| Carbon Steel (Coated) | Low | Dependent on Surface Treatment | Heavy-duty doors, Construction machinery | Edge rust protection & plating thickness |

| Stainless Steel 304 | Med-High | General Corrosion Resistance | Outdoor, Food non-contact zones | Risk assessment needed for high-chloride environments |

| Stainless Steel 316 | High | Strong Corrosion Resistance | Coastal, Chemical, Medical | Evaluate cost based on TCO |

Common Installation Failures and Controls

Approximately 30% of failures originate from improper installation. Clarifying installation prerequisites is key to defining liability.

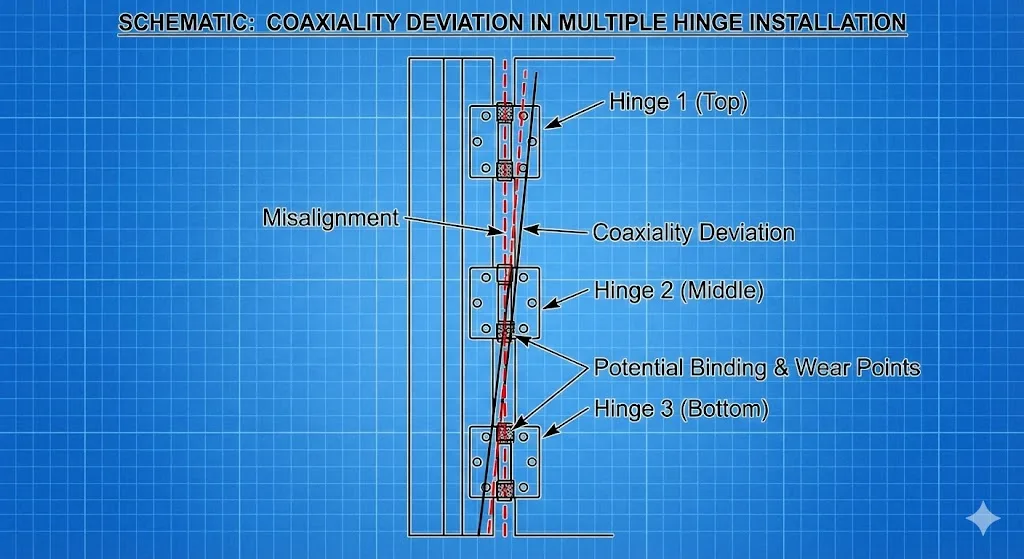

- Coaxiality Deviation: Misalignment of hinge axes in multi-hinge setups leads to torque spikes and premature wear.

- Control: Assembly SOP must include coaxiality calibration steps (e.g., using jigs).

- Welding Thermal Distortion: High welding temperatures cause internal structural deformation or lubricant failure.

- Control: Limit heat input or adopt a “weld-then-assemble” detachable pin structure.

- Uncontrolled Torque: Excessive torque leads to stripped threads; insufficient torque leads to loosening.

- Control: SOP must specify torque values, recommending reference to ISO 16047.

TCO Assessment Model

Procurement decisions should be based on full lifecycle costs, not single component unit prices.

- Calculation Model: $TCO = Acquisition Cost + (Failure Rate \times Cost per Single Failure Incident)$

- Failure Incident Cost Items:

- Downtime losses (Production interruption).

- Field service travel and labor (especially for overseas projects).

- Spare parts logistics and tariffs.

- Loss of customer trust (Intangible assets).

- Conclusion: Locking in lifecycle and environmental metrics via the RFQ at the front end is the most effective means of reducing TCO.

Standardized Procurement Acceptance Clauses

It is recommended to incorporate the following clauses directly into the RFQ (Request for Quotation) technical annex or PO (Purchase Order) terms:

1. Durability Requirements

“Products delivered by the Supplier must meet the specified cycle life metrics. Unless otherwise stated, durability verification shall be performed in accordance with ANSI/BHMA A156.1 or EN 1935 standards. The Supplier shall provide test reports containing loading methods, sample quantities, and pass/fail results during the PPAP stage.”

2. Environmental Adaptability & Corrosion Protection

“Products must meet the Environmental Corrosivity Category [Insert Level, e.g., C3] as defined by ISO 9223. Corrosion protection verification shall be executed according to ISO 9227 salt spray tests, with clear acceptance limits defined for blistering and rust area. Where IP protection is involved, the structure must coordinate with the system to meet IEC 60529 requirements.”

3. Installation & Technical Support

“The Supplier shall provide standard installation guidelines, which must include hole position tolerances, mounting surface flatness requirements, recommended tightening torques (referencing ISO 16047), and recommendations for multi-hinge coaxiality control.”

FAQ

Q1: Can industrial hinges be truly “Maintenance-Free”?

A: By adopting self-lubricating bushings or sealed bearing structures, maintenance frequency can be significantly reduced. However, under extreme conditions such as high dust, high-frequency cycling, or chemical washdowns, hinges must still be included in the periodic Preventative Maintenance (PM) Plan.

Q2: How do I define the selection boundary between SUS304 and SUS316?

A: The primary basis is the concentration of corrosive media. In environments within 5km of the coastline, or where high chloride ions or chemical splashes are present, SUS316 must be selected. For general outdoor or indoor environments, SUS304 offers a better cost-benefit ratio.

Q3: How reliable are Zinc Die-Cast products?

A: In indoor and low-corrosion environments, Zinc Die-Cast paired with mature surface treatments (such as electrophoresis/powder coating) meets the vast majority of application needs. The key lies in strict execution of coating system consistency verification (ISO 9227).