HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Test device handles are vital parts for ensuring the functionality and efficiency of various testing instruments. Whether it’s a basic instrument or a sophisticated equipment, the handles play a vital function in providing a safe and easy hold for the user. In this article, we will discuss the significance of Test device handles, their various kinds, and the important considerations to consider when buying them. Additionally, we will address four particular requirements relating to Test device handles, providing detailed understandings and resolutions to meet these needs effectively.

1. Safety and Ergonomics:

.png)

One of the primary demands of Test device handles is to ensure the safety and comfort of the user. Handles should be designed with ergonomics in mind, providing a non-slip grip and reducing the risk of hand fatigue or strain. This section will discuss the importance of ergonomically designed handles, materials utilized in their making, and how they help in a safer working environment.

2. Strength and Longevity:

Instrument handles are subjected to repeated use and may encounter severe conditions. As such, Strength and Longevity are essential considerations to take into account when selecting handles. This section will delve into the different materials available for handle fabrication, such as metal, plastic, and composite materials, and their respective pros and cons.

3. Tailoring and Suitability:

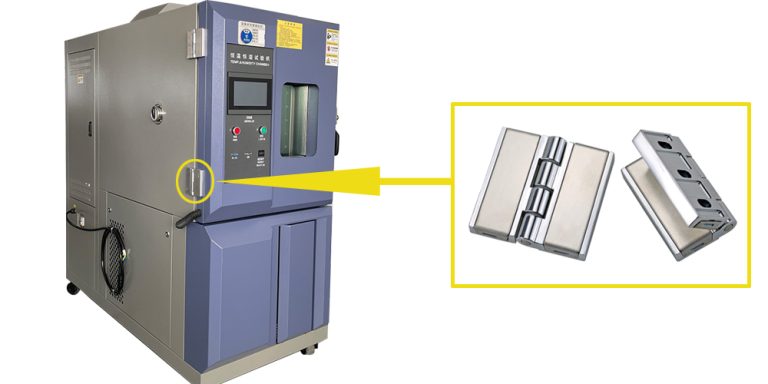

Instrument handles come in different forms, dimensions, and setups to accommodate different categories of testing apparatus. The demand for Tailoring and Suitability arises from the need to confirm that handles match perfectly with the particular apparatus being used. This section will explore the importance of suitability, the considerations to take into account when customizing handles, and how to find handles that meet the special needs of your testing instruments.

4. Performance and Functionality:

Testing equipment handles not only provide a grip but also serve other functions. They may include qualities such as adjustable length, rapid-release mechanisms, or built-in measurement indicators. This section will discuss the various performance and features of testing equipment handles, highlighting their impact on the overall effectiveness of the testing.

Security and Ergonomics:

Safety should always be a high priority when choosing testing tool handles. Comfortable handles are designed to reduce the risk of repetitive stress injuries and provide a easy grip, allowing users to work for long periods without weariness. handles constructed of materials like rubber or silicone materials offer a anti-slip surface, minimizing the probability of accidents. Additionally, handles with shapes or ridges can improve grip and lower hand fatigue.

Toughness and Durability over time:

When it comes to test apparatus Grip, Toughness is key. Grip should be able to withstand Ongoing use and exposure to Rough conditions without Degeneration. Materials such as Stainless material or Superior aluminum are known for their Robustness and Corrosion resistance. Synthetics, while lighter, can also be durable when Strengthened with Enhancers or designed with Strengthened structures. Evaluating the material and construction of Grip is crucial to ensure their Durability over time and Trustworthiness.

tailoring and Suitability:

test apparatus Grip are not one-size-fits-all. The demand for tailoring arises from the wide range of testing devices Accessible in the Industry. Grip should be Accessible in different Dimensions, Formations, and Set-ups to fit various equipment. Suitability is also essential to ensure that Grip integrate seamlessly with the Targeted instrument being used. This part will Investigate how to find Grip that meet the unique requirements of your test apparatus.

operation and operation:

examination device grips often offer extra functions that improve effectiveness and operation. Adjustable grips allow users to adjust the length to fit their ease and reachability. rapid-detach systems enable simple removal and reconnection of grips, saving time during the examination procedure. Integrated measuring scales provide confort and exactness when measuring lengths or sizes. This section will discuss the advantages of these features and how they contribute to the overall effectiveness of examination equipment.

examination device grips are essential parts that play a essential function in the operation and security of examination appliances. When buying grips, it is essential to take into account factors such as security, sturdiness, adjustability, and operation. By understanding the demands associated with examination device grips, users can make well-informed choices and choose grips that meet their unique requirements. whether it is making sure a firm hold, boosting user ease, or includeing includeitional operation, investing in superior standard examination device grips is a prudent decision for any examination setting.