HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Core Definition and Value of Torque Hinges

Core Definition

A torque hinge, also known as a friction hinge or position control hinge, is a precision mechanical component that uses internal friction to generate rotational resistance. Its core function is to allow a panel, lid, or display screen to be held stable at any angle within its range of motion, without the need for gas springs or external locking mechanisms. This “Free-Stop” capability is what fundamentally distinguishes it from traditional hinges.

Key Advantages

Compared to standard hinges that only provide a pivot point, torque hinges bring four key levels of value to product design:

- Safety: Effectively prevents heavy lids from slamming shut, reducing the risk of injury to operators or damage to equipment. This is crucial for industrial machinery and medical devices.

- Ergonomics: Enables “hands-free” operation. Maintenance personnel can focus on their tasks without needing to prop up a panel, significantly improving work efficiency.

- Design Simplicity: Integrates support and positioning functions into one component, replacing additional components like gas springs. This saves space, reduces weight, and creates a cleaner, more modern appearance.

- Precise Positioning: Provides smooth, controlled positioning for medical monitors, industrial control panels, and more. Users can easily adjust components to the optimal viewing angle and have them stay put.

Adopting torque hinges reflects an evolution in design philosophy from meeting basic functions to pursuing a superior user experience—an investment in product safety, usability, and design.

Internal Working Principle: How Friction Generates Controlled Torque

Core Mechanism

The fundamental principle of all torque hinges is to generate controlled friction within the pivot axis through a specific internal structure. As the panel rotates, internal components press against or move relative to each other, converting kinetic energy into thermal energy. This produces a resistive moment, or torque, that opposes the direction of motion. This torque counteracts the gravitational moment of the panel, allowing it to hold at any angle.

Mainstream Torque Generation Structures

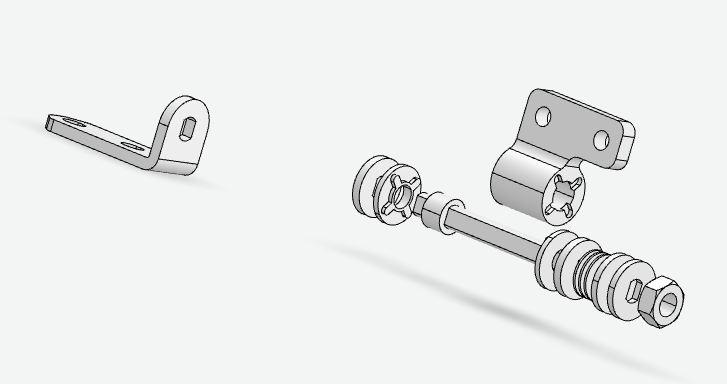

Exploded Structure of a Torque Hinge Assembly

There are various ways to generate friction inside a hinge, and different structures determine the hinge’s torque stability, lifespan, and cost.

- Friction Disc Structure: One of the most precise and stable designs. It consists of alternating stacks of fixed and rotating friction discs. An axial load, applied by elastic elements like disc springs (Belleville washers), compresses the discs together. The torque output is stable, making it common in high-precision industrial and medical equipment.

- Curl Spring/Leaf Spring Structure: This design tightly wraps a flexible metal spring (leaf spring) around a central shaft. As the shaft rotates, it rubs against the inner wall of the spring, generating resistive torque. This design is simple, cost-effective, and widely used in consumer electronics such as laptop screens.

- Damper/Hydraulic Structure: These hinges are sealed and filled with a high-viscosity silicone oil or hydraulic fluid. As the hinge moves, internal vanes move through the viscous fluid, producing a smooth damping force. Some designs integrate a one-way valve to achieve a “soft-close” effect, common in high-end cabinetry.

- Clip/Clutch Structure: Utilizes a combination of a one-way clutch and a torsion spring. In the designated torque direction, the clutch engages, generating positioning torque; in the opposite direction, the clutch disengages, allowing free motion. This is the most direct way to achieve a one-way torque hinge.

Table 1: Comparison of Torque Generation Mechanisms

| Mechanism | Torque Stability | Adjustability | Size | Cost | Typical Application |

|---|---|---|---|---|---|

| Friction Disc | Very High | Good | Compact | Med-High | Industrial Equip, Medical Monitors, Aerospace |

| Curl Spring | Medium | Limited | Small | Low | Laptops, Small Consumer Electronics |

| Damper | High | Adjustable | Med-Large | High | High-end Cabinetry, Automotive Interiors |

| Clutch | High | Usually Not | Medium | Medium | One-way opening equipment lids |

A Complete Classification System for Torque Hinges

By systematically classifying hinges by their function and structure, engineers can precisely define their needs. A single hinge can have multiple attributes (e.g., “concealed, adjustable, one-way, lift-assist torque hinge”).

By Torque Direction

- One-Way Torque Hinge: Provides resistive torque in only one direction of rotation, while moving freely in the opposite direction. Ideal for heavy top-access lids that need to be lifted easily but must be held securely in the open position.

- Two-Way/Symmetric Torque Hinge: The most common type. It provides the same or similar resistive torque in both the opening and closing directions. Suitable for applications requiring arbitrary positioning in both directions, such as laptop screens.

By Torque Adjustability

- Constant Torque Hinge: The torque value is pre-set at the factory. This is a “plug-and-play” solution suitable for standardized applications where the panel weight is known.

- Adjustable Torque Hinge: Allows the user to fine-tune the torque value in the field, typically via an adjustment screw or nut. This is essential for matching the “feel” of a panel, compensating for weight tolerances, or balancing accessories added later.

By Special Function

- Detent Hinge: In addition to the free-stop function, it has “detent” points set at specific angles (e.g., 0°, 90°). Some advanced designs release the torque near the closed position to ensure the panel closes completely without an additional latch.

- Lift-Assist Hinge: Integrates an internal spring mechanism whose force counteracts some or all of the gravitational force, making it exceptionally easy to open heavy panels. It combines the positioning function of a torque hinge with the lifting power of a gas spring.

By Mounting Style

- External/Butt Hinge: The most traditional mounting style. The hinge leaves are fixed to the outer surfaces of the frame and panel, making installation easy.

- Concealed Hinge: When the door is closed, the hinge body is completely hidden from view. This creates an extremely clean, seamless visual effect and is a go-to choice for modern high-end designs.

- Multi-Axis/Swivel Hinge: Provides more than one axis of rotation, enabling complex, compound movements (such as tilting and swiveling simultaneously). This is a core component for adjustable displays and POS screens.

Torque Calculation and Key Parameters

Elevating torque hinge selection from an educated guess to an engineering science is key to project success.

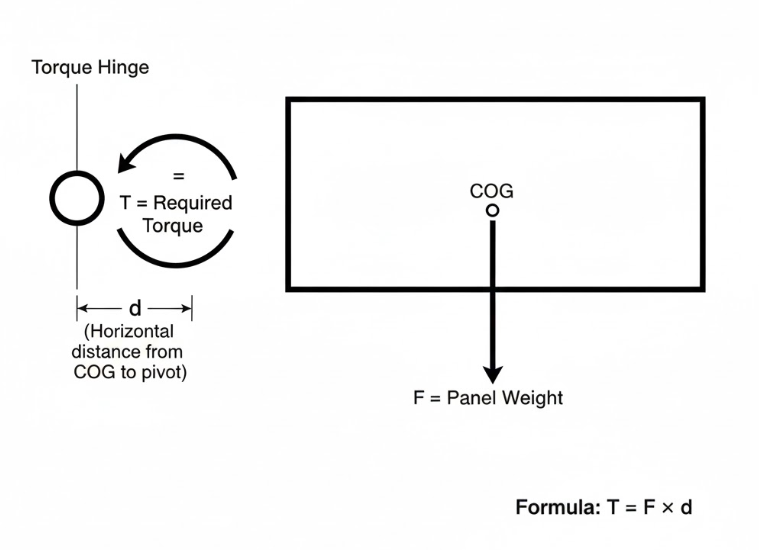

The Golden Rule of Torque Calculation

Torque Calculation Principle — Relationship Between Force, Distance, and Required Torque

The principle of torque calculation is that torque equals force multiplied by the lever arm (T = F × d). In a hinge application, the specific formula is:

Required Torque (N·m) = Panel Weight (kg) × 9.81 m/s² × Horizontal distance from COG to pivot (m)

This formula calculates the maximum gravitational moment generated when the panel is in the horizontal position. The total torque provided by the hinges must be greater than or equal to this value.

Step-by-Step Calculation Guide

- Determine Panel Weight (m): Accurately weigh or calculate the total weight of the panel, including all attachments (handles, screens, etc.).

- Locate Center of Gravity (COG) and Determine Lever Arm (d): For a uniform rectangular panel, the COG is at its geometric center. The lever arm (d) is the horizontal distance from the hinge’s pivot center to the vertical line of the panel’s COG (when the panel is open horizontally).

- Calculate Maximum Total Torque (T_total): Plug the values from steps 1 and 2 into the formula to calculate the maximum torque required for the entire panel.

- Distribute to Individual Hinges (T_hinge): Divide the total torque by the number of hinges you plan to use (typically 2) to get the torque value each hinge must provide.

Interpreting Key Parameters

- Torque Tolerance: This is a decisive parameter. Manufacturers will typically specify a tolerance range, such as

1.0 N·m ± 20%. This means the actual torque of the hinge could be anywhere from0.8 N·mto1.2 N·m.

Selection Key: You must ensure that your calculated torque requirement is less than or equal to the hinge’s minimum torque value (i.e., the nominal torque minus the tolerance percentage). Ignoring tolerance will result in a percentage of products failing due to insufficient torque, leading to costly repairs. - Cycle Life: Cycle life defines the hinge’s durability. A high-quality industrial hinge should be clearly defined as “After N opening/closing cycles, the dynamic torque remains within ±20% of its initial value.” For example, many industrial hinges are tested for at least 20,000 cycles. For high-demand applications like architecture, you can refer to authoritative standards like ANSI/BHMA A156.1, where a Grade 1 rating requires passing 2.5 million cycles.

Material Science: Choosing the Right Hinge for Harsh Environments

The hinge’s material determines not only its mechanical strength but also its lifespan in specific environments.

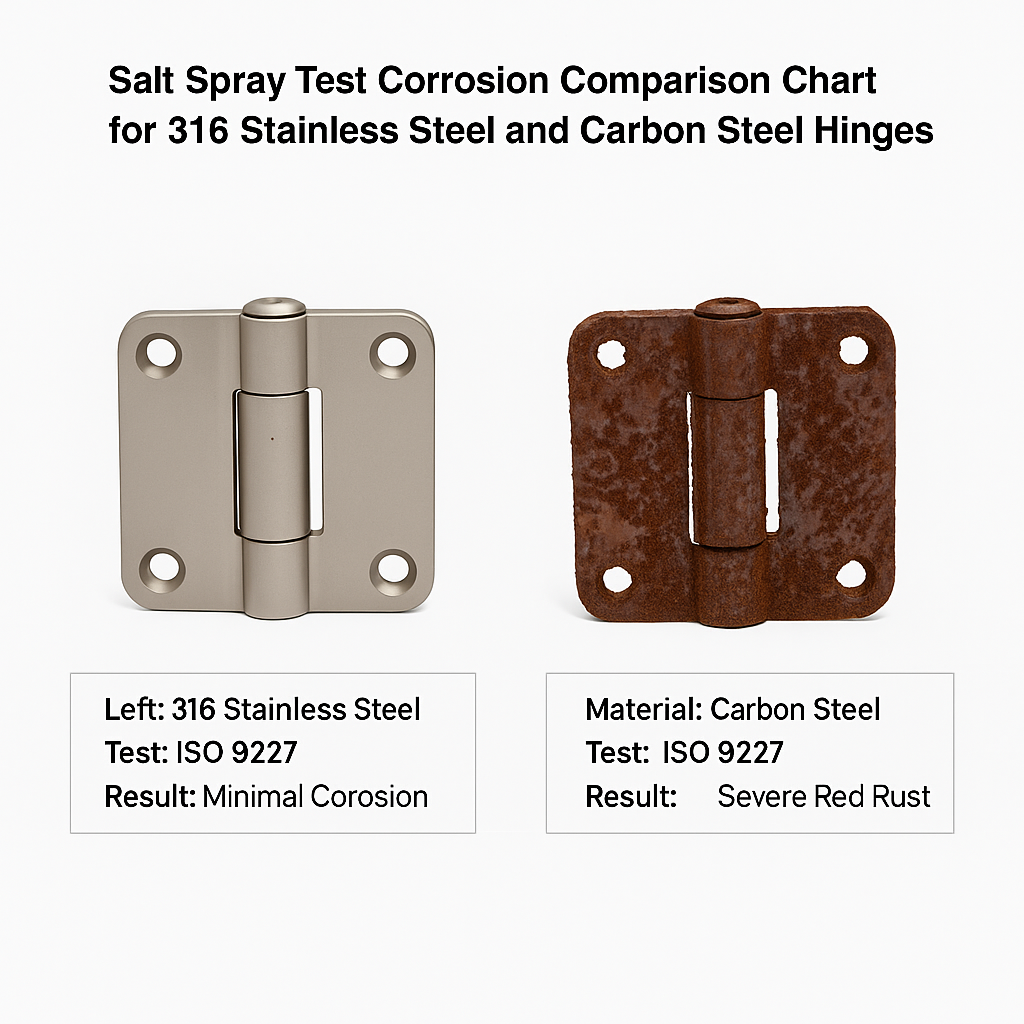

Stainless Steel: The Gold Standard for Durability

- Grade 304 Stainless Steel: Provides excellent general-purpose corrosion resistance. Suitable for indoor industrial equipment, food processing machinery, and mild outdoor environments.

- Grade 316/316L Stainless Steel: Adds 2-3% molybdenum to the 304 formulation, which creates a qualitative leap in its resistance to chlorides (like salt spray, seawater) and acidic substances. Therefore, 316 stainless steel is the mandatory choice for harsh applications such as marine environments, coastal areas, and chemical processing equipment.

Other Metal Materials

- Aluminum Alloy: Its primary advantage is its extremely high strength-to-weight ratio. It is much lighter than steel and has good natural corrosion resistance. It is the ideal material for fields with urgent weight-reduction needs, such as aerospace and portable equipment.

- Zinc Alloy: Inexpensive and easily die-cast into complex shapes. It has moderate strength and corrosion resistance, suitable for indoor, lighter-load applications, and usually requires plating or coating.

- Carbon Steel: Offers the highest mechanical strength at the lowest cost, but has extremely poor corrosion resistance. It must be protected by a reliable anti-corrosion treatment such as hot-dip galvanizing, plating, or powder coating, or it will rust quickly.

Quantitative Standards for Corrosion Resistance

The authoritative standard for evaluating corrosion resistance is the ISO 9227 salt spray test (highly equivalent to North America’s ASTM B117). A hinge’s corrosion resistance is often measured by the number of hours it can endure a salt spray test without showing red rust.

Table 2: Hinge Material Properties and Application Environment Comparison

| Material | Corrosion Resistance | Strength | Weight | Cost | Recommended Environment |

|---|---|---|---|---|---|

| SS 316 | Excellent | High | High | Highest | Marine, Chemical, Coastal, Medical |

| SS 304 | Good | High | High | High | Indoor, Industrial, Mild Outdoor |

| Aluminum | Good | Medium | Low | Medium | Aerospace, Portable Equipment |

| Zinc Alloy | Fair | Medium | Med-High | Low | Indoor, Consumer Goods |

| Coated Steel | Coating-Dependent | Very High | High | Lowest | Dry Indoor, Cost-sensitive applications |

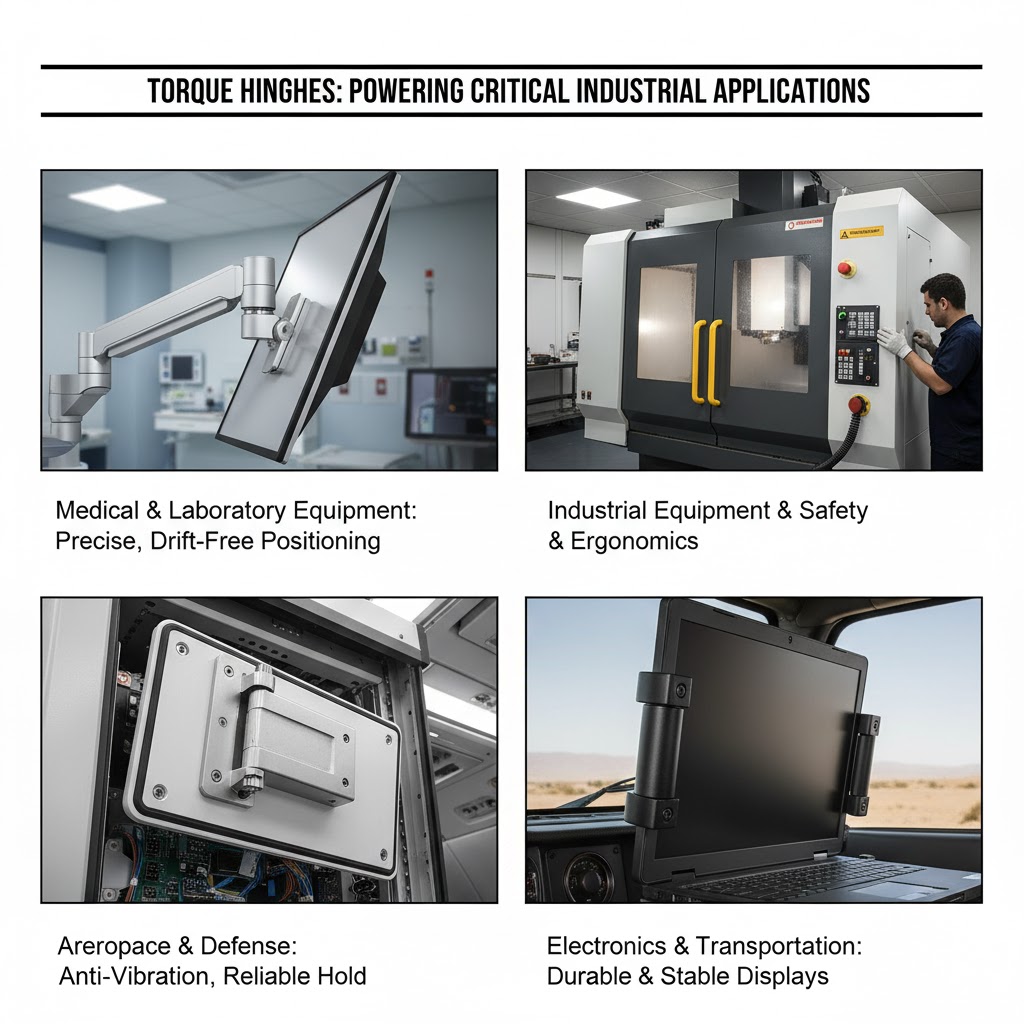

Typical Industrial Applications

The application range for torque hinges is extremely broad:

- Industrial Equipment & Automation: Used for heavy access doors and safety guards on CNC machines and electrical control cabinets, ensuring maintenance worker safety.

- Medical & Laboratory Equipment: Used for adjustable medical monitor arms, surgical lights, and centrifuge lids, providing smooth, drift-free positioning.

- Automotive & Transportation: Used for center consoles, glove boxes, and infotainment screens, providing reliable positioning and a premium tactile feel.

- Aerospace & Defense: Used for aircraft access panels and ruggedized laptops, maintaining position even under intense vibration.

- Electronics & Office Equipment: The laptop screen pivot is the most classic application, but they are also used in all-in-one PCs, printer lids, etc.

- Retail & Commercial Equipment: Used for angle-adjustable POS terminals and self-service kiosks to withstand high-frequency public use.

Installation, Adjustment, and Maintenance Protocols

Correct installation, adjustment, and maintenance are essential to ensure the hinge performs optimally.

Installation Guidelines

- Fastener Selection: You must use the screw size and strength grade specified by the manufacturer.

- Precise Positioning and Alignment: When installing, you must ensure the hinge pivot axes are parallel to each other. Any misalignment will cause binding and dramatically shorten the hinge’s life.

- Torque Fastening: Use a torque wrench to tighten bolts to the manufacturer’s recommended torque value. Over-tightening or under-tightening can lead to failure.

Torque Adjustment Method

For adjustable torque hinges:

- Locate the adjustment mechanism (usually a hex socket screw or nut).

- Turning clockwise generally increases torque (tighter); turning counter-clockwise decreases torque (looser).

- After each adjustment, you should open and close the panel several times until the desired “feel” is achieved.

Maintenance and Lubrication

- Manufacturer First Principle: The most authoritative guide will always come from the manufacturer. Many high-performance hinges are sealed and maintenance-free, having been filled with long-life specialty grease at the factory. Do not add any additional lubricants to such products, as this will attract dust and destroy the hinge’s operation.

- Best Practices for General Industrial Hinges: For non-sealed traditional hinges, lubrication is recommended every 3-6 months (shorten the interval for harsh environments).

Recommended: Use white lithium-based grease for high loads. Use a silicone-based spray for light loads or where plastic components are present. Use a dry Teflon (PTFE) lubricant for dusty environments. - Avoid: Never use cooking oil, petroleum jelly, or general-purpose penetrating rust inhibitors (like WD-40) as long-term lubricants. They will break down quickly and attract contaminants, accelerating wear.