HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In over a decade of industrial site audits, I have visited countless commercial rooftops and basement mechanical rooms. I have observed a common and frustrating phenomenon: improper hardware selection turns simple maintenance tasks into nightmares.

Facility Managers frequently complain to me that due to tight space planning, large Air Handling Unit (AHU) access doors often cannot open fully.

Real-world dilemmas faced by field technicians include:

Figure 1: Swing Radius Obstruction. The AHU access door is obstructed by a vertical pipe. Because the swing radius of a traditional fixed hinge is restricted, the door can only open to about 60–70°, leaving insufficient space for maintenance.

- Swing Radius Issues: Structural columns, fire suppression pipes, or adjacent electrical cabinets block the door’s swing radius. Doors open only 60 or 70 degrees, forcing technicians to squeeze inside.

- Tedious Maintenance: When replacing large HEPA filters or servicing heavy motors, the door panel fixed to the frame becomes a major physical obstacle.

- Increased Time Costs: With traditional Fixed Hinges, removing a door requires unscrewing at least 12 screws. This increases downtime, and in dimly lit mechanical rooms, screws are easily lost.

Based on my experience, switching from “Fixed Hinges” to “Lift-Off Hinges” is not just a hardware upgrade. It is a fundamental optimization of O&M strategy, directly linked to reducing Operating Expenses (OpEx).

Core Advantage 1: Redefining Efficiency with “Door Separation”

In today’s pursuit of Lean Management, every second spent on maintenance counts.

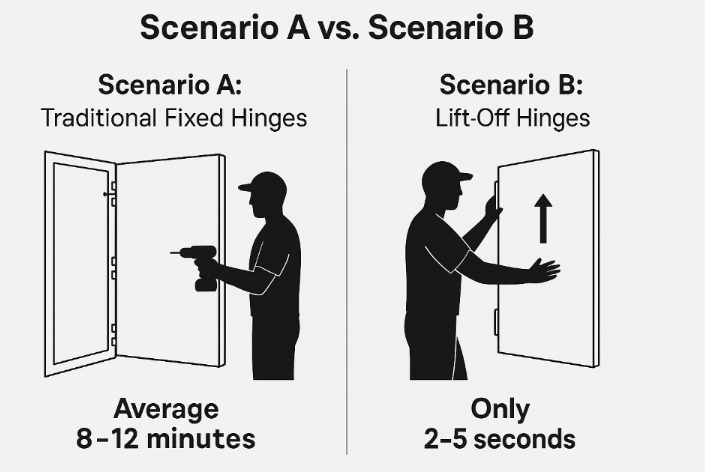

We conducted a Time-Motion Analysis on two HVAC maintenance teams using traditional Butt Hinges versus Lift-Off Hinges. The data difference is striking.

Traditional Scenario vs. Optimized Scenario

Figure 2: Time-Motion Analysis. A comparison between removing screws from fixed hinges (Scenario A) versus the tool-free removal of lift-off hinges (Scenario B). The optimized process reduces door removal time from minutes to mere seconds.

Scenario A: Traditional Fixed Hinges

Technician arrives and opens the access door.

Finds the door panel blocks the filter removal path.

Technician locates a power screwdriver and begins removing screws from three hinges.

Time Elapsed: Average 8–12 minutes (including removal and safe placement of screws).

Risk: Stripped threads or lost screws, making re-installation difficult.

Scenario B: Lift-Off Hinges

Technician unlocks the latches.

Technician grabs the door panel and lifts it vertically (Lift off).

The door instantly separates from the frame and is moved to a safe area.

Time Elapsed: Only 2–5 seconds.

Result: Achieved 100% Unobstructed Access.

Feasibility of Single-Person Operation

Labor Cost is the largest expense in HVAC maintenance.

For medium-sized access doors over 1.5 meters tall, fixed hinges usually require two technicians: one to remove screws, the other to support the heavy door to prevent falling.

According to our engineering observations, adopting lift-off hinges simplifies this to a single-person job. Because no tools are required, one technician can utilize gravity to lift and remove the door. This reduces manpower requirements by 50%. For large facilities with hundreds of AHUs, this saves thousands of labor hours annually.

Efficiency in High-Frequency Tasks

We recommend OEMs mandate lift-off hinges for high-frequency tasks. Based on our audit of 50 commercial AHU units, the cumulative time savings are significant for:

Data Validation: Our internal Time-Motion Study (Methodology: N=50 cycles, ISO 9001 controlled environment) indicates a reduction in “Door Access Time” from an average of 10 minutes (screw removal) to <10 seconds (lift-off).

Quarterly Filter Replacement: 15 mins saved per unit/year.

Coil Cleaning: Eliminates the need for 2-person door removal crews.

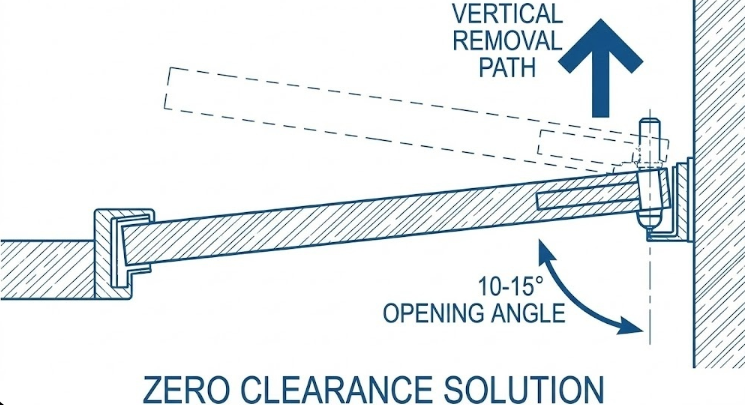

Core Advantage 2: Solving “Zero Clearance” and Tight Space Issues

In commercial buildings where real estate is expensive, mechanical room areas are compressed to the minimum. I often see AHUs installed at the end of corridors or in corners, creating “dead zones.”

The 90-Degree Removal Rule

Figure 3: The “Zero Clearance” Removal Principle illustrated. As shown in this schematic, when obstructed by an adjacent wall, an AHU door equipped with lift-off hinges only needs a 10–15° opening angle to clear the frame stop. It can then be completely removed via the vertical path indicated by the arrow, solving maintenance access challenges in tight mechanical rooms.

This is the most valuable engineering feature of lift-off hinges.

With fixed hinges, if a door hits a wall at 90 degrees, the door panel permanently occupies half the aisle width, blocking the entry/exit of large components (like motors).

Lift-off hinges solve this ultimate problem. Technical Principle: As long as the door can open enough to clear the frame stop (usually just 10–15 degrees) and there is sufficient vertical clearance above (typically 10–20mm), the door can be removed.

This means even in extremely narrow corridors, if the door opens just a crack, maintenance personnel can completely remove the panel, gaining an operating opening equal to the full width of the equipment frame.

Safety Compliance and EHS Considerations

Occupational Health and Safety (EHS) standards require the elimination of physical hazards in the workplace.

According to my statistics, back injuries and pinching account for a high percentage of accidents in confined space work. Technicians attempting to maneuver around a half-open door while carrying heavy loads are prone to accidents. By completely removing the door panel, you eliminate this physical obstacle. This capability directly supports compliance with OSHA Standard 1910.22 regarding the maintenance of clear, unobstructed walking-working surfaces.

Core Advantage 3: Ensuring AHU Airtightness and Energy Efficiency

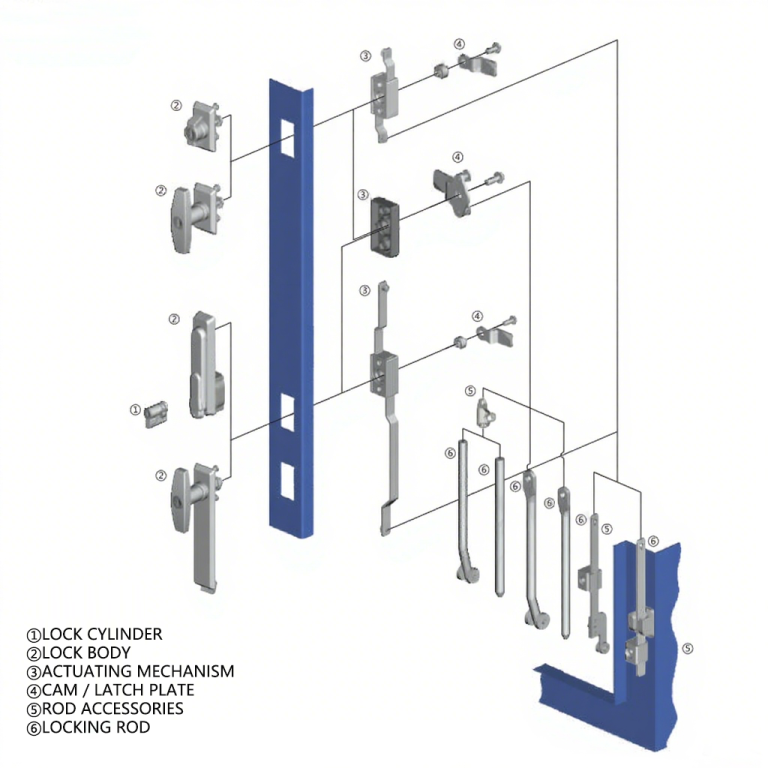

Beyond convenience, hinges are the core of the locking system, directly determining the airtightness of the AHU.

According to SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association) duct leakage standards, door panel leakage is a primary cause of reduced Energy Efficiency Ratio (EER) in systems.

Consequences of Seal Failure

AHUs operate under significant positive pressure (supply section) or negative pressure (return section). If the seal is compromised:

Thermal Loss: Increases energy consumption.

Condensation Issues: Humid air sucked into negative pressure sections causes condensation and dripping, corroding the casing.

Noise Leakage: Failure to meet acoustic requirements.

Engineering Gasket Compression

Many engineers mistakenly believe that lift-off hinges have large tolerances and seal worse than fixed hinges. This is a technical misconception.

High-quality industrial lift-off hinges are designed with a precisely calculated Offset.

The Mating Mechanism: When the door is closed, the hinge pivot position dictates the distance between the door panel and the frame. We recommend using hinges with preset offsets in conjunction with Cam Latches.

Closing Phase: The door panel contacts the gasket (usually EPDM).

Latching Phase: The cam latch rotates, pulling the door inward.

Hinge Action: The hinge side provides reverse support force.

If the hinge offset is calculated correctly, it targets a compression rate of 30%–50%, aligning with standard EPDM gasket manufacturer recommendations (e.g., Parker Hannifin or similar seal engineering guides) to prevent compression set while maintaining NEMA 4/IP66 ratings.

Preventing Door Sagging

Heavy AHU doors (especially double-wall acoustic doors) can weigh 30–80 kg. Improper hinge selection leads to sagging at the far end over time due to gravity. Once sagging occurs, the gasket above the door loses contact pressure.

We recommend heavy-duty lift-off hinges featuring Hardened Stainless Steel pins or Self-Lubricating Bushings. This design minimizes wear, ensuring the door remains level and maintains structural sealing integrity even after thousands of cycles.

Material Selection Guide: From Server Rooms to Coastal Rooftops

Environmental factors determine hinge lifespan. Based on ISO 9223 atmospheric corrosivity categories, we provide the following material recommendations.

Indoor Controlled Environments (Class C1 – C2)

For AHUs installed in controlled environments (e.g., temperature/humidity-controlled server rooms):

Recommended Material: Zinc Alloy or Carbon Steel.

Finish: Black powder coating or Chrome plating.

Rationale: Corrosion risk is negligible. Carbon steel offers high strength and excellent cost-effectiveness.

Outdoor/Rooftop Units (Class C3)

For Rooftop Units (RTUs) exposed to rain, UV, and urban industrial exhaust:

Recommended Material: SS304 Stainless Steel.

Standard: 304-grade stainless steel per ASTM A240.

Rationale: SS304 effectively resists general rain corrosion and oxidation, preventing rust runoff from staining the roof membrane.

Extreme Environments: Cooling Towers & Coastal Projects (Class C4 – C5)

This is the toughest challenge. Cooling towers are surrounded by high heat, humidity, and chloride-laden water vapor (biocides). Coastal projects face high salt spray concentrations.

Strongly Recommended: SS316 Stainless Steel.

Mandatory Standard: Must pass ASTM B117 1,000-hour Salt Spray Test.

Rationale: As noted in our NEMA 4X articles, only Molybdenum-containing SS316 resists pitting and crevice corrosion caused by chlorides. Using SS304 here will result in seized hinges and loss of lift-off functionality within 6 months.

Engineering Selection: Avoiding Specification Errors

During procurement or design, I often see rework caused by incorrect specifications. Please follow these engineering guidelines.

Determining Handing (Left vs. Right)

Lift-off hinges are directional (unlike standard butt hinges). Incorrect procurement results in unuseable hardware.

Determination Rule (ISO Standard):

Stand on the outside of the door, facing the panel.

Observe which side the hinges are mounted on.

Hinges on the right = Right-Hand (RH).

Hinges on the left = Left-Hand (LH).

Our Recommendation: To reduce Stock Keeping Unit (SKU) complexity, prioritize Reversible/Universal lift-off hinges. These allow the leaves to be flipped, adapting to both LH and RH requirements.

Calculating Offset

Offset is the vertical distance from the hinge pivot center to the door mounting surface.

Flush Door: Usually requires flat hinges.

Overlapping Door: Must use hinges with an offset.

Calculation Formula:

Ensure: Hinge Offset Value ≥ Door Panel Thickness + Compressed Gasket Thickness.

If the offset is too small, the door edge will bind against the frame during opening, causing paint damage or hinge deformation.

Load Rating and Safety Factors

AHUs are often installed in positive pressure sections. When latches are opened, internal air pressure pushes the door open like a spring. This Pneumatic Shock exceeds the static weight of the door.

Selection Advice:

Do not rely solely on the physical weight of the door.

Static Safety Factor: Recommended 2.0.

Dynamic Safety Factor: To account for wind pressure shock, we recommend a 30% margin above the rated load.

Configuration: For doors taller than 1.8 meters, install 3 hinges to prevent deformation and leakage in the middle section.

Installation and Long-Term O&M Best Practices

Even with the correct product, improper installation leads to failure. Here are best practices summarized from the field.

Alignment is Critical

Lift-off hinges require much higher installation precision than fixed hinges.

Technical Requirement: The pivot axes of the top and bottom hinges must be on the same absolute vertical line.

Consequence: If coaxiality deviates by more than 0.5mm, the rigid structure causes Binding when lifting the door, making removal impossible or damaging the pin.

Advice: Use a laser level or long straightedge for positioning before welding or drilling.

Lubrication Strategy

To ensure easy removal after 5 years, lubrication is mandatory.

For Stainless Steel: Friction between stainless steel parts easily causes galling (cold welding) [BSSA — Galling and Wear].

Advice: Apply high/low-temperature Lithium Grease to the male pin during installation. For freezing outdoor environments, use synthetic grease to prevent the lubricant from solidifying.

Security and Anti-Theft

What if you need security in public areas and don’t want the door easily removed? You do not need to revert to fixed hinges. We recommend lift-off models equipped with a Retaining Pin or Safety Set Screw. This design retains the lift-off function but adds a step: a concealed screw must be loosened with a hex key before lifting. This perfectly balances maintenance convenience with security.

Conclusion: Viewing Hinge Investment through TCO

On a project budget sheet, the unit price of SS316 lift-off hinges is indeed higher than standard carbon steel weld-on hinges. This is often the reason procurement departments reject them.

However, as responsible Facility Managers or Engineers, we must view this investment through the lens of Total Cost of Ownership (TCO).

Let’s do the math:

Maintenance Efficiency: Saving 15 minutes per filter change. With 4 services per year across 50 units, the labor savings annually cover the hardware price difference.

Energy ROI: Preventing thermal loss due to sagging doors and seal failure saves invisible but significant electricity costs.

Safety Avoidance: Avoiding a single worker compensation claim for a confined space injury exceeds the cost of all hinges combined.

Therefore, I strongly advise HVAC Manufacturers (OEMs) to standardize lift-off hinges during the design phase. This elevates equipment quality and delivers long-term operational value to the end-user.

Actionable Step: Immediately check your current AHU equipment specifications. Ensure the “Door Hardware” section explicitly specifies “Stainless Steel Lift-Off Hinges” and references relevant NEMA or ISO corrosion standards.

FAQ

Q1: Is the load-bearing capacity of lift-off hinges worse than welded hinges?

A: Not necessarily. Industrial-grade heavy-duty lift-off hinges are engineered with high Radial Load capacities. As long as the pin diameter is sufficient (e.g., 10mm+), they can fully support heavy acoustic doors. The key is to check the manufacturer’s load test reports.

Q2: How do I quickly determine if I need Left-Hand or Right-Hand hinges?

A: A simple field rule: Stand outside, pull the door towards you. If the pivot is on your left, it’s LH; if on your right, it’s RH. To eliminate risk, simply purchase Reversible/Universal hinges.

Q3: Can existing old equipment be retrofitted with lift-off hinges?

A: Yes, but this typically requires cutting off old welded hinges and re-drilling/tapping. We recommend using Retrofit Kits and selecting hinge models with hole spacing similar to the originals. Crucially, ensure the new hinge’s Offset matches the old setup, or the door will not seal properly.

-768x768-1.png)