HTAN은 중국 최고의 산업용 경첩, 핸들 및 래치 제조업체 중 하나입니다.

-

+86 13720060320

-

julius@haitangs.com

What are Adjustable Torque Hinges: Core Mechanism and Definition

HTAN Semi-Adjustable Torque Hinge Display

Ever had a cabinet door that slams shut? Or maybe a laptop screen that just won’t stay where you put it? That’s where adjustable torque hinges work their magic. These clever little hardware pieces are the real unsung heroes. They’re behind all that smooth, controlled movement in so many everyday things. Unlike regular hinges, adjustable torque hinges let you fine-tune the resistance. So lids, doors, and screens move just how you want – not too much, not too little. Whether you’re into DIY and working on a home project, or an engineer picking parts for medical gear, getting these hinges right is key. It’s all about that perfect, effortless motion. I learned this the hard way – a bad hinge choice once shattered my tablet screen. Definitely not making that mistake again!Table of Content

What is an Adjustable Torque Hinges: Core Mechanism and Definition

How Adjustable Torque Hinges Work: Principle, Friction Mechanism, and Structure

At its core, an adjustable torque hinge is really just a friction-based pivot.(HTAN Torque Hinge Introduction) Inside, it’s got a special mechanism—usually a cam and follower or a clutch—that creates steady rotational resistance.

That resistance is measured in Newton-meters (N·m), and it’s what gives you that smooth, controlled motion. The adjustable bit usually comes down to a simple screw or dial.

When you turn it, you’re basically tightening or loosening the internal friction plates or springs, which changes the torque. That’s why one hinge model can work perfectly for everything from a lightweight laptop lid to a heavy industrial access panel.

What really makes these hinges stand out from spring-based ones is how consistent they are. Springs change force as they move, but a good adjustable torque hinge keeps the resistance almost the same the whole way.

So whether you open something slow or fast, it feels the same. Materials matter a lot too—high-quality steel inside, and aluminum or zinc housing, make these hinges last through thousands of uses. That reliable, predictable performance is exactly why they’re essential for precision jobs.

Key Components and Materials

How long an adjustable friction hinge lasts and how well it works really depends on how it’s built. The heart of it is the friction mechanism, usually made from hardened steel so it can handle all that rubbing.

That mechanism sits inside a body made from die-cast zinc or aluminum, which keeps everything aligned even under pressure. They seal in high-grade lubricants to keep things running smooth and stop rust.

The adjustment screw is made from stuff that won’t strip, so you can adjust it over and over without wrecking it.

Besides metals, you’ll also see advanced polymers and composites in some parts—they help cut weight or cost for simpler jobs. The finish is key too—things like black oxide, zinc plating, or powder coating fight rust and look good.

When you’re picking a hinge, don’t just look at the torque rating—the materials are just as important. A hinge with high torque but cheap materials will break early, so that initial savings isn’t really saving you anything.

Key Features and Benefits of Using Adjustable Torque Hinges

Adjustable Torque Hinge Features: Customizable Resistance and Position Holding

The biggest perk of adjustable torque hinges? You guessed it – they’re adjustable. This lets you tweak them perfectly, both when you first install them and later on. Picture putting one on a heavy workshop jig.

You set the resistance so it stays put at any angle, no sagging, but still moves easily when you give it a push. That means you don’t need extra props or stays, which simplifies the design and makes it way easier to use. That hands-free operation is a huge deal and why people love them so much.

This adjustability also helps deal with wear and tear. Over time, all mechanical parts wear down a bit. A regular hinge might get loose and wobbly. But with an adjustable torque hinge, just turn a screw to take up the slack.

It brings back the original resistance and makes the whole thing last longer. This is a massive value-saver. It cuts down on maintenance costs and avoids full hinge replacements – something I’ve found super useful in my woodworking.

Durability and Smooth Motion Control

Good adjustable torque hinges are built to last. They’re made to work reliably for tens of thousands of cycles – we’re talking 25,000 to 50,000 or more – without really losing their grip.

That kind of reliability is key for stuff like consumer electronics or medical gear, where you just can’t have them fail. Their smooth, damped motion also protects whatever they’re attached to. It stops damage from slamming or jerky moves, which often breaks devices and furniture.

But it’s not just about protection; it’s also about feeling high-quality. A laptop screen that opens smoothly and stays put just feels premium and well-built. That feel directly shapes how a customer sees the product’s value.

Plus, the smooth action puts less strain on other parts like brackets and mounts, making the whole assembly tougher. So it’s a tiny part that seriously boosts the whole product’s quality and lifespan.

Common Applications and Industries for Adjustable Torque Hinges

HTAN HT302-1W Torque Hinge Product Application Demo

Consumer Electronics and Laptops

You’ll most often spot adjustable torque hinges in consumer electronics, especially laptops and tablets. They do a really important job: let you open the screen with just one hand, yet they provide enough

resistance to keep it steady at any angle you want, even if you’re in a moving car. Big names like Apple and Lenovo are super picky about these hinges.

They demand a precise torque curve to get that specific feel, which matches their brand’s vibe perfectly. These hinges need to be tough for everyday use but also gentle. They gotta protect those internal cables running through them from getting damaged.

But it’s not just laptops. You can also find these adjustable torque hinges in flat-screen TV stands. They let you easily tilt the screen to cut down on glare. They’re inside kitchen gadgets with lids too, think bread makers and stand mixers.

They give you safe and controlled access to what’s inside. Even gaming gear like VR headsets uses them. The adjustable torque hinges make for a comfy and customizable fit, no matter who’s wearing it.

This sector really wants things smaller and built to last through tons of use. That pushes hinge makers to keep innovating all the time.

Industrial, Medical, and Automotive Uses

Over in industrial settings, adjustable torque hinges are the real workhorses. You’ll find them on machine access panels, control console screens, and safety guards.

They make sure these parts stay open for maintenance but then shut tight and secure for normal operation. The medical field counts on them too. They’re on stuff like surgical light arms, monitor stands, and rolling laptop carts (COWs).

Precise positioning is key here for both procedures and keeping things sterile. Their motion is super smooth and controlled, which stops any sudden jerks that might mess up a sensitive environment.

Car makers put these hinges into vehicle infotainment screens, glove compartments, and center console lids. In cars, they’ve gotta work perfectly no matter the temperature, from freezing cold to blazing

heat, without their torque feeling any different. That means they need special lubricants and material treatments to handle it. Up in the aerospace industry, they’re in overhead compartments and folding trays.

In this case, reliability and keeping weight down are the top priorities. So every industry has its own tough standards that these small but crucial adjustable torque hinge components have to meet.

How to Select the Right Adjustable Torque Hinges for Your Project

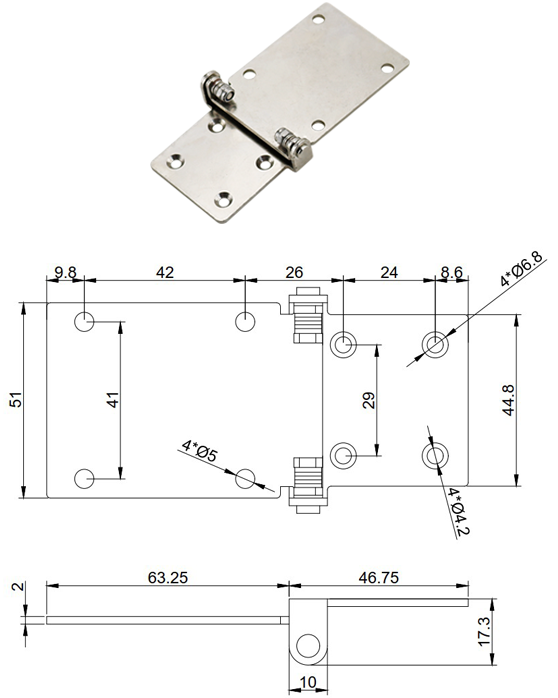

DP045 Product Dimension Drawing

Determining Torque Requirements and Size

Picking the right adjustable torque hinge begins with some basic physics. First, figure out the holding torque you need. This torque fights against the force created by the weight of your door or lid.

Here’s the formula: Torque equals the weight, times gravity (9.8), times the distance from the hinge to the center of mass. It’s smart to add a safety factor of 1.5 to 2.

This covers things like movement, wear and tear, and small differences in manufacturing. So for a 2 kg lid with its center of mass 0.2 meters out, you need a hinge rated for at least 3.92 N·m. To be safe, aim for an adjustable torque hinge around 6 to 8 N·m.

Size and shape are just as important. Think about how thick your panel is, how far you need it to open (like 180 degrees), and how you’ll mount it—surface, inset, or hidden. Looks matter too.

Do you want the hinge to be invisible, or part of the design? Before you buy, try making a cardboard mock-up or a 3D print. It’s a great way to see the motion and check if the adjustable torque hinge fits your design.

Considering Environmental and Load Factors

Where you’ll use it decides what materials you need. Is your adjustable torque hinge going outdoors or somewhere damp? If yes, get one with stainless steel parts that can really resist rust.

For hot spots, like near an engine, regular grease might not work. You’ll need an adjustable torque hinge built for extreme heat. On the other hand, in a cleanroom or hospital, the hinge might need

special certification for low outgassing. Or it might need non-porous materials to handle strong cleaners.

There’s more to load than just weight. Think about how the force is put on it. Is it a straight push, or is there a twisting force that could strain the mounts? How many times will it be opened and closed?

A commercial adjustable torque hinge might need a 50,000-cycle rating, but a home one may only need 10,000. Also, consider how often people will adjust it. If it’s often, then easy adjustment and a tough adjustment mechanism are key.

Talking to an engineer from a supplier like HTAN 또는 Southco can give you really helpful advice here.

Installation Tips and Maintenance Best Practices

Step-by-Step Mounting Guidance

Getting your adjustable torque hinge installed right is super important for it to work like it should. First things first, always use the screws they recommend—usually machine screws that fit nicely into the hinge’s threaded parts.

Stay away from self-tapping screws, they can mess up the material after a while. Next up, make sure the surfaces you’re mounting on are lined up perfectly. Even being a tiny bit off can make the hinge stick, causing uneven wear and a jerky movement.

Grab a jig or template to drill your pilot holes—it really helps get things spot on, especially when you’re putting on two hinges.

When you’re installing it, turn the adjustment screw to the middle before you mount it. That way, you’ve got some wiggle room to tweak the resistance later once everything’s tight.

After it’s on, just open and close the door a few times to let everything settle in. Then, make little adjustments to the screw, testing how it feels each time you turn it. Turning it clockwise usually makes it stiffer, counterclockwise loosens it up.

Don’t force the screw past where it stops, you could break the stuff inside. Take your time with this part, it really pays off.

Long-Term Care and Troubleshooting

You won’t need to do much to keep these hinges going. Mostly, you’ll just need to tweak them now and then as they wear in. If a hinge gets loose and you can’t tighten it anymore with the screw, it’s probably done for and needs swapping out.

Skip the WD-40 and other lubes—they just attract gunk and can gum up the works inside. Good hinges usually come with lube that lasts forever and are sealed tight to keep dirt out.

If it starts squeaking or feeling stiff, some dirt might have gotten inside. Sometimes you can try a bit of special cleaner, but often it’s safer to just get a new one.

If something’s wrong, always check the screws first—loose ones cause a lot of headaches. If the door starts to sag, make sure the hinge can handle the weight and the surface hasn’t warped. Giving them a quick look now and then can spot trouble early and stop a total breakdown.

Warranty, Support, and Purchasing Considerations

Understanding Manufacturer Warranties and Returns

Good adjustable torque hinge makers back their products with warranties. These usually last one to two years and cover any flaws in materials or workmanship. Make sure you get the terms: does the warranty include labor costs for replacements?

And what’s the process if you need to file a claim? Most will ask for your receipt and might want the faulty hinge back to check it out. A solid warranty is basically their promise of quality. It shows the company trusts its hinge to last.

Before you order a bunch, ask about their return policy for stuff you haven’t used. Many places let you return unopened items within 30 days. But if you order custom hinges, the rules are usually much stricter.

Always ask for a sample hinge to test first before you spend a lot of money. Doing this quick check can save you a ton of time and cash later on. I test a sample every time. Once, it stopped me from making a pricey error with a hinge that was a tiny bit too large.

Evaluating Suppliers and Technical Support

Picking a supplier isn’t just about who has the lowest price. You gotta see how good their tech support is. Can they give you detailed CAD files, torque charts, and engineering specs?

A reliable supplier will have engineers on hand to help you pick the perfect adjustable torque hinge. Check their lead times and stock levels too—can they keep up with your production schedule?

Well-known brands like 스가츠네, Southco, and HTAN are famous for being reliable and having great support.

Try to find suppliers who offer extras, like custom plating or pre-drilling the hinges just how you need them. Read reviews and ask for references, particularly from other businesses in your field.

A dependable supplier turns into a real partner for your product’s success. Lastly, think about how eco-friendly and socially responsible the manufacturer is.

Companies that care about being green and treating workers right usually make better, more reliable stuff. This matches the long-lasting performance you need from a precision part like an adjustable torque hinge.

So, to sum up, the adjustable torque hinge seems simple but fixes a common issue: it controls movement precisely and reliably. You’ll find it everywhere, from your laptop screen to spacecraft doors—its uses are huge and really important.

If you learn how it works, pick the right model, and install it properly, you can make any project work better and last longer. Don’t just put up with slamming doors or drooping screens. Check out adjustable torque hinges and see how much better things work with perfect control.

Here are some frequently asked questions about adjustable torque hinges.

Wondering how to make your hinge tighter?

First, find the adjustment screw on the hinge barrel. Grab the right tool – usually a hex key or the screwdriver that came with it. Then slowly turn the screw clockwise, just a quarter-turn each time.

After each tweak, test how much resistance there is. Keep going until it feels just right. Be careful not to over-tighten it though, or you might mess up the inside parts.

Can you use these hinges for heavy doors?

Yes, but you gotta pick one that’s made for your door’s weight and size. Figure out the torque you need with this formula: multiply the weight by the distance to the center of mass. And don’t forget to add a safety margin.

If the door’s really heavy, you might need several hinges to spread out the weight and keep things moving smoothly.

How long do these hinges usually last?

Their lifespan is measured in cycles – that’s each time you open and close them. Good quality hinges can handle 25,000 to 50,000 cycles, sometimes even more.

How long they actually last depends on how much weight they’re holding, where they’re used, and how often you open and close them. Adjusting them regularly helps keep them working well and makes them last longer.

Can you use them outdoors?

Only if they’re specifically made for outdoor or wet environments. These special models use materials like 316 stainless steel, plus they have seals and lubricants that can handle moisture, salt, and changing

temperatures without rusting. If you use a regular indoor hinge outside, it’ll probably break down much sooner.