HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

PRODUCT INFORMATION

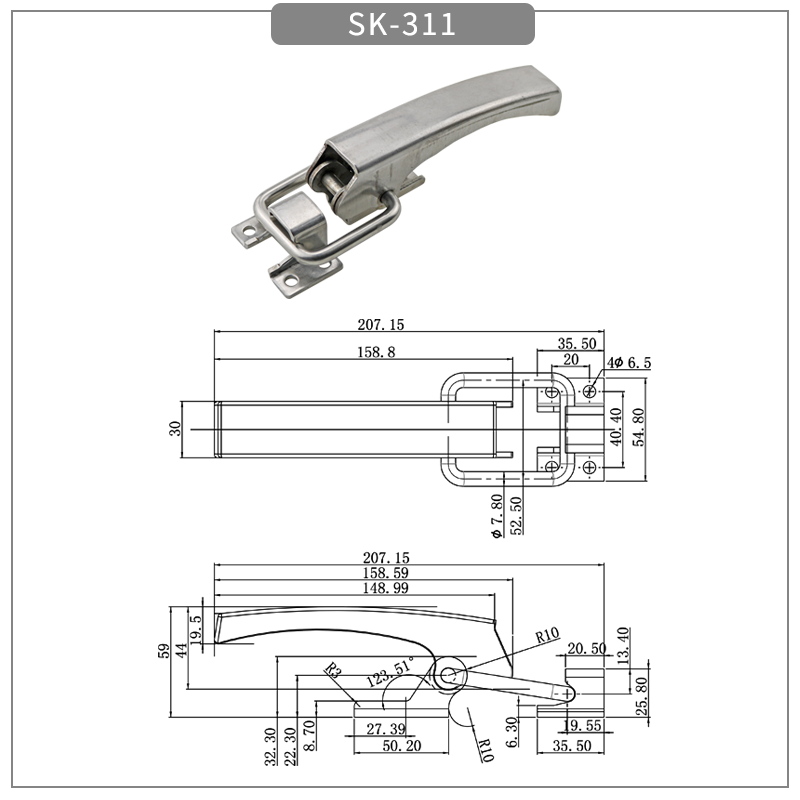

- Manufacturer: HTAN

- Model:SK311

- Material: stainless steel

- Surface treatment: vibration light

- Application Scenario:Ship container, heavy equipment, instruments and equipment

- Whether to support customisation: Yes

Description

Product Features

MATERIAL ADVANTAGE: Stainless steel is a corrosion and abrasion resistant material, commonly used in high-end locks.

Safety: stainless steel is resistant to damage and has good safety performance.

Convenience: Pressing is the operation that

Application Scenarios

In the field of construction and engineering machinery: toolboxes and equipment boxes of engineering machinery (such as cranes, loaders, etc.) at construction sites

Energy facilities: in power stations, substations, power distribution cabinets, energy storage equipment cabinets and other facilities.

Industrial equipment field: widely used in control cabinets and electrical cabinets of industrial equipment such as large machine tools, injection moulding machines, stamping presses, etc.

In the building HVAC industry: applied on large pipes of heating, ventilation and air conditioning (HVAC) systems in buildings

Other models: Safe Door Latch Buckle

Five Frequently Asked Questions

Problem 1: Latch lock is difficult to insert or pull out of the shackle

Solution: Check the surfaces of the latch and carabiner for obvious signs of wear or deformation. If there is slight wear, you can use sandpaper to sand the surface to make it smoother; if the deformation is serious, you may need to replace the latch or latch parts.

Problem 2: Loose or unstable latch after installation

Solution: Deviation in the hole position may result in the latch not fitting tightly after installation. At the same time, check whether the mounting screws are loose, if so, tighten the screws using the appropriate tools.

Problem 3: Rust and corrosion of the latch

Solution: Although it is made of stainless steel, if the quality of the stainless steel is not up to standard (e.g. the alloy composition does not meet the standard), it may still rust. If the rust is slight, you can use stainless steel cleaner and a soft cloth to wipe and remove the rust.

Problem 4: The locking strength of the latch is not enough, easy to open accidentally

Solution: Check if the latch is too short or too thin and consider replacing it with a stronger, properly sized latch.

Problem 5: Latch failure in low or high temperature environment

Solution: When designing and installing the latch, consider reserving a certain amount of expansion and contraction space for the latch, or choose a latch model that can adapt to a wide range of temperature changes.

-768x768.png)

-768x768.png)

-768x768.png)

-768x768.png)