HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

PRODUCT INFORMATION

- Manufacturer: HTAN

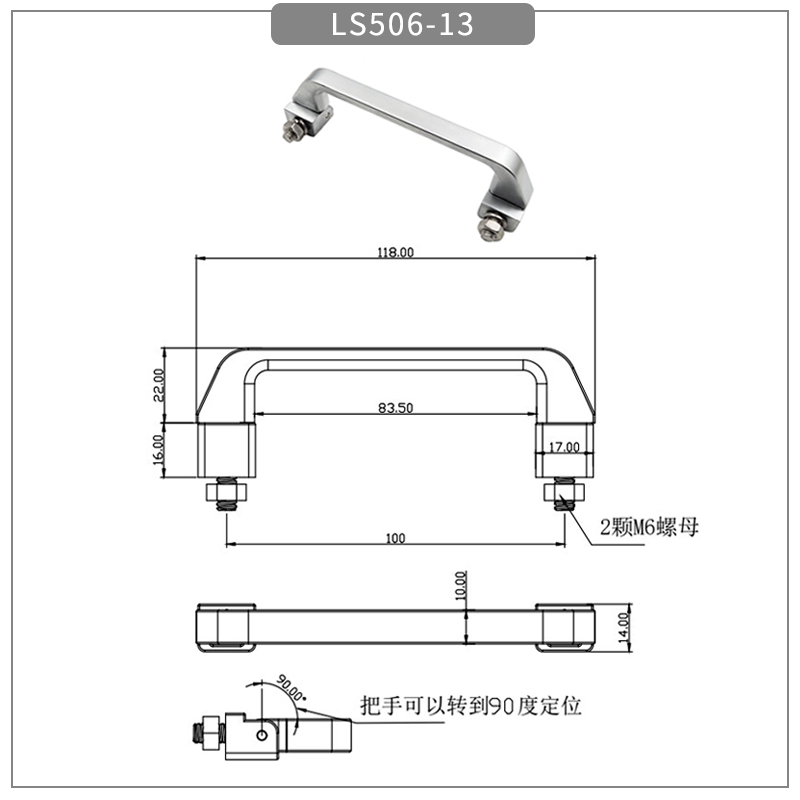

- Model: LS506-13

- Material:Zinc Alloy

- Finish:Matte

- Whether to support customization:Yes

Description

Product Features

Material and sturdiness: made of zinc alloy with thickening treatment, it has high density and hardness, high strength, sturdiness and durability.

Appearance design: simple and generous styling design, smooth lines, modern sense, able to match the appearance style of various equipment, furniture, and

Installation Convenience: the hole moment is 100mm, can adapt to different thickness of the door or equipment panel, easy and quick installation, can be firmly installed in the required position by screws and other fixings.

Scope of application

Industrial field: such as machine tools, welding machines, packaging machinery, medical machinery, electromechanical equipment, such as operating panels, access doors, toolboxes and other parts.

Electrical equipment: commonly used in cabinet doors of electrical equipment such as power distribution cabinets, switch cabinets, distribution boxes, control boxes, etc.,.

Industrial cabinets: applicable to the cabinet doors of industrial cabinets such as network cabinets, server cabinets, communication cabinets, etc.,.

Toolboxes and storage equipment: can be installed on the doors of various toolboxes, tool cabinets, file cabinets, storage boxes, etc., the

Other models:90 Degree Folding Movable Handle LS506-12

.png)

Five Frequently Asked Questions

Question 1: What to do if there is corrosion on the surface of zinc alloy handles LS506-13

Answer: Just a slight rust on the surface, you can use a mild detergent (such as a mixture of detergent and water) and gently wipe with a soft cloth to remove the surface dirt and rust.

Question 2: How to restore the luster of zinc alloy handle LS506-13 after oxidation?

Answer: For dull luster caused by mild oxidation, you can use metal polish to wipe it.

Question 3: How can I tell if the zinc alloy handle LS506-13 will be damaged by external force?

Answer: Check the bearing capacity parameters in the product manual to understand the maximum range of tension and pressure that the pull handle can withstand. During normal use, try to avoid applying forces that exceed this range.

Question 4: How to repair the surface treatment layer of zinc alloy handles LS506-13 after wear?

Answer: If the wear is light and there is only a small area of surface treatment layer peeling off locally, it can be repaired by using a paint refinishing pen of the same color as the original color of the handles.

Question 5: How to solve the adaptability problem encountered during the installation of zinc alloy handle LS506-13?

Answer: If the thickness of the door or equipment panel does not match the distance between the mounting holes of the handles, first check if there are suitable shims that can be used. Adjust the distance between the pull handle and the panel by adding shims so that the pull handle can be firmly installed

.png)

.png)

.png)

.png)

-150x150.png)

-150x150.png)

-150x150.png)

-150x150.png)

-150x150.png)

-768x768.png)

-768x768.png)