HTAN является одним из ведущих производителей промышленных петель, ручек и защелок в Китае.

-

+86 13720060320

-

julius@haitangs.com

Складные ручки для ящиков с инструментами: Повышение портативности и удобства

A toolbox is an essential companion for home maintenance, industrial operations, and outdoor work.

Сайт folding handle, as a core component, directly impacts the convenience and safety of use.

This article explores the function of folding handles, material selection, key design factors, and purchasing considerations to help you find the best solution for your toolbox needs.

Three Core Functions of a Folding Handle

1. Space-Saving Design

- Traditional fixed handles take up additional space, making storage and transport inconvenient.

- Folding handles reduce overall thickness by more than 30%, allowing for easy stacking and compact storage.

- Hinged or sliding folding mechanisms fully embed the handle into the toolbox, preventing collisions with other objects.

2. Enhanced Portability

- When unfolded, the handle provides a stable grip, ensuring balance even when carrying tools over 20kg.

- Ergonomic designs, such as curved grips, can reduce hand fatigue by up to 40% compared to straight handles.

3. Increased Safety

- Fixed handles can cause toolboxes to tip over during transport, potentially damaging tools.

- The retractable design of a folding handle prevents such accidents, enhancing overall safety.

Material Selection: Finding the Right Solution

1. Stainless Steel

- Advantages: Corrosion-resistant, strong load-bearing capacity (over 50kg).

- Best For: Industrial toolboxes, locomotive maintenance boxes, heavy equipment storage.

2. Aluminum Alloy

- Advantages: 30% lighter than stainless steel while maintaining a load-bearing capacity of up to 30kg.

- Best For: Mechanics and outdoor professionals requiring frequent transport.

3. Engineering Plastics

- Advantages: Cost-effective, good insulation properties.

- Disadvantages: Prone to aging with prolonged sun exposure.

- Best For: Electricians’ toolboxes, household maintenance kits, and laboratory equipment cases.

Key Design Considerations

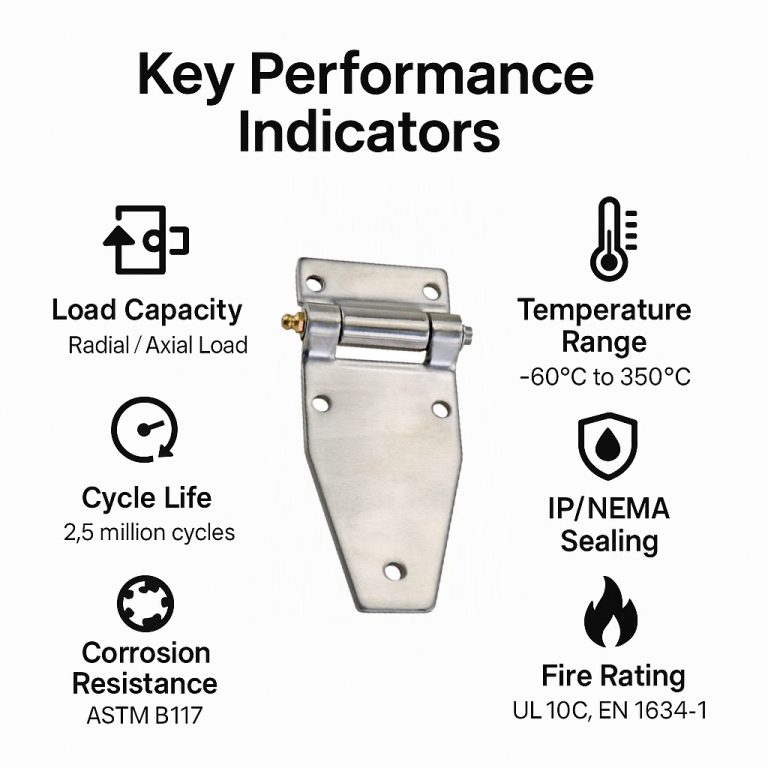

1. Load-Bearing Capacity

- A handle’s nominal load-bearing capacity should be at least 20% higher than the fully loaded toolbox weight.

- Example: A 15kg toolbox requires a handle with an 18kg minimum load capacity.

2. Долговечность

- Hinge Structure: Stainless steel bearings last 3 times longer than plastic hinges.

- Surface Treatment: Anodized aluminum or powder coating prevents rust and paint loss.

3. Installation Methods

- Screw fixing and embedded mounting are common options, ensuring stable installation and easy replacement.

4. Environmental Adaptability

- Depending on usage scenarios, ручки should offer waterproofing, dustproofing, or temperature resistance for optimal performance.

Installation and Maintenance Tips

Proper Installation to Prevent Hazards

- Обеспечить pre-installed holes in the toolbox align with the handle screws.

- Use anti-loosening washers (e.g., 3M VHB adhesive pads) for secure attachment.

- Тест smooth folding and unfolding after installation.

Regular Maintenance for Longevity

- Monthly Check: Inspect for loose screws and lubricate hinges as needed.

- Cleaning Advice: Wipe with a damp cloth and dry immediately to prevent rust.

Buying Guide: Choosing the Right Folding Handle

1. Consider Application-Specific Requirements

- Outdoor toolboxes: Opt for corrosion-resistant, UV-resistant, and waterproof materials (e.g., stainless steel, fiberglass-reinforced nylon).

- High-temperature environments: Avoid low heat-resistant plastics like ABS. Use POM or aluminum alloy instead.

- Wet environments (e.g., food processing, laboratories): Choose rust-resistant materials like stainless steel or plastic.

- Electrical toolboxes: Require insulating materials such as PA, POM, or rubber-coated handles.

2. Load-Bearing Capacity Categories

- Light Load (<10kg): Suitable for household and electronic toolboxes.

- Medium Load (10-50kg): Идеально подходит для industrial cabinets, medical trolleys, and standard toolboxes.

- Heavy Load (>50kg): Best for industrial toolboxes, locomotive maintenance, and heavy-duty equipment storage.

3. Manufacturer Selection

- Ensure compliance with industry standards (e.g., ISO 9001).

- Check if the manufacturer owns production facilities to avoid middlemen.

Вопросы и ответы

Q: Can a folding handle withstand frequent use?

A: High-quality handles are tested for 100,000 open/close cycles, lasting over 5 лет under normal use.

Q: How can I replace a damaged folding handle?

A: Most handles can be replaced by removing the screws. Refer to the toolbox instruction manual for guidance.

Q: Does a folding design reduce load-bearing strength?

A: No, a well-designed folding structure (e.g., double support arms) can evenly distribute pressure, sometimes offering better strength than fixed handles.

Q: What should I do if the handle gets stuck when folding?

A:

- Check for dust or foreign objects in the hinge.

- Clean with a soft cloth.

- If screws are too tight, slightly loosen them to ensure smooth operation without wobbling.

Заключение

Folding handles optimize space, enhance ergonomics, and improve safety, making them an essential component of any toolbox. Whether you need a heavy-duty industrial tool cabinet or a compact home toolkit, choosing the right folding handle significantly boosts efficiency.