HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

-

+86 13720060320

-

julius@haitangs.com

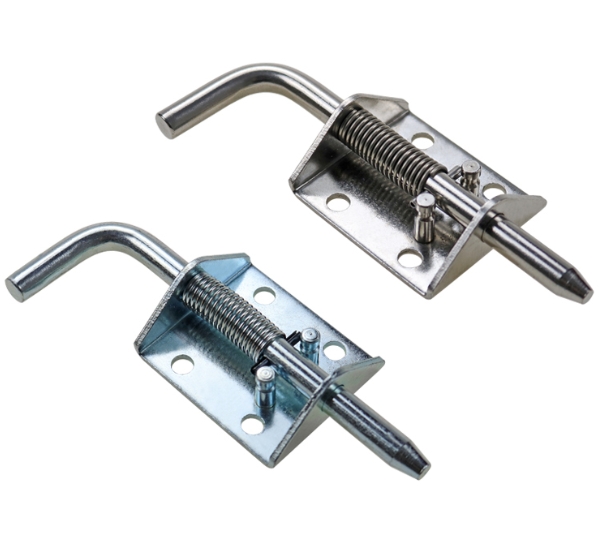

Top Benefits of Removable Spring Hinges for Flexible and Stable Applications

In modern industrial design and equipment manufacturing, removable spring hinges have gradually become the core component of all kinds of equipment hatches, shields and control panels due to their unique flexibility and durability. This article will comprehensively analyze the advantages of this product from the aspects of application scenarios, selection points, installation and maintenance, and help users choose the most suitable solution.

Why Removable Spring Hinges?

Removable spring hinges are specifically designed for industrial equipment, making them ideal for scenarios requiring frequent opening, maintenance, or replacement. These hinges address key challenges in industrial settings:

- Rapid Maintenance Requirements: Traditional welded hinges require time-consuming disassembly, while removable hinges reduce downtime significantly.

- Modular Design: Equipment in industries like medical and rail transport benefits from replaceable parts, with removable hinges supporting quick disassembly and assembly.

- Spring-Assisted Function: Balances door weight, enables automatic closing, and maintains opening angles, enhancing operational efficiency and safety.

Key Features for Choosing Removable Spring Hinges

Material Selection

- Stainless Steel: High corrosion resistance, suitable for marine equipment and outdoor cabinets.

- Zinc Alloy: Cost-effective, lightweight, ideal for medical equipment hatches and small distribution boxes.

- Engineering Plastics: Insulation, lightweight, commonly used in low-voltage electrical equipment and anti-static scenarios.

Installation and Compatibility

- Screw Fixing: Universal, compatible with standard holes.

- Snap-On Design: Tool-free installation, ideal for frequent maintenance.

- Door Thickness Compatibility: Ensure hinges match door panel thickness to prevent loosening.

Spring Torque and Opening Angle

- Torque Adjustment: High-quality hinges allow fine-tuning torque for doors of varying weights.

- Opening Angle Limitation: Built-in limiters fix doors at specific angles (e.g., 90°, 180°) to prevent over-opening.

Common Application Scenarios

Industrial Control Cabinets and Distribution Boxes

Removable spring hinges withstand frequent use, ensuring tight door closure and preventing dust ingress.

Medical Equipment Hatches

Modular design simplifies disinfection and part replacement, with stainless steel meeting hygiene standards.

Railway Train Inner Doors

High-load zinc alloy hinges resist vibrations, ensuring smooth door operation.

Special Vehicle Storage Compartments

Snap-on hinges enable quick disassembly, ideal for emergency maintenance in field operations.

Automated Machinery Guards

Adjustable torque hinges suit heavy-duty covers, with limit functions preventing mechanical interference.

Recommended Brands and Products

| Brand | Product Features | Application Scenario |

|---|---|---|

| HTAN | Stainless steel, adjustable torque, corrosion-resistant | Marine equipment, outdoor cabinets |

| Nanlin Hardware | Zinc alloy, snap-on design, lightweight | Medical equipment, small distribution boxes |

| Hettich | Engineering plastic, insulated, anti-static | Laboratory equipment, low-voltage electrical boxes |

Frequently Asked Questions

What is the difference between detachable hinges and traditional hinges?

Removable spring hinges allow quick disassembly without damaging the door structure, while traditional hinges require tools for removal.

Are spring hinges suitable for high-frequency opening?

Yes, spring hinges are ideal for high-frequency use, with lifespans exceeding 100,000 cycles when properly maintained.

How to judge the service life of hinges?

Look for sluggish spring rebound, loose hinge shafts, or increased noise as indicators for replacement.

Can spring hinges be adjusted for torque?

Premium models support torque adjustment via screws or knobs to accommodate varying door weights.

Recommendations for Proper Installation and Maintenance

Installation Precautions

- Align holes: Mark hinge positions on the door and frame to avoid misalignment.

- Uniform force: Install at least 2-3 sets of hinges to distribute door weight.

Maintenance Tips

- Regular lubrication: Apply silicone grease every 6 months to reduce wear.

- Check spring condition: Replace the spring assembly if resilience decreases.

Conclusion

Removable spring hinges are ideal for industrial, medical, and transportation applications, offering flexible disassembly, spring-assisted functionality, and high compatibility. When selecting hinges, prioritize material, torque adjustment, and installation method to match specific needs. Regular maintenance maximizes hinge lifespan and ensures equipment stability. By leveraging removable spring hinges, businesses can enhance operational efficiency, reduce maintenance costs, and achieve a balance of safety and flexibility.