HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Hinges, as the core component connecting door panels and frames, are widely used in doors, windows, furniture and industrial cabinets. In industrial application scenarios, this kind of hardware needs to cope with harsh working conditions: cabinet door daily high-frequency opening and closing operations, and at the same time need to withstand mechanical load, chemical corrosion and other multiple tests.

Concealed hinge vs Exposed hinge: basic definition

Concealed hinge

Definition: the hinge structure is completely invisible after installation, all parts are concealed inside the door.

Common scenarios: modern factory equipment cabinets, laboratory storage cabinets, metal cabinet doors.

Core advantages: clean appearance, dustproof, anti-corrosion.

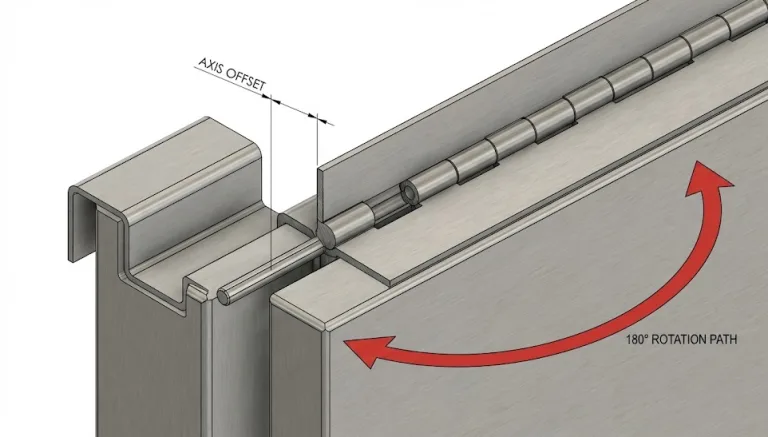

Exposed hinge

Definition: The hinge is exposed on the outside of the door plate and fixed directly by screws.

Common scenarios: warehouse tool cabinets, general file cabinets, metal cabinets.

Core advantages: fast installation, easy maintenance.

industrial cabinet door hinge comparison

Appearance design

Concealed hinge:

Completely concealed structure of the industrial cabinet door surface without any bumps or gaps, suitable for places that require simple design (such as clean room, medical equipment cabinets).

When the door is closed, the edges are flat and not easy to hook clothing or tools.

Exposed hinges:

Exposed metal pieces may affect the overall style of the cabinet door, but some retro industrial style designs will intentionally keep the exposed screws as decoration.

Installation and maintenance

Concealed hinge:

Professional tools are required to cut slots in the door panel and frame, and the error must be less than 1mm.

Suitable for factory pre-installation, later adjustment is difficult.

If it is damaged, it needs to be replaced as a whole, and the maintenance cost is high.

Surface mounted hinge:

Directly fixed with screws, workers can finish it with ordinary electric drill.

When the screws are loosened on one side, it can be repaired by tightening with a wrench.

Sealing and cleaning

Concealed hinge:

Do not destroy the cabinet door sealing tape, can effectively isolate dust, water vapor.

No exposed gaps, cleaning directly with a damp cloth to wipe the surface.

Exposed hinge:

Need to cut the adhesive strip when installing, there may be gaps after long-term use, resulting in dust entering the hinge interior.

Exposed hinge grooves are easy to accumulate oil, need to be cleaned regularly with a brush.

Load-bearing capacity and durability

Concealed hinge:

The use of high-strength steel, a single hinge can be load-bearing 20-50 kilograms.

But long-term frequent switching may lead to internal spring aging, need to be lubricated every 2-3 years maintenance.

Exposed hinge:

Simple structure, load-bearing stability of 10-30 kg.

In case of rust or deformation, single hinge can be replaced separately.

Security Comparison

Concealed hinge:

The fixing point cannot be seen outside, strong anti-prying.

Some models with self-closing function, to avoid accidental opening of the cabinet door.

Exposed hinge:

Exposed screws may be removed, less secure.

Anti-theft pins can be added to make up for the defects.

the cost analysis: how to save money on industrial scenes?

| Item | Concealed hinge | Exposed hinge |

|---|---|---|

| Single piece price | $15-50 | $3-15 |

| Installation labor cost | $20-50 per combination of pages | $5-10 per combination of pages |

| Maintenance cost | Annual average $50-100 group | Annual average $10-30/group |

| Applicable scenes | High-end customized cabinets, precision equipment | General warehouse cabinets, tool racks |

Conclusion:

Limited budget and low requirements for aesthetics, choose exposed hinge.

Long-term use or high-value equipment cabinets, give priority to Concealed hinges.

industrial cabinet door hinge selection of 3 tips

- Weight: Calculate the weight of the cabinet door. Single concealed hinge load recommended not to exceed 80% of the nominal value.

- Environment: Wet workshop selection of 304 stainless steel concealed hinge; high temperature environment to avoid plastic parts of the model.

- Opening and closing: Quality hinges should be smooth and noiseless when opening and closing. Suppliers can be asked to provide samples for testing.

Conclusion

In the field of industrial equipment, whether it is precision control cabinets, heavy duty tool cabinets or corrosive chemical storage systems, the scientific development of hinge selection strategy is the key to protect the performance of the cabinet. By accurately matching the load capacity, corrosion resistance and dynamic stress parameters of hinges, the structural integrity, protection and opening/closing stability of doors can be significantly optimized.