HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Adjustable one-way torque hinges provide torque in one direction (e.g., door opening or closing), while offering zero resistance in the opposite direction, ensuring exceptionally smooth operation.

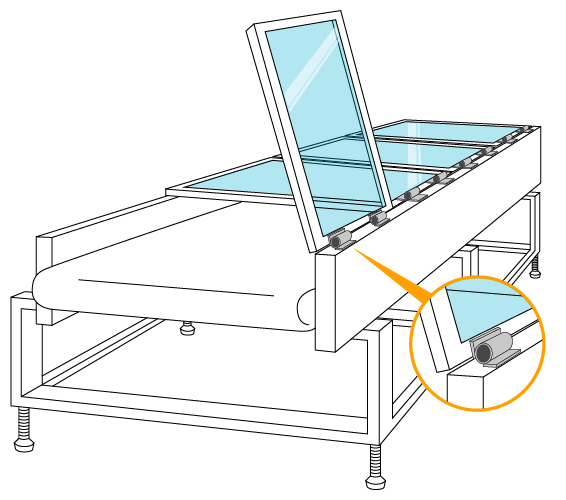

Our XG11-011 adjustable one-way torque hinge is used on conveyor belt covers

Our adjustable one-way torque hinge model XG11-011 is used in the cover switch section of the conveyor belt on a food production line. The primary purpose of the cover is to prevent dust and foreign objects from contaminating the product. By integrating the XG11-011 hinge, we helped the customer address several key challenges:

- Ensuring operational safety during cleaning and sweeping operations

- Allowing flexibility to accommodate hoods of various sizes

- Overcoming space limitations for on-site installation

Customer Challenges

- There was a risk of conveyor belt covers accidentally falling during cleaning operations in the food shop, posing a safety hazard.

- The solution needed to accommodate a wide range of conveyor belt covers in different sizes.

- It was also necessary to reduce the overall height of the conveyor belt cover support structure.

Product Information

- Manufacturer: HTAN

- Model: XG11-011

- Material: Zinc Alloy

- Finish: Matte

- Applications: Medical Equipment, FA Equipment, OA Equipment

- Torque Range: Adjustable from 0 to 2.0 N·m

- Customizable: Yes

Client Solutions

The XG11-011 hinge features a free-stop function that allows it to hover at any position and generates torque only in the closing direction.

The torque value is adjustable, and the adjustment can be conveniently performed even after installation.

Thanks to its ultra-compact structure, the XG11-011 hinge occupies minimal space and can effectively replace traditional support bars or gas springs.

One-Way Torque Hinges: Resolving the Safety vs. Operation Dilemma in Conveyor Belt Cleaning

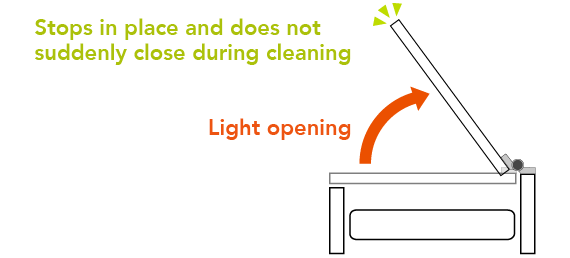

During conveyor belt cleaning, the flap must remain open. However, conventional mechanisms pose a safety risk due to the possibility of accidental flap closure. While traditional torque hinges support free positioning at any angle, their bidirectional torque design requires continuous force during opening, reducing ease of use.

The Solution

By utilizing the unidirectional torque hinge XG11-011, the design eliminates this issue through differentiated torque control:

- Closing Direction Torque (Adjustable 0–2 N·m):

→ Counteracts the flap’s gravity to ensure safe holding at any position

→ Prevents accidental cover drop during cleaning - Nearly Zero Torque in the Opening Direction:

→ Enables smooth, resistance-free opening with a gentle push

→ Balances ease of use and system safety, especially for heavy-duty flaps

Technical Advantages

This solution delivers value in multiple dimensions:

✓ Intrinsic Safety: Mechanical fall prevention replaces manual safeguards

✓ Human-Machine Optimization: Eliminates operational resistance and reduces worker fatigue

✓ High Compatibility: Adjustable torque accommodates various flap sizes

Adjustable Torque for Multi-Size Covers

Requirement: Conveyor belts need to accommodate covers of various sizes, and the torque must be adjusted accordingly.

Solution: XG11-011 adjustable torque hinge (0–2 N·m).

Advantages: One hinge fits multiple cover sizes; allows fine-tuning of operating force even after installation.

Hinge Application to Reduce Overall Machine Height

Requirement: Food equipment manufacturers often require reduced height for conveyor belt covers.

Pain Point: Limited space makes it difficult to use support rods or gas springs.

Solution: Replace traditional support structures with compact torque hinges.

Advantage: Significantly lowers the overall height of the machine.

Conclusion

The XG11-011 one-way adjustable torque hinge enables safe hovering of the cover at any position through adjustable closing-direction torque (0–2 N·m), effectively eliminating the risk of accidental falling during cleaning.

With near-zero torque in the opening direction, it ensures smooth, low-effort operation.

This hinge replaces traditional support bars or gas springs, significantly reducing overall equipment height.

A single hinge can adapt to cover plates of various sizes, and the torque remains adjustable even after installation — addressing the combined needs of safety protection, operational ease, and space optimization.