HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

-

+86 13720060320

-

julius@haitangs.com

How to Choose the Right Handles: A Guide to 4 Installation Methods

Handles are more than simple operating components; they significantly impact equipment safety, comfort, and durability. Different installation methods profoundly affect product usability, space utilization efficiency, and maintenance costs. For instance, flush-mounted handles sit level with the panel surface, effectively preventing accidental collisions; projecting handles protrude outward, offering a firm grip ideal for high-frequency operations. This article analyzes four mainstream handle installation methods (recessed, protruding, folding, and welded) to help you make informed decisions during design or selection.

Overview of General Classification and Comparison

Four Common Types of Handle Installation

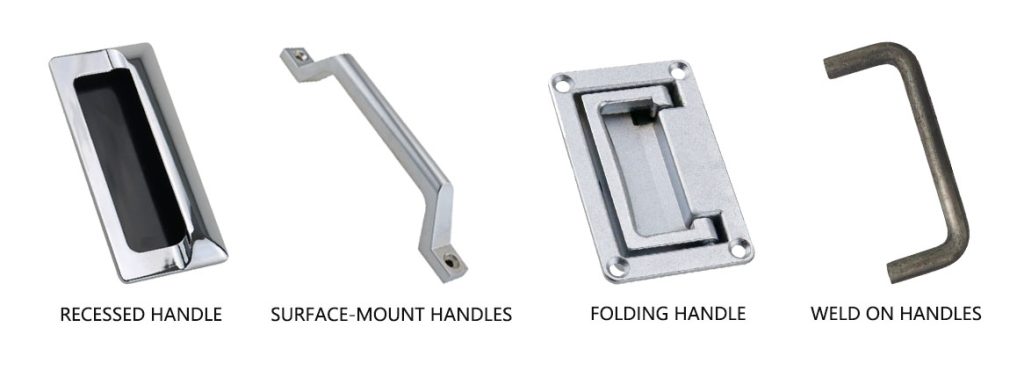

Before delving deeper, here’s an overview of the four common installation methods:

- Recessed Handles (Flush/Recessed/Cabinet handles): Installed flush with the panel surface, featuring no exposed handle for a compact structure.

- Protruding/Pull/Surface-mount handles: Extend beyond the panel surface, offering an intuitive grip and facilitating easy installation/replacement.

- Folding/Collapsible/Fold-down handles: Feature hinged or spring mechanisms for collapsible storage, folding flush with surfaces when not in use to save space.

- Weld-on/Heavy-duty/Industrial handles: Permanently bonded to the main metal structure via welding, offering extremely high load capacity but cannot be removed.

Common materials include stainless steel, aluminum alloy, carbon steel, and engineering plastics (such as nylon). The advantages, disadvantages, and typical applications of each handle type are as follows:

- Recessed handles: Advantages include space savings, collision avoidance, and dust/water resistance; disadvantage is requiring reaching into the recess for grip. Commonly used in cabinets, toolboxes, communication equipment, and other applications demanding high surface aesthetics.

- Protruding Handles: Advantages include easy operation and prominent positioning, suitable for high-frequency use; disadvantage is susceptibility to external impacts. Commonly found in industrial cabinets, mechanical door handles, and laboratory equipment environments.

- Folding Handles: Advantages include space-saving when folded, prevention of snagging, portability, and safety; disadvantages include complex structure and the need for high-quality hinge manufacturing. Used in space-constrained applications like military cases, tool cabinets, and portable devices.

- Welded Handles: Advantages include high load capacity, long lifespan, and extreme environment resistance; disadvantages are inability for quick replacement and high manufacturing costs. Used in heavy-duty applications like machinery, truck bodies, and steel containers.

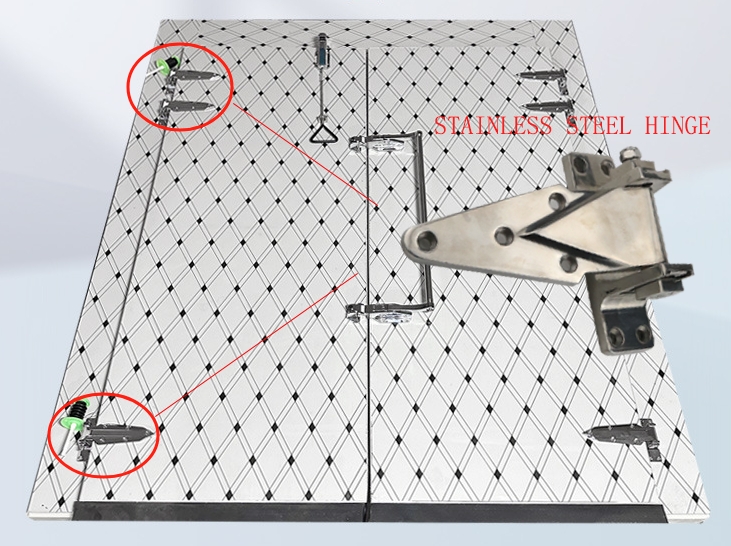

Flush Mount Handles

Flush-mounted (also known as recessed) handles install flush with the panel surface by cutting recesses into the panel for handle fixation. This design maximizes space utilization and reduces collision risks.

Key Advantages:

- Space-saving, prevents exposed collision points;

- Clean, unified appearance;

- Excellent sealing for dust and water resistance.

Typical Applications:

Commonly found in communication cabinets, toolboxes, instrument cabinets, or aerospace equipment requiring smooth surfaces and protection.

Design Considerations:

When designing the recess, account for handle dimensions and panel thickness to ensure sufficient structural integrity after installation. Reinforce the panel or select alternative handle types if the panel is too thin or the load is excessive.

Protruding Handles

Protruding handles extend beyond the panel surface, requiring no slot installation and typically securing directly with screws or bolts. Their visible grip eliminates the need to reach into recesses, enabling more intuitive and rapid operation.

Advantages:

- Easy operation, prominent positioning, simple installation/replacement;

- Suitable for high-frequency switching applications.

Potential Issues:

External protrusion makes handles susceptible to impact or snagging during handling or stacking, requiring additional protection.

Application Examples:

Suitable for industrial cabinets, machinery door handles, laboratory benches, and other scenarios involving heavy-load movement.

Folding Handles

Folding handles rotate or fold for storage, lying flush against the panel when not in use to save space. Common designs incorporate internal springs or locking mechanisms to automatically align and secure the handle against the panel when lowered, preventing rattling and noise.

Advantages:

- High space utilization, flush profile, prevents snagging;

- Excellent portability and safety.

Common design details:

Many products feature a 90° fold-and-lock design for stable handle fixation when lowered; spring-return mechanisms enable automatic reset after release.

Applications:

Primarily used in toolboxes, military cases, portable devices, and other space-constrained scenarios requiring flexible operation.

Weld-On Handles

Weld-on handles are permanently bonded to the main metal structure via welding, typically manufactured from high-strength steel. The welded construction provides exceptional rigidity and extremely high load-bearing capacity.

Advantages:

- High load capacity, vibration resistance, and extended service life;

- Suitable for extreme environments and heavy-duty applications.

Limitations:

- Cannot be quickly removed or replaced;

- Requires precise welding techniques that conform to industry standards such as AWS D1.1 for structural steel welding

Application Examples:

Commonly used in heavy machinery, transport vehicle bodies, and steel shipping containers where extremely high load-bearing capacity is required.

How to Select the Appropriate Handle Installation Type

When choosing handles, comprehensively consider the usage scenario, spatial layout, load-bearing requirements, operating frequency, and aesthetic demands. For instance:

- Outdoor or humid environments: Opt for corrosion-resistant handles meeting IP protection ratings. For more details on suitable materials and environmental performance, see [Guide to Industrial Handle Materials and Applications].

- High-frequency operation settings: Select handles with comfortable grip and easy installation.

Common scenarios and recommended types:

- Industrial Equipment: Heavy-duty machinery and transport containers use welded or reinforced protruding handles for sufficient load capacity.

- Cabinets / Electrical Boxes: For aesthetic and sealing priorities, choose recessed or foldable handles; for high-frequency use, opt for protruding handles.

- Toolboxes / Portable Cases: Foldable handles are typically chosen for limited space; welded or reinforced protruding handles are suitable for high load requirements.

- Furniture / Home Goods: Focusing on design aesthetics, concealed or sleek-profile handles are commonly used.

Ultimately, balance functionality, cost, and aesthetics based on specific needs to select the most suitable handle installation method.

FAQ

Q: Are recessed handles suitable for outdoor use?

A: Yes, but corrosion-resistant materials and proper sealing are essential. Meeting IP protection standards is critical—for example, IP67 rating provides complete dust protection and allows submersion up to 1 meter underwater, making it suitable for outdoor or humid environments.

Q: Can welded handles be replaced later?

A: Generally not recommended. Welded handles form an integral part of the main metal structure. Removal requires rewelding, which can damage the base material and compromise structural integrity.

Q: How durable are folding handles?

A: Durability depends on hinge and locking mechanism design. HTAN’s Folding Spring Toolbox Handle, foldable up to 90°, is made from high-quality stainless steel or alloy, providing exceptional strength and long-lasting durability, making it a reliable choice for any toolbox.

Q: How do I determine the load-bearing requirements for handles?

A: Calculate based on the equipment’s total weight and usage frequency, incorporating a safety margin. For example, if equipment weighs 50kg and is supported by two handles, each handle theoretically bears 25kg. Select handles rated for 30kg or higher. Typically, maintain a safety factor of at least 1.3 (a 30% margin) to accommodate dynamic or impact loads.

Q: Can handle colors and materials be customized?

A: Most manufacturers offer customization services. Customers can choose different surface treatments (e.g., anodizing, powder coating, or polishing), and materials and colors can also be tailored to requirements.

Conclusion

As seen, the four mounting methods each emphasize distinct structural and application priorities: flush-mounted handles prioritize compactness and aesthetics, protruding handles emphasize operational convenience, folding handles balance space utilization and flexibility, while welded handles are renowned for strength. Future design trends will increasingly focus on lightweighting, modularity, and eco-friendly materials to further optimize product performance and user experience. Regardless of whether you choose flush, protruding, folding, or weld-on types, the correct installation method is key to achieving efficient and safe design.

As a manufacturer specializing in industrial cabinet hardware, Anson LI Industrial Hardware brings over ten years of experience delivering high-quality, durable components. For inquiries or to discuss your project, please visit our Contact Us page.