HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Why do IP65/IP67 cabinets degrade in protection rating over time?

The root cause lies in a fundamental misjudgment of hinge function. For high-protection outdoor designs, hinges must be redefined not just as load-bearing pivots, but as “Sealing Compression Devices” capable of handling critical engineering realities:

- Countering Gasket Reaction: The hinge must prevent the rebound force of EPDM gaskets from pushing the door panel outward, which creates micro-leaks.

- Resisting Dynamic Loads: The hinge must withstand wind loads and frequent operation without developing pin wear that leads to door sag.

This guide moves beyond pure theory. It provides a quantifiable hinge selection strategy based on three dimensions: fit tolerances, material creep, and load calculations.

Deep Dive: The Engineering Implications of IP65 vs. IP67 for Hinges

Many engineers simply look up the definitions in the IEC 60529 standard, ignoring the specific requirements these standards translate to in terms of hardware mechanical performance.

Technical Breakdown of IP Ratings

IP65 (NEMA 4 Equivalent):

- Dust (6): Complete protection against dust ingress.

- Water (5): Protected against water jets from any direction (12.5 L/min at 3 meters).

- Hardware Implication: The hinge must resist micro-vibrations caused by water impact, and mounting holes must possess independent sealing capabilities.

IP67 (NEMA 6 Equivalent):

- Dust (6): Complete protection against dust ingress.

- Water (7): No water ingress when immersed in 1 meter of water for 30 minutes at standard temperature and pressure.

- Hardware Implication: This is a qualitative leap. The hinge must provide extremely high rigidity to ensure that, under water pressure, the compression of the sealing gasket remains consistent around the entire perimeter of the door.

Implied Engineering Metrics for Hinges

Based on our test data, to consistently meet the above standards, a hinge must satisfy the following three conditions:

- Uniform Sealing Pressure: The hinge must not only bear weight but also provide reverse tensile force. According to my observations, IP67 tests usually fail when gasket compression on the hinge side drops below 30%. The hinge must provide sufficient closing force to maintain this compression ratio.

- Tolerance Control: For IP67 applications, the gap between the door and the frame usually needs to be controlled within ±0.5mm. If the hinge’s Radial Play exceeds 0.2mm, the seal will fail.

- Structural Integrity: During high-pressure washdown tests (IP66/IP69K), if the hinge pin undergoes even micro-displacement, water will breach through the instantaneously created gap.

Core Selection Dimension I: Environmental Resistance & Material Science

Material selection errors are the primary cause of outdoor cabinet failure. I advise against relying solely on supplier brochures; instead, base decisions on ASTM or ISO standard data.

Corrosion Environment Classification & Recommendations

We categorize environments into two types with specific material recommendations:

Scenario A: Coastal & Marine Environments

- Primary Threat: Chloride ion corrosion, salt-laden sea breezes.

- Recommended Material: 316 Stainless Steel (UNS S31600)

- Rationale: 316 Stainless Steel contains 2-3% Molybdenum. According to ASTM G48 pitting tests, Molybdenum significantly improves resistance to chloride pitting.

- My Recommendation: For any project within 5 km (3 miles) of the coastline, or projects involving offshore wind power, the use of 316 grade is mandatory.

Scenario B: General Industrial & Urban Environments

- Primary Threat: Acid rain (sulfides), industrial exhaust, UV radiation.

- Cautionary Material: 304 Stainless Steel (UNS S30400)

- Risk: While 304 is cheaper, in my case library, 304 hinges in coastal industrial zones typically show obvious “Tea Staining” (red rust) within 6-12 months.

- Viable Option: Zinc Alloy + Surface Treatment

- Process Requirement: Must use high-grade black E-coat (Electrophoretic Deposition) or outdoor-grade powder coating.

- Test Standard: The coating must pass at least 500 hours of ASTM B117 salt spray testing.

A Warning on Engineering Plastics

- Material: Glass-Filled Nylon (PA6-GF30).

- Pros: Insulated, no corrosion risk.

- Potential Hazard: I find many engineers ignore “Creep.” Under long-term load and high temperatures, plastic hinges undergo permanent deformation, leading to door sag.

- Recommendation: Only use in scenarios where the door weight is less than 5kg and there are no strict security requirements.

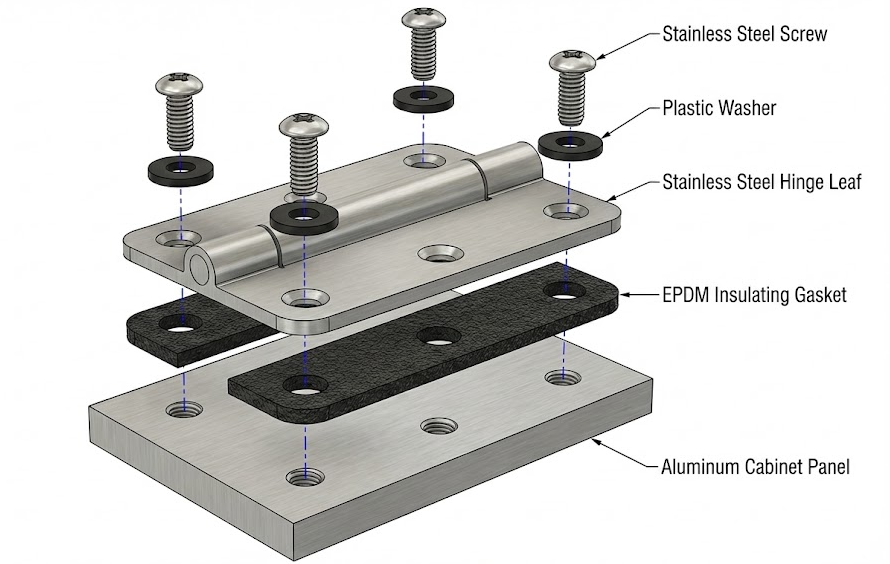

Prevention of Galvanic Corrosion

This is a detail often overlooked. When a stainless steel hinge is installed on an aluminum alloy cabinet in the presence of an electrolyte (salt water), the aluminum acts as the anode and corrodes rapidly.

- Solution: In design reviews, we mandate the addition of insulating gaskets (such as EPDM or PVC spacers) between dissimilar metals. This not only prevents galvanic corrosion but also aids in sealing the mounting holes.

Core Selection Dimension II: Hinge Structure & Sealing Performance

Structure dictates the upper limit of sealing capability. Different hinge types have vastly different impacts on IP ratings.

External Hinges

- Features: Installed on the exterior, supports 180° or 270° opening.

- IP Risk Points: Mounting screws usually need to penetrate the cabinet body. Every screw hole is a potential leak point.

- My Recommendation: If external hinges are necessary, select models with integrated O-ring sealed studs. Avoid using through-bolts with standard nuts unless paired with high-grade thread sealants.

Concealed / Internal Hinges

- Features: The hinge mechanism is located inside the sealed area or outside the gasket but covered by the door return.

- IP Advantage: This is the best choice for achieving IP65/IP67 because no holes are required on the external surface of the cabinet (or holes are outside the seal perimeter), maintaining enclosure integrity.

- Added Value: Possesses inherent Vandal-proof attributes, making them suitable for public utilities.

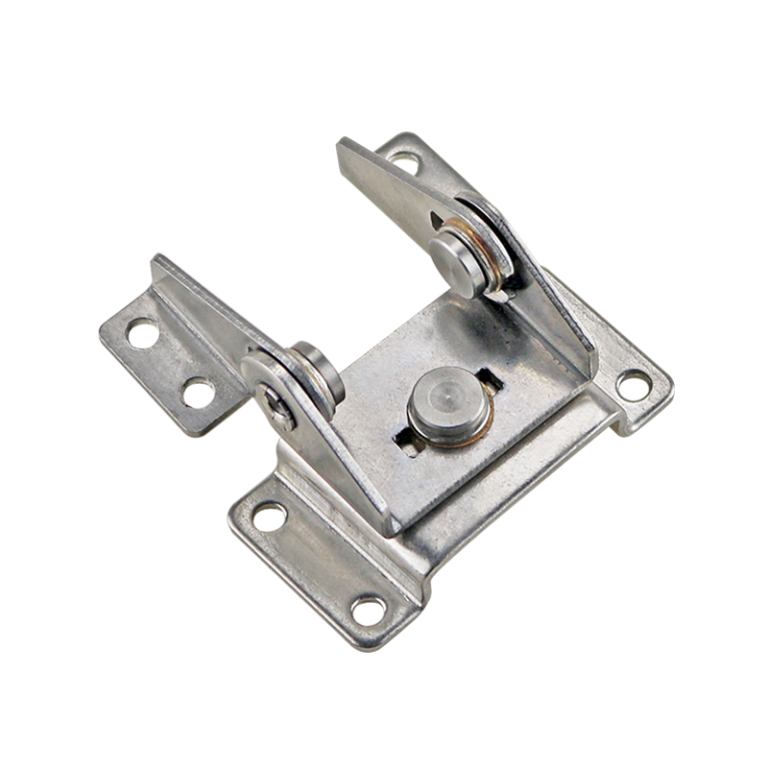

Adjustable Hinges — Strongly Recommended Over long-term maintenance, gaskets undergo “Compression Set” (per ISO 815). This means the gasket’s rebound force weakens over time.

- Function: Allows for micro-adjustment in the X/Y/Z axes.

- Engineering Value: When the gasket thins due to aging, maintenance personnel can adjust the hinge to re-tighten the door, restoring the 30%-50% compression rate.

- Conclusion: For IP66/IP67 cabinets with a design life exceeding 5 years, I consider adjustable hinges a standard configuration.

Mechanical Engineering Calculations: Load, Torque & Compression Force

Do not select based on intuition. We must use physics calculations to verify feasibility.

Door Load Calculation

Calculation isn’t just about the weight of the sheet metal door; it must include:

- Equipment mounted on the door (screens, fans, cabling).

- Safety Factor: Outdoor cabinets must account for Wind Load and ice accumulation. I recommend setting the Safety Factor at 2.5.

Gasket Reaction Force

This is the most common cause of hinge selection failure. Gaskets (especially foamed EPDM) generate massive reaction forces when compressed.

- Problem Description: If the hinge count or rigidity is insufficient, the gasket reaction force will push the door open, causing the middle of the door to bow, leading to seal failure at the center.

- Calculation Logic:

- Consult the gasket technical specs to get “Force per meter to compress.”

- Calculate total gasket length.

- Calculate total reaction force.

- My Rule: The sum of the locking force provided by hinges and latches must be > 1.5 times the total Gasket Reaction Force.

Hinge Spacing & Rigidity

To counter gasket reaction and door weight:

- Spacing Formula: The greater the distance between two hinges, the lower the door’s resistance to bowing.

- Reference Data: For cabinets exceeding 1000mm in height, I recommend using at least 3 hinges. The top hinge bears the most load (tensile stress) and should be reinforced.

Installation Design & Manufacturing Specs

Excellent hardware will fail if installed incorrectly.

Fastening Process Selection

Stud Welding:

- Pros: Does not penetrate the cabinet; completely eliminates leakage paths. This is the ideal process for high IP ratings.

- Cons: Difficult to replace if damaged.

Threaded Fastening:

- Spec: Must use flange nuts with integrated sealing capabilities.

- Anti-Loosening: Due to wind-induced vibration in outdoor equipment, screws loosen easily. You must use thread lockers (like Loctite 243) or Nylon insert lock nuts.

Layout & Vandal-Proof Design (IK Rating)

If the cabinet is in a public area, consider the IK10 Impact Protection standard (IEC 62262).

- Strategy: Select hinges with Non-removable pins.

- Fasteners: Externally visible screws must be security screws (Security Torx or Pin Hex).

Testing Verification & Maintenance Strategy

As a consultant, I do not believe in “theoretically feasible.” Every design must be verified through testing.

Verification Standards

Before mass production, your prototype should pass:

Salt Spray Test (ASTM B117):

- 304 SS: Pass 96 hours with no red rust.

- 316 SS: Pass 720 hours with no red rust.

- Zinc Alloy E-coat: Pass 480 hours with no base metal corrosion.

IP Protection Test (IEC 60529):

- Conduct actual rain or immersion testing. Afterward, use reactive test paper to check for even a single drop of water inside the cabinet.

Life Cycle Test:

- Perform at least 20,000 opening/closing cycles under full load. Measure hinge sagging after cycling. If sagging causes door displacement >1mm, it is considered a failure.

Maintenance Recommendations

Include the following clauses in the operation manual:

- Every 12 Months: Inspect hinge pins for metal dust (sign of wear).

- Lubrication: Use dry PTFE lubricant (Teflon). Avoid sticky grease, as it attracts dust and forms an abrasive paste that accelerates wear.

Conclusion

Selecting hinges for IP65/IP67 outdoor cabinets is not simply about purchasing hardware; it is a critical link in constructing a sealing system. Any cost savings on hinges will ultimately lead to expensive repairs for water-damaged equipment.

Quick Decision Checklist

Before finalizing the BOM, please confirm the following:

- Environment Match: Has 316 Stainless Steel been selected for coastal environments?

- Sealing Calculation: Is the number of hinges sufficient to overcome gasket rebound force?

- Galvanic Protection: Have insulating gaskets been added to dissimilar metal contact surfaces?

- Installation Sealing: Are screw holes sealed or is stud welding used?

- Adjustability: Have adjustable hinges been considered to compensate for gasket aging?

My Final Advice: In the early design phase (3D modeling stage), bring your industrial hardware supplier involved. Request detailed CAD models and load test reports, and conduct destructive rain testing during the sample phase. This is the lowest-cost path to project success.