HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In precision electromechanical system engineering, selecting robust industrial hinges in extreme temperatures is far more than choosing a simple connection component; it is a critical subsystem integrating motion control, load positioning, and vibration damping functions. From 5G base stations in Alaska to photovoltaic arrays at the equator, hinge systems face severe thermodynamic challenges.

Based on principles of Tribology, Rheology (The Society of Rheology), and Material Science, this article provides a deep analysis of the impact of extreme temperatures (-40°C to +200°C) on hinge performance. It further offers authoritative strategies for selection, design validation, and maintenance, referencing Telcordia GR-487 and IEC 60068 standards.

Introduction: Challenges for Industrial Hinges in Extreme Temperatures

In industrial environments, the definition of “extreme temperature” depends on the application scenario, but generally refers to operating conditions beyond the standard design range (-20°C to +60°C). Temperature fluctuations lead to two core failure dimensions:

- Transient Rheology: Temperature changes cause immediate fluctuations in the viscosity of the lubricating medium, triggering an exponential spike in starting torque.

- Steady-state Stress: Long-term thermal cycling results in material fatigue, stress relaxation, and permanent drift in fit tolerances.

For procurement managers and design engineers, understanding these physical mechanisms is key to avoiding Field Failure.

Tribology Analysis: Rheological Behavior of Lubricating Media

The “haptic feel” and motion control precision of a hinge essentially depend on the rheological stability of the damping grease across a wide temperature range.

Viscosity-Temperature Characteristics and Viscosity Index (VI)

The Viscosity Index (VI), calculated per ASTM D2270, is the core metric quantifying the magnitude of viscosity change with temperature.

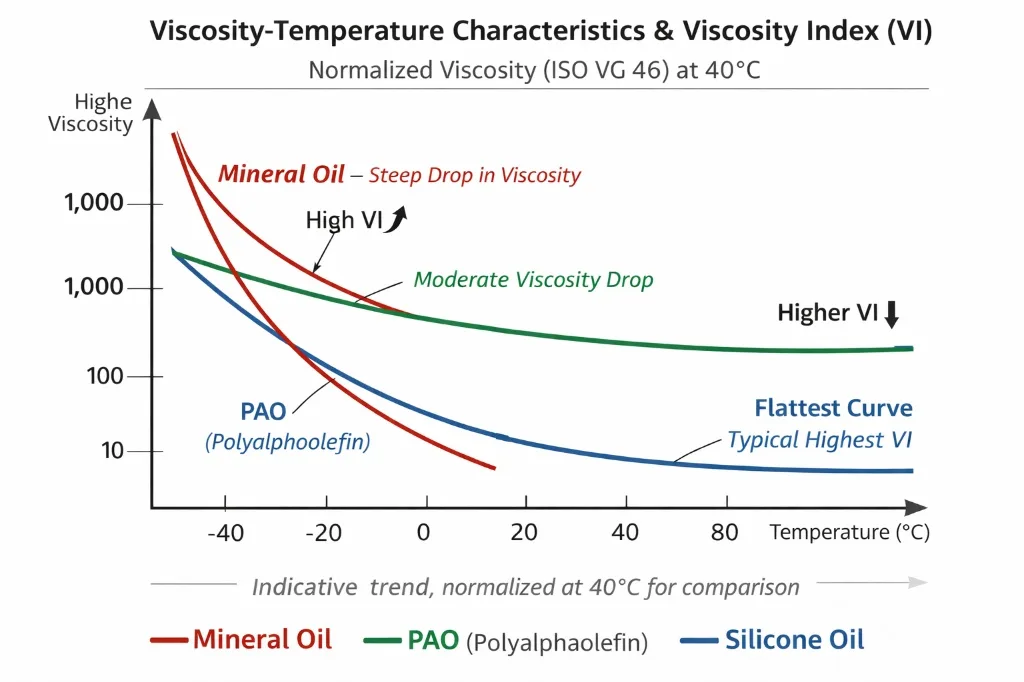

Figure 1: Idealized representation of Viscosity-Temperature characteristics based on ASTM D2270 principles. The curve illustrates the superior rheological stability of PAO (Polyalphaolefin) compared to Mineral Oils at low temperatures. Note: Schematic for comparative illustration only; exact viscosity values depend on specific grease formulations.

- Mineral Oils: VI values typically range from 95-105. Approaching 0°C, internal paraffin components begin to crystallize. As the temperature drops towards the Pour Point (ASTM D97), often around -20°C depending on the formulation, the fluid significantly loses flowability. This creates a “hydraulic lock” effect where starting torque can soar to 10 times that of room temperature, causing brittle fracture of plastic handles.

- Polyalphaolefin (PAO): VI values range from 135-160. PAO is free of impurities prone to crystallization, maintaining excellent flowability at -40°C. It offers good compatibility with engineering plastics like ABS and polycarbonate.

- Silicone Fluids: With VI values exceeding 300, silicone fluids exhibit the flattest viscosity-temperature curves. However, research indicates (NASA/OSTI) that silicone molecules have strong migration properties which pose a risk of contaminating electrical contacts. Caution is required in electronic equipment applications.

Hysteresis Effect: Starting Torque vs. Running Torque

In low-temperature environments, a distinction must be made between Starting Torque and Running Torque.

Using ASTM D1478/D4693 as test methods, measured results in certain grease formulations show starting torque at -40°C can be several times the running torque (reported values can exceed 6× depending on formulation and thickener structure).

Engineering Recommendation: The design Safety Factor must be based on the peak starting torque at low temperatures to prevent pin fracture.

Lubrication Failure Mechanisms at High Temperatures

When temperatures exceed +85°C, the primary risks shift to:

- Oil Separation: Evaluated via ASTM D6184, the base oil bleeds out of the thickener network. Excessive separation leads to drying and hardening of the grease, ultimately causing a loss of lubrication capability.

- Oxidation and Coking: Mineral oils easily oxidize at high temperatures, forming carbon deposits that increase wear.

Material Science: Thermal Expansion and Structural Integrity

A hinge is a composite system made of heterogeneous materials. Differences in thermophysical properties are the core factor leading to performance drift.

Stress Induced by Differential Thermal Expansion (CTE Mismatch)

The Coefficient of Linear Thermal Expansion (CTE) determines the rate at which dimensions change with temperature.

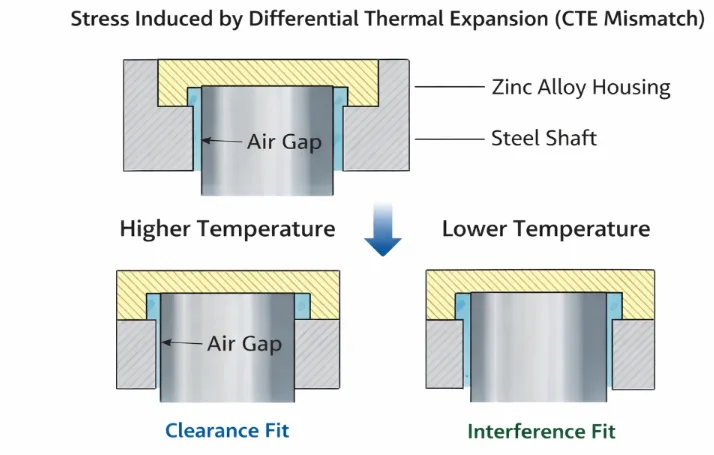

Figure 2: Schematic cross-section demonstrating the “Shrink-Fit” phenomenon caused by CTE Mismatch. At -40°C, the higher contraction rate of the Zinc housing eliminates the design clearance, creating significant radial stress on the steel shaft.

- Zinc Alloy (Zamak 3/5): ≈ 27 × 10-6/°C

- Stainless Steel (304/316): ≈ 17 × 10-6/°C

- Carbon Steel: ≈ 12 × 10-6/°C

Failure Model Analysis: Low Temperature (-40°C) causes the zinc housing to shrink approximately 2.5 times more than the steel pin. This leads to a drastic increase in the interference fit and a surge in normal force, highly likely leading to hinge Seizure.

Ductile-to-Brittle Transition (DBTT)

According to ASM Handbook Vol 1 data:

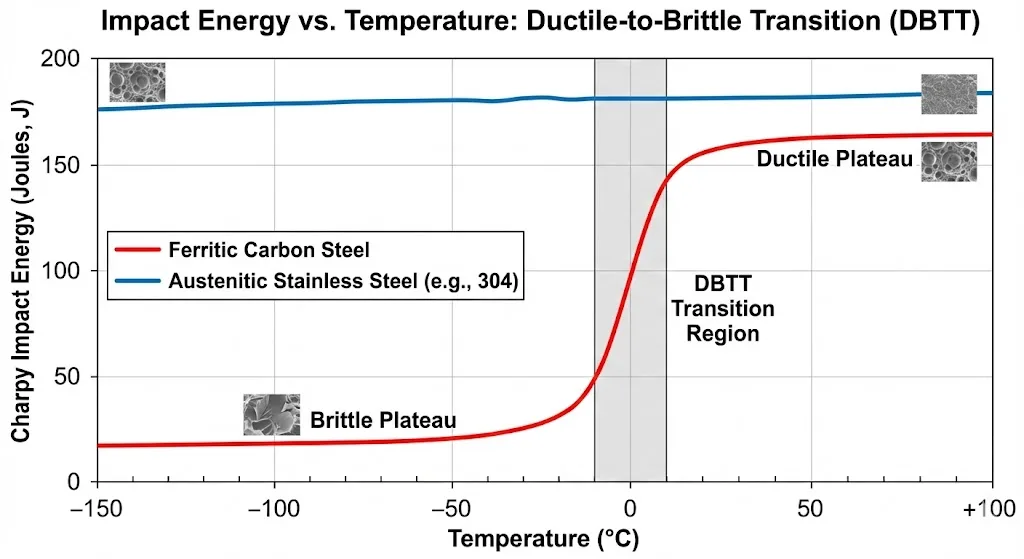

Figure 3: Typical Ductile-to-Brittle Transition (DBTT) behavior of Ferritic Carbon Steel versus the stable toughness of Austenitic Stainless Steel (300 Series). Note: General trend illustration; actual DBTT values vary by heat treatment and alloy composition.

- Carbon Steel: Exhibits a ductile-to-brittle transition temperature (DBTT) often around -20°C (dependent on heat treatment), where impact toughness drops precipitously.

- Austenitic Stainless Steel (300 Series): Possesses a Face-Centered Cubic (FCC) lattice structure, maintaining excellent toughness even in cryogenic environments down to -196°C.

Structural Design and Compensation Strategies

Constant Torque Structural Technology

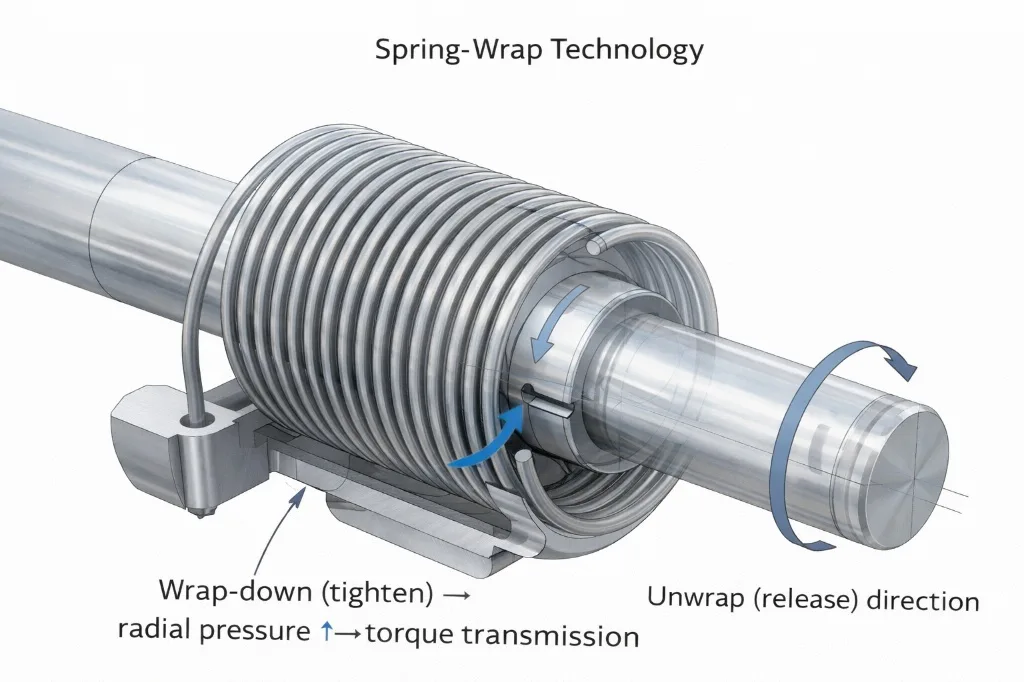

Figure 4: Structural mechanism of Spring-Wrap Technology. The “Wrap-down” action converts rotational motion into radial elastic deformation, allowing the spring to maintain consistent torque transmission despite minor thermal dimensional changes in the shaft.

- Spring-Wrap Technology: Uses a hardened steel spring wrapped tightly around the shaft. The spring structure allows for radial elastic deformation. When the shaft expands due to heat, the spring opens slightly. This design is insensitive to thermal expansion.

- Tolerance Compensation: In rigid fit designs, clearance must be reserved by calculating the Worst-case Tolerance Analysis.

Environmental Durability and Corrosion Protection

- Galvanic Corrosion: Countermeasure involves introducing insulating bushings (e.g., Acetal/Nylon) or applying passivation/coating treatments to the anodic metal.

- Telcordia GR-487 Standard: For outdoor telecommunications cabinets, hinges are required to pass wind-driven rain, salt spray (720+ hours), and impact resistance tests.

Validation Standards: How to Evaluate Suppliers

Reviewing the datasheet alone is insufficient. Procurement teams should require comprehensive validation reports. Critical Test Parameters should include:

- Sample Size (n): Minimum 5-10 units per batch to account for process capability (Cpk).

- Ramp Rates: Temperature change rates (e.g., 1°C/min vs 5°C/min) significantly affect thermal shock results.

- Instrumentation: Torque must be measured dynamically using calibrated load cells, not just “hand feel.”

| Test Item | Test Standard (Ref.) | Conditions | Pass Criteria |

| Temperature Cycling | IEC 60068-2-14 Nb | -40°C ↔ +85°C, Rate 1-3°C/min | No housing cracks, Torque drift < 20% |

| Low Temp Start-up | ASTM D1478 | -40°C dwell for 24 hours | Start torque < 3x Nominal, No seizure |

| Salt Spray | ASTM B117 / ISO 9227 | 720 Hours (Outdoor Grade Specification) | No Red Rust |

| High Temp Endurance | IEC 60068-2-2 | +85°C dwell for 240 hours | No oil leakage, torque decay within spec |

Field Failure Analysis & Case Studies

Real-world performance often reveals issues missed in lab tests. Below are anonymized case studies from Haitan’s engineering database.

| Scenario | 5G Base Station Enclosure (Arctic Deployment) |

| Failure Mode | Maintenance personnel reported “Door Seizure” at -35°C, resulting in handle breakage when forced. |

| Root Cause | Differential thermal contraction between the Aluminum housing and Steel pin eliminated the clearance. Grease viscosity spiked beyond design limits (Pour point was -25°C). |

| Solution | Switched to Austenitic Stainless Steel 316 for both pin and housing to match CTE. Upgraded to PAO-based grease (Pour point -60°C). |

| Result | Torque drift reduced to <15% at -40°C. Zero field failures in 24 months. |

Maintenance and Lifecycle Management

Even with the highest grade of engineering design, appropriate maintenance strategies are needed.

- Dynamic Lubrication Cycles: High temperatures accelerate grease degradation. A common engineering rule of thumb, derived from the Arrhenius Equation (IUPAC), suggests that the rate of oxidation roughly doubles for every 10°C rise in temperature. Therefore, lubrication intervals should be significantly shortened in high-temperature environments.

- Fastener Torque Re-verification: Expansion and contraction caused by temperature cycling can lead to a loss of bolt preload.

Conclusion

Hinge reliability under extreme temperatures is a systems engineering challenge involving tribology, material mechanics, and structural design. Successful engineering practice relies on precise definition of operating conditions and compensatory design for physical limitations.

Engineering Disclaimer

The information provided in this guide is for engineering reference and selection framework purposes only. Actual performance may vary based on load conditions, sealing methods, installation orientation, grease systems, and surface treatments. Users should conduct validation testing in their specific application environment. Haitan assumes no liability for failures resulting from improper selection without dedicated application review.

References

- Telcordia GR-487-CORE, “Generic Requirements for Electronic Equipment Cabinets”

- IEC 60068-2-14, “Environmental testing – Part 2-14: Tests – Test N: Change of temperature”

- IEC 60068-2-2, “Environmental testing – Part 2-2: Tests – Test B: Dry heat”

- ASTM D2270, “Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40°C and 100°C”

- ASTM D97, “Standard Test Method for Pour Point of Petroleum Products”

- ASTM D1478, “Standard Test Method for Low-Temperature Torque of Ball Bearing Grease”

- ASTM D6184, “Standard Test Method for Oil Separation from Lubricating Grease (Conical Sieve Method)”

- ISO 9227, “Corrosion tests in artificial atmospheres — Salt spray tests”

- ASM Handbook, Volume 1, “Properties and Selection: Irons, Steels, and High-Performance Alloys”

-768x768.png)