HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Introduction: Why might you be choosing the wrong hinge?

Torque hinges are not something that everyone is familiar with. Non-structural professionals in particular may be confused when they hear this term. Have you ever wondered why laptop screens can be held at any angle without falling? The answer is torque hinges. They are ubiquitous in daily life, but many people make mistakes when selecting them. Some use them as ordinary hinges, others choose the wrong torque value, and some install them in the wrong direction. These errors can cause equipment malfunctions and even safety hazards. Our team has seen many such cases, so we decided to write this article. Our goal is clear: to help you understand the key considerations when selecting torque hinges, so you can choose the right one the first time and avoid trouble.

What is a torque hinge? How does it differ from a regular hinge?

A torque hinge is a special type of hinge that provides torque. Torque is a force that allows a door panel or screen to stay in the position you want, preventing it from moving randomly. Ordinary hinges only rotate and do not control the angle. Torque hinges are different; they use internal friction or springs to create resistance, keeping the components securely in place.

For example, open your laptop and adjust the screen angle. It won’t close on its own or spring back. That’s the torque hinge at work. Laboratory equipment lids also commonly use them. When you open the lid, it stays in mid-air, making it easier to operate.

Don’t confuse them. Torque hinges are not support hinges or damping hinges. Support hinges bear weight, such as door hinges. Damping hinges slow down closing speed, like soft-close cabinet doors. The focus of torque hinges is to maintain angle. Be clear about this when selecting, to avoid mistakes.

🔧 Tip: Don’t use torque hinges as ordinary hinges—their functions are completely different!

How do I know if my equipment needs a hinge that “maintains the angle”?

Before purchasing a torque hinge, ask yourself a few questions. Does your equipment have components that need to stay at a specific angle? Does it need to hold the angle on its own after you let go? Do users need to easily adjust the angle? If the answer is “yes,” then you need a torque hinge.

Consider real-world scenarios. The screen on a medical cart needs to be adjusted to different angles for doctors and nurses to view. A torque hinge keeps the screen securely in place without additional support. The same applies to the cover of an industrial control box. Technicians need to open the cover for maintenance, and it must stay suspended in mid-air without dropping and hitting their hands.

We’ve summarized the criteria:

- The component must stay at any angle.

- No additional support is needed.

- Users must be able to adjust it easily.

If these criteria are met, your equipment is suitable for a torque hinge. Don’t hesitate when selecting one—consider it directly.

The video demonstrates the application of torque hinges on a cover panel

Single-direction vs. double-direction torque: Choosing the wrong one is a waste?

One-Way Torque Hinges

Torque hinges come in two types: one-way and two-way. Choosing the wrong type renders the installation ineffective.

one-way torque hinges only provide resistance in one direction. Typically, torque is applied when opening, with minimal resistance when closing. They are suitable for equipment requiring quick closure. two-way torque hinges operate differently. Torque is applied during both opening and closing, allowing the door panel to stop at any angle. They are ideal for scenarios requiring full control throughout the process.

A real-world example: A laboratory equipment lid used a one-way torque hinge, but it was installed in the wrong direction. After opening, the lid sprang back and directly hit the operator’s hand. Where did the problem lie? The opening and closing requirements were not understood. When selecting a torque hinge, first confirm how the equipment moves. Whether it’s one-way or two-way, the correct type must be chosen.

📌 Pitfall avoidance guide: Before placing an order, confirm the opening and closing direction with the supplier—don’t choose based on intuition!

What torque value do I need? Is there an empirical formula?

Torque value is the core consideration when selecting a torque hinge. If the value is incorrect, the equipment will either not move or be unstable.

There is a simple formula: Torque = Force × Distance. Force is the gravitational force of the door panel, and distance is the length from the hinge to the center of gravity. Calculating this will determine the required torque value.

For example, if the door panel weighs 5 kilograms and the center of gravity is 0.3 meters from the hinge, first convert the weight into gravitational force: 5 × 9.8 = 49 Newtons. The torque is 49 × 0.3 = 14.7 Newton-meters (N·m). If two hinges are installed, each will bear 7.35 N·m. When selecting, look for models within this range.

Don’t make a mistake in your calculations. The shape of the door panel and the installation location will affect the results. It is best to verify with the supplier. They have experience and can help you adjust it. If the torque is too high, the door panel will not move. If the torque is too low, the door panel will fall off. Choosing the right value will solve the key problem.

🧠 Reminder: Test the weight of the door by hand and estimate it; don’t just guess.

Is the installation direction important? Why do spring hinges sometimes fail to spring back?

If the torque hinge is installed incorrectly, it will be ineffective. Especially for spring-type torque hinges, incorrect direction renders them useless.

This issue commonly occurs with control cabinet doors. If the spring-type torque hinge is installed incorrectly, the door will not spring back after opening or will not close properly. The reason is simple. The design specifies a fixed direction, and installing it incorrectly prevents the spring from exerting force. When purchasing, check the manual; hinges have arrows or markings. Install according to the instructions, and there will be no issues.

There is another critical issue. The spring force must match the door weight. If the force is insufficient, the door won’t close. If the force is too strong, it will slam shut and cause damage. Test it before installation to ensure it’s appropriate.

We have seen too many cases of incorrect installation. Do not take it lightly. After purchasing torque hinges, installation is the critical step that determines success or failure.

Which industries most commonly use torque hinges?

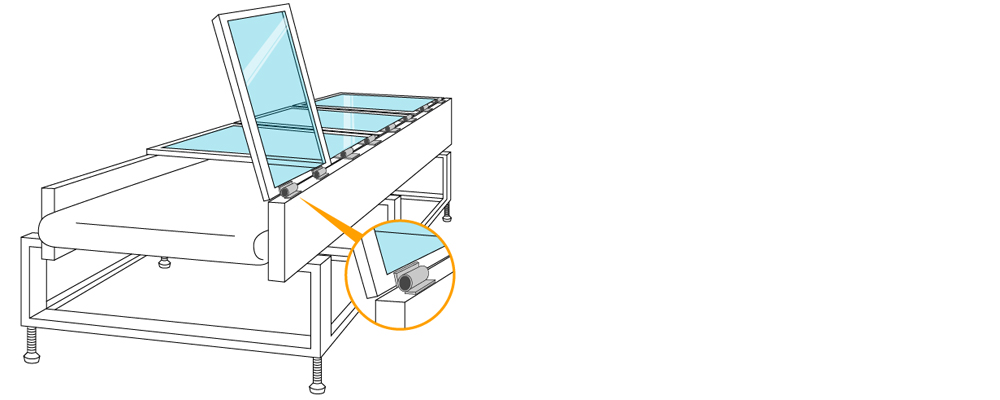

Image source: Sugatsune

Torque hinges have a wide range of applications and are indispensable in many industries.

They are widely used in medical equipment. Mobile cart screens need to be adjusted to different angles, and torque hinges keep them securely in place. The same applies to instrument covers, which stay open without falling down. Industrial control systems are no exception. Control panel covers must remain fixed in place when technicians perform maintenance. They are even more common in laboratories. Test chamber lids can be held in mid-air, making it easier for experimenters to operate.

They are also used in transportation. Vehicle control panel screens need to be adjusted to accommodate different drivers. The telecommunications industry also benefits. Cabinet doors can be opened, allowing maintenance personnel to work safely. Torque hinges enhance efficiency and safety.

Consider your industry when selecting. When the application is right, torque hinges prove invaluable.

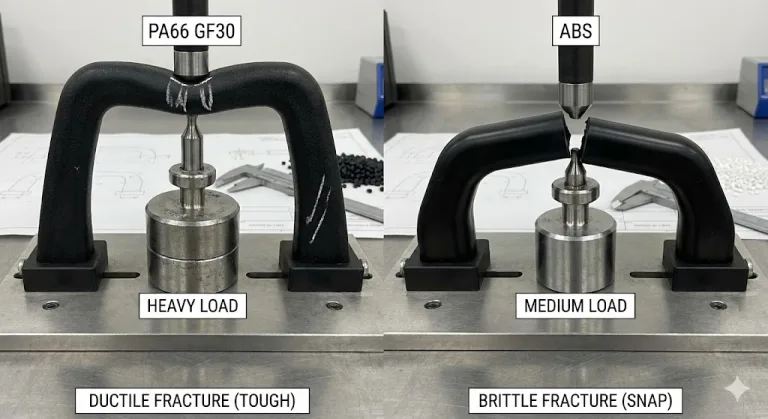

Plastic hinges vs. stainless steel torque hinges: Which material should you choose?

Material selection is critical when choosing torque hinges. Plastic and stainless steel each have their advantages and disadvantages.

Plastic torque hinges are lightweight, cost-effective, and corrosion-resistant. They are suitable for light-duty applications, such as small laboratory covers. Stainless steel torque hinges are sturdy and can support heavy doors. They are best for outdoor use, as they are corrosion-resistant and have a long lifespan.

Let’s compare:

| Feature | Plastic | Stainless Steel |

|---|---|---|

| Strength | Low | High |

| Price | Low | High |

| Lifespan | Moderate | Long |

| Suitable Env. | Indoor, light load | Outdoor, heavy load |

The environment must also be considered. For humid or corrosive environments, choose 304 or 316 stainless steel. When selecting, don’t just look at the price; suitability is more important.

📌 Pitfall avoidance guide: In corrosive environments, don’t use plastic; stainless steel is more reliable.

Are torque-adjustable hinges better? What equipment are they suitable for?

Torque-adjustable hinges can modify the torque value, which sounds advanced. Are they really useful?

We believe they are suitable for R&D. During the testing phase, when torque values are uncertain, they can be adjusted at any time. For example, the XG11-077 allows torque adjustment from 1.0 to 5.0 N·m. This eliminates the hassle of replacing hinges. They are also suitable for equipment with variable functions. When requirements change, simply adjust the torque.

However, do not use them indiscriminately. Adjustments must be made according to the instructions; otherwise, they may be damaged, rendering them useless. Once the torque is fixed for the final product, switching to a standard model is more cost-effective. When selecting, consider your needs and don’t blindly pursue adjustability.

Will the torque loosen over time? What factors affect its lifespan?

Customers often ask: Will the torque hinge loosen over time? The answer is clear: High-quality hinges won’t loosen easily.

Lifespan depends on the number of rotations. A good hinge can withstand 10,000 openings and closings while maintaining stable torque. Material plays a significant role. Stainless steel is more durable than plastic. Internal structure is also critical. Well-designed friction plates and springs extend lifespan. Lubrication also helps reduce wear.

When selecting, choose reputable brands. With proper installation and maintenance, torque hinges can last for years. Don’t worry—if used correctly, they won’t loosen.

Recommended models (including specifications) for beginners

First-time purchaser of torque hinges? We recommend the following models:

- HL127

Torque: 0.1–1.5 N·m

Material: PA6

Dimensions: 72mm × 56mm

Application: Medical Equipment, Instrument Equipment, Control Cabinets - SK2-2

Torque: 0–6.0 N·m

Material: Stainless steel

Dimensions: 90mm × 82.5mm

Application: office equipment, furniture, control panels, etc. - DP046

Torque: 0.7-3.0 N·m

Material: Stainless steel

Dimensions: 76mm × 14mm

Application: lighting equipment, medical equipment

📌 Compare your requirements when selecting. With clear parameters, selection is straightforward. If you have any questions, consult technical support; do not experiment on your own.

Conclusion: Choosing the right torque hinge saves three years of maintenance hassle

Choosing the right torque hinge ensures smooth operation of equipment and reduces maintenance costs. A single mistake could result in three years of repairs. We hope that after reviewing these 10 key questions, you can avoid common pitfalls. Selecting a torque hinge is no small matter; caution is advisable.

If you have any questions, contact technical support. They can provide recommendations and even send samples for testing. Contact us—li’t let choosing the wrong hinge hold you back.