HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Industrial cabinet door stainless steel hinges are crucial, corrosion-resistant alloy material, suitable for high-frequency switching and heavy-duty conditions. There are a variety of types, the key features cover corrosion resistance, load capacity, etc., the selection needs to take into account a number of factors, installation and maintenance also have skills, this article for you to analyze in detail.

Understanding stainless steel hinges for industrial cabinet doors

Stainless steel hinges for industrial cabinet doors are made of corrosion-resistant alloys designed for high-frequency switching and heavy-duty conditions.

The chromium oxide layer resists chemical attack and the high-strength structure supports heavy-duty doors.

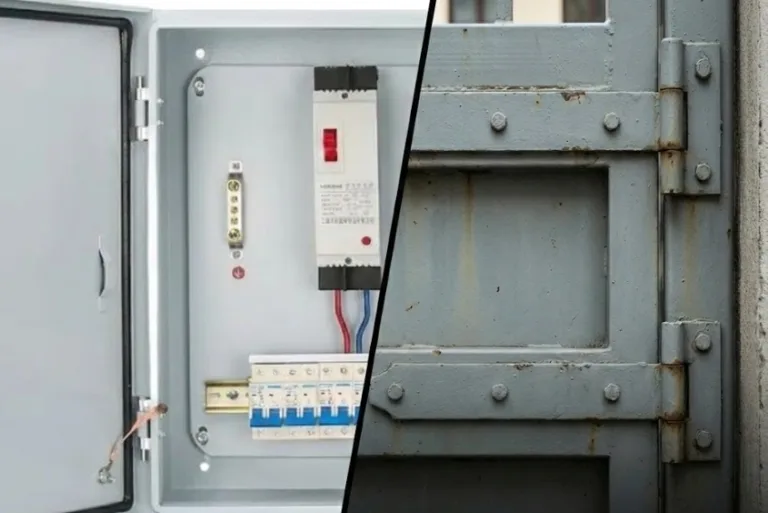

Suitable for electrical cabinets, communication base stations and other industrial scenarios that require impact resistance and weather resistance.

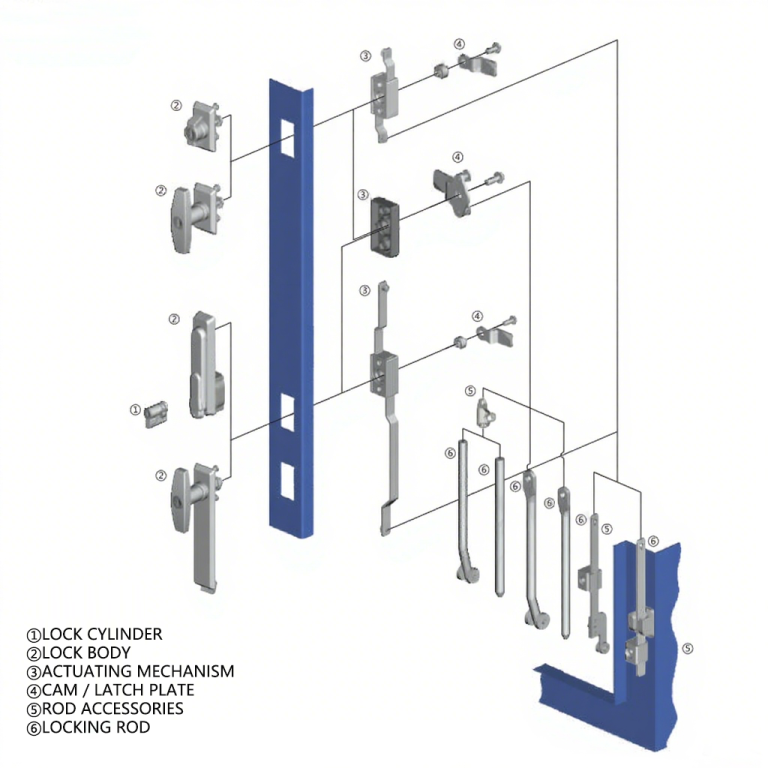

Types of stainless steel hinges for industrial cabinet doors

According to different needs, stainless steel hinges are divided into the following types:

Butt hinge

Docking type stainless steel hinges adopt pin-connected bimetal structure, which has the advantages of both installation stability and load-bearing.

Designed for power equipment, heavy machinery and other scenes that need to withstand constant vibration, through the simplification of the structure to enhance the reliability of the hinge in extreme working conditions.

Continuous hinge (piano hinge)

Features:

The hinge covers the entire length of the door frame, dispersing the pressure and preventing the door from sagging.

Applicable scenarios:

long cabinet doors that require even load bearing, such as server cabinets.

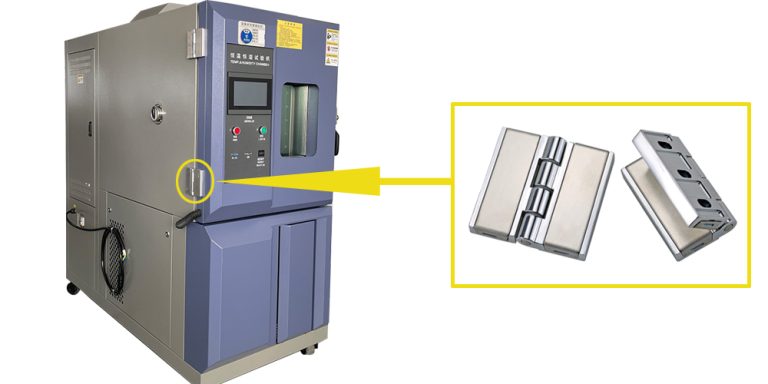

Concealed Hinges

Features:

concealed design, the hinge structure is not visible from the outside, enhancing security.

Application Scenario:

Medical equipment cabinets or utility cabinets with high aesthetic requirements.

Removable Hinges

Features:

Quickly separates the door from the cabinet for easy maintenance of internal equipment.

Applicable scenarios:

industrial control cabinets or laboratory equipment that require frequent maintenance.

Strap Hinges

Features:

Fixed by metal straps to provide additional support, suitable for oversized doors.

Scenario:

Large industrial cabinets or outdoor communication base stations.

Selection suggestions:

Match according to the weight of the cabinet door (e.g. invisible hinges for light-duty doors, strap hinges for heavy-duty doors) and switching frequency (removable design is recommended for high-frequency use).

Key features of industrial stainless steel hinges

Corrosion resistance

304 Stainless Steel: Suitable for regular industrial scenarios (workshops, dry areas);

316 stainless steel: chemical plants, coastal and other highly corrosive environments.

Load capacity:

Load-bearing value needs to exceed 50% of the door weight (Example: 10kg door body choose ≥15kg hinge), reserved for safety redundancy.

IP protection level:

IP65 dustproof and spray resistant, suitable for outdoor;

IP67 short-time immersion resistance, suitable for cleaning workshop.

Adjustability:

Three-dimensional micro-adjustable hinges can correct installation deviation, realize seamless closure of door and cabinet, and improve sealing.

Soft-Close Function

Reduces the impact of closing the door by built-in damping, reduces noise and prolongs the life of the hinges.

How to choose stainless steel hinges for industrial cabinet doors

Evaluate environmental conditions

Wet or chemical-exposed areas (e.g. plating shops) require 316 stainless steel.

High temperature environment (such as boiler room) need to confirm the temperature range of the hinge (usually stainless steel can withstand more than 400 ° C).

Matching size and weight

Before installation, you need to accurately determine the thickness of the cabinet door and self-weight data, and based on the results of the measurement to verify that the hinge product specifications of the screw hole distance and load parameters are appropriate.

Maintenance Requirements

For cabinets that require frequent maintenance, prefer removable hinges to minimize maintenance time.

Budget Balance

316 stainless steel costs about 30% more than 304, but reduces long-term replacement costs in harsh environments.

Stainless Steel Hinge Installation Tips

Tool Preparation

Electric drill, screwdriver, level, screws (stainless steel screws are recommended to prevent rust).

Installation Steps

Mark the hinge position and make sure both sides are symmetrical.

Pre-drill the holes to prevent the plate from cracking.

After fixing the hinges, check the door alignment with a level.

Avoid Mistakes

Mistake:

Using common iron screws, which leads to rust spreading to the hinges.

Mistake:

Neglecting the installation of sealing rubber ring reduces the IP protection.

Industrial application scenarios of stainless steel hinges

Manufacturing: Protecting the internal wiring of electrical control cabinets.

Outdoor cabinets: Resist rain and UV rays, such as traffic signal boxes.

Food processing plants: easy-to-clean design meets sanitary standards.

Marine facilities: 316 stainless steel to resist salt spray corrosion.

Maintenance and care

Monthly wet cloth cleaning, quarterly silicone grease lubrication; high-frequency use of six-month wear and tear assessment, loose, abnormal noise or rust spots instant replacement.

FAQ

Q1: What is the best grade of stainless steel for industrial cabinet hinges?

Most of the scenes choose 304 stainless steel; high corrosion environment choose 316 stainless steel.

Q2: Can stainless steel hinges be used for outdoor cabinets?

Yes, you need to choose IP65 or above grade and match with 316 material.

Q3:How to judge whether the hinge has IP65 protection?

Check the product label or manual, IP65 will be clearly marked.

Q4: Are invisible hinges suitable for heavy doors?

No. Invisible hinges have a lower load capacity and are recommended for small to medium sized doors.

Q5: How often do industrial hinges need to be maintained?

Every six months for normal environment, quarterly for high humidity or high frequency usage environment.

Conclusion

Industrial cabinet door hinge selection needs to pay attention to three points: according to the load-bearing hinge or hidden structure; environmental corrosivity is high when the priority of 316L stainless steel; combined with the thickness of the door plate, open and close the angle of mechanical analysis to ensure stability. Chemical workshop and other high-frequency scenarios choose heavy-duty stainless steel hinges with self-lubricating bearings, which can reduce the number of maintenance by more than 50%, ensure the sealing and adapt to the temperature range of -40 ℃ to 120 ℃, to enhance the reliability of the equipment and save long-term costs.

-768x768.png)