HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Heavy-duty stainless steel butt hinges are corrosion-resistant, load-bearing, and the preferred choice for outdoor industrial and corrosive environments, outperforming rust-prone carbon steel/brass to provide years of solid support for heavy-duty structures.

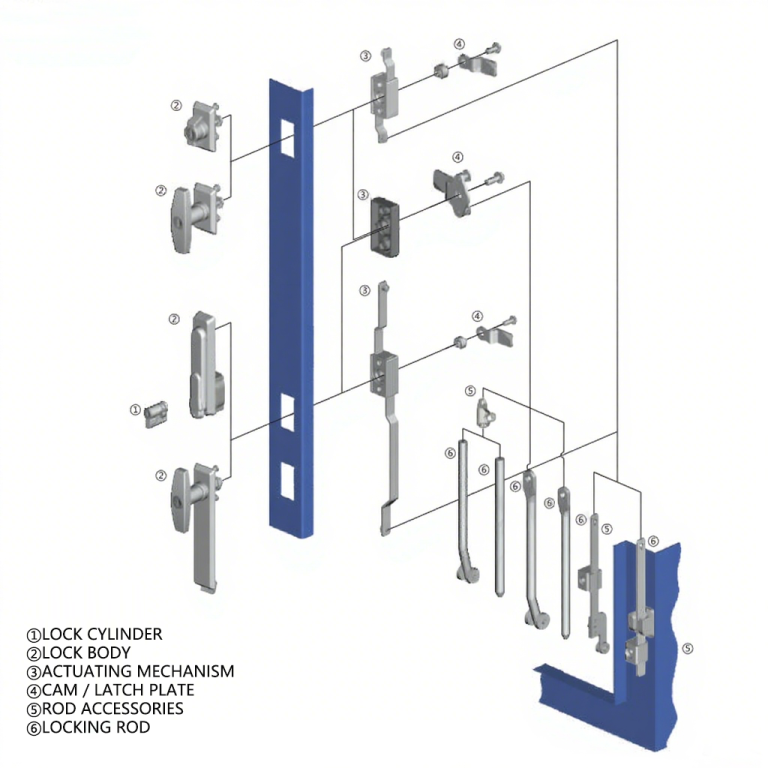

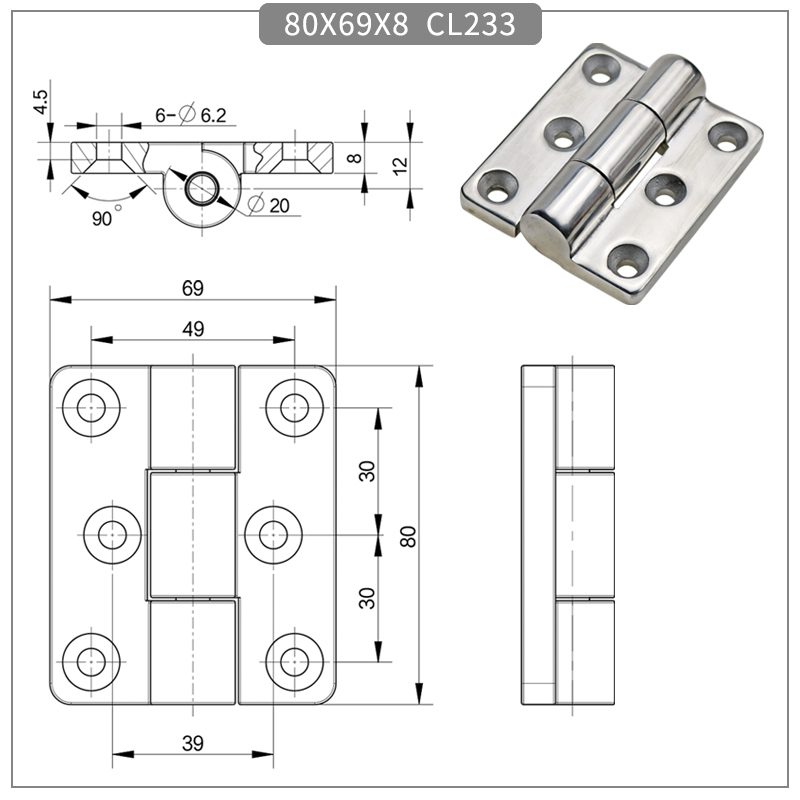

What is a butt hinge? Definition and Structure

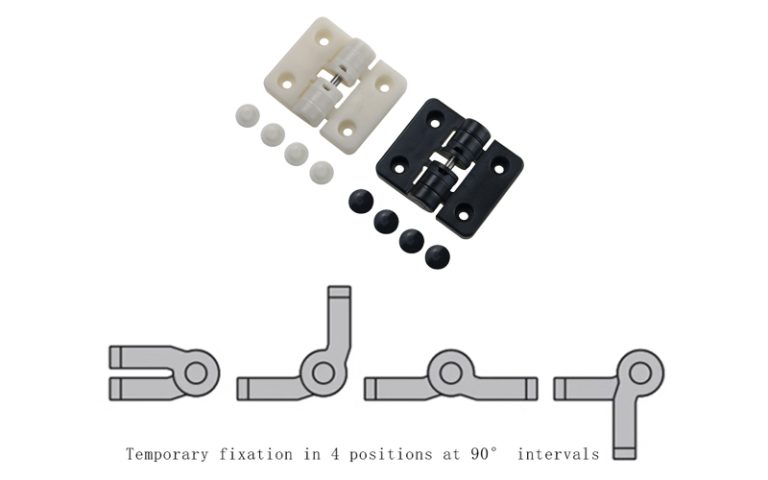

Butt hinges consist of two metal blades connected by a pin, which is fixed to the door and frame and which provides the rotating function. The construction is simple but must withstand long-term wear.

Comparison of materials

Brass: beautiful but low strength, suitable for light decorative doors.

Carbon steel: strong load bearing but easy to rust, need surface plating treatment.

Stainless steel: best balance of corrosion resistance and strength, especially suitable for industrial scenes.

Stainless steel commonly used models

304 stainless steel is the common model, suitable for daily humid and weak acid environment.

316 stainless steel adds molybdenum to enhance the resistance to salt spray and chemical corrosion, suitable for coastal, chemical zones and other harsh environments.

Why choose heavy duty stainless steel butt hinges?

Strong load-bearing capacity: a single pair of hinges can bear 20-200 kilograms, suitable for metal doors and cabinet doors.

Strong corrosion resistance: long-term exposure to rainwater, salt spray still does not rust.

Long service life: wear-resistant design reduces maintenance frequency and replacement cost.

Appearance adaptability: brushed or mirror surface treatment, in line with industrial aesthetics needs.

Comparison Table: Stainless Steel vs Carbon Steel vs Brass

| Properties | 304 Stainless Steel | Q235 Carbon Steel | H59 Brass |

|---|---|---|---|

| Material Class | Austenitic stainless steel (chromium-nickel containing) | Ordinary mild steel | Zinc-containing brass (59% copper, 40% zinc) |

| Corrosion resistance | ★★★★☆ Excellent, resistant to oxidation, acids and alkalis | ★☆☆☆☆ Easy to rust, need to be sprayed or plated for protection | ★★★★☆☆ Good, resistant to atmospheric and water corrosion |

| Ductility | ★★★★☆ Good, can be deep-drawn | ★★★★☆☆ Fair | ★★★★☆ Very good, suitable for finishing |

| Load-bearing capacity | ★★★★☆ Suitable for medium and high strength structures | ★★★★★ High strength, structural steel | ★★★★☆☆ Medium, preferred for non-load-bearing |

| High temperature resistance | Excellent (operating temperature up to 870°C) | Average (<400°C) | Average (<200°C, zinc content) |

| Typical use | Food equipment, medical equipment, outdoor hardware | Building structure parts, mechanical support, welding parts | Valve, plumbing fittings, instrumentation, decorative parts |

Selection and purchase of key parameters

Material Grade

Choose 304 stainless steel for humid environment, 316 stainless steel must be chosen for seaside or chemical plant.

Physical specifications

Thickness: blade thickness 2-5mm, the thicker the higher the load bearing. Pin diameter: 8-12mm, the larger the diameter, the more stable. Bearing type: common bearing with low cost, ball bearing is smoother and longer life.

Installation

Screw fixing: need to pay attention to the hole distance matching, recommended stainless steel screws to prevent rust. Welding type: suitable for permanent installation, but need professional operation.

Certification standard

Priority is given to products that have passed ISO and RoHS certification to ensure environmental protection and safety.

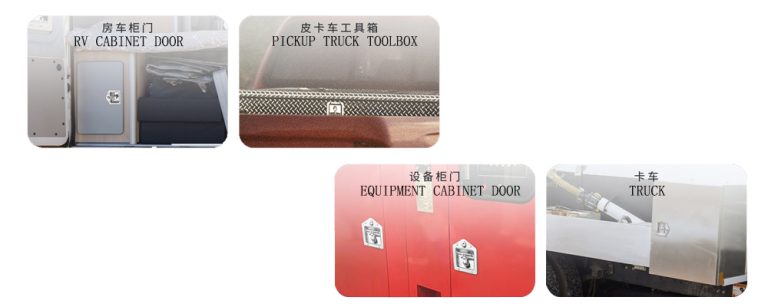

Application Scenarios

| Application Type | Examples |

|---|---|

| Industrial Equipment | Cabinet door, control box, production line protective door |

| Outdoor Scenes | Power distribution box, communication base station door, seaside villa door |

| Special Needs | Bank vault door, hospital sterile room door, subway car door |

Installation Recommendations

Steps list

Measure the thickness and weight of the door, choose the number of hinges (usually 2-4 groups per door). Align the door frame and door, mark the drilling position. Use stainless steel self-tapping screws or welding fixing to ensure perpendicularity.

Precautions

Leave 1-2mm gap to prevent friction. Increase the number of hinges when the door is too heavy to avoid sagging.

Maintenance and care

Cleaning: Wipe with soft cloth, avoid strong acid cleaner.

Lubrication: Apply PTFE spray (Teflon material) every 6 months to prevent dust and non-stick.

Inspection cycle: check the pin wear every 1 year and replace the loose parts in time.

FAQ

Stainless steel butt hinges page rattles after installation?

Check core alignment and apply grease to reduce friction.

How do I prevent butt hinges from rusting?

Regularly clean the surface of water stains, avoid contact with corrosive liquids.

How do I choose the specifications for a butt load bearing hinge?

Select the thickness according to the weight of the door, 3mm for regular doors, 4mm or more for heavy doors.

Conclusion

Heavy-duty stainless steel butt hinges page has the advantages of corrosion resistance, high load-bearing, long life, etc., the selection needs to look at the material, bearings, mounting methods, suitable for industrial, commercial and special scenes