HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In various industrial uses, especially the food and chemical manufacturing sectors, the Industrial Hinge is a vital part. constructed to endure severe conditions and considerable weight, this type of hinge ensures smooth and reliable operation of machinery.We will explore the relevance of Industrial Hinges, their uses, and the important considerations to consider when choosing the optimal hinge options for your particular requirements in this article.

Longevity and resistance to rust are the primary requirements for Industrial Hinges.Industrial Hinges should endure harsh chemical substances, severe temperatures, and physical stress.We will discuss the materials and coatings used in the creation of these hinges, as well as their functionality in various conditions in this section.

Another key element to consider in chooseing industrial equipment fittings is their carrying capacity and load distribution.industrial equipment fittings must be capable of supporting substantial weights and ensuring uniform distribution of the load across the hinge.This section will delve into the structural and engineering features that contribute to the hinge’s sustaining capacities.

Recommend 3 excellent mechanical hinges

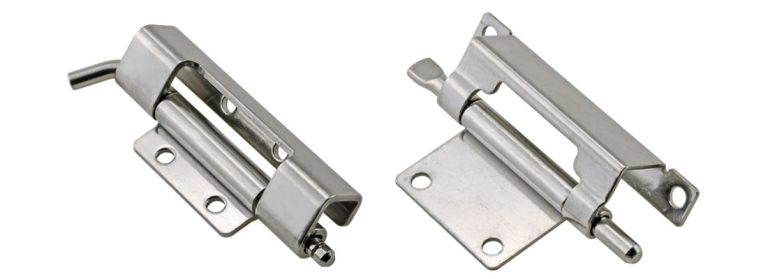

Heavy Duty Industrial Equipment Hinges

Heavy Duty Industrial Equipment Hinges Material: Stainless Steel Surface Treatment: Mirror Finish Size: 80x69mm Thickness: 8mm Main Applications: Industrial Cabinets, Electrical Cabinets, Fire Cabinets, Communication Boxes, etc.

304 Stainless Steel No-Hole Round Welding Hinges

304 stainless steel round welded hinges without holes CL253-10, the surface of the vibration light treatment, the size of 25.4 * 9.7mm, thickness of 1mm, mainly used for instrumentation, industrial equipment, chassis, base cabinets and so on.

304 Stainless Steel Three-Fold Hinges

Thickened 304 Stainless Steel Three-Fold Hinge CL252 With a mirror-polished surface finish and a concealed installation design, this hinge is fixed with M5 through-hole screws. It is primarily used for industrial cabinet doors, equipment cabinet doors, control cabinets, switch cabinets, and more.

Especially in massive industrial uses, industrial equipment fittings should be simple fixing and maintain.This section will discuss the design characteristics that facilitate effortless and convenient fixing, as well as the upkeep needs that ensure the hinge’s durability.The ability to customize industrial equipment fittings to fit unique specifications and ensure suitability with various machinery is essential, lastly.

This section will explore the configuration choices available, such as various hinge dimensions, forms, and substances, as well as the importance of ensuring consistency with current equipment.extreme conditions, including severe temperature variations, detrimental substances, and physical strain, are exposed to dining and processing hardware links.

These hinges are usually produced from high-quality substances such as rust-resistant steel, alu, or tailored alloys to ensure their durability and dependability.Offering excellent anticorrosion properties, these substances can withstand temperatures ranging from -200°C to 600°C.Further enhancing the hinge’s resistance to corrosion and wear, coverings such as Zn-Ni alloy, electronophoretic epoxy, or Teflon are often applied, in addition to material selection.

Preventing the hinge from coming into direct contact with harmful substances, these coverings provide a defensive coating, thereby extending its lifespan.Ensuring the smooth machine performance, the load bearing capacity of dining and processing hardware links is a critical factor.While maintaining a small and light construction, these hinges are designed to cope with substantial burdens, often exceeding 10 kg.

The key to achieving this rests in the design and construction of the hinge.The design of the hinge commonly employs ball or roller bearings to decrease friction and evenly distribute the load across the hinge.in addition to these bearings reduce wear and tear, ensuring the hinge’s endurance.quick and simple installation is integrated into Food and Chemical Machinery Hinges, reducing downtime and work expenses.

Pre-drilled holes and installation hardware provided with the hinges, making it simple to connect them to the machinery.Moreover, the hinge’s design allows for easy disassembly and maintenance, ensuring that any issues can be tackled promptly.A key benefit of Food and Chemical Machinery Hinges rests in customization, allowing them to be tailored to fit specific requirements.

producers offer a large assortment of hinge dimensions, types, and materials, ensuring the hinge can can readily be incorporated into various machines.Compatibility with current equipment is also a priority, as these hinges are designed to fit together effortlessly with different types of equipment.Especially in the food and chemical processing industries, Food and Chemical Machinery Hinges are essential components in various industrial applications.

Their sturdiness, anticorrosion property, loading capacity, simple installation, and tailoring make them a dependable option for guaranteeing seamless and effective machinery functioning.By taking into account the critical elements addressed in this article, one can choose the optimal hinge options for your unique requirements, which will finally lead to enhanced efficiency and lowered stoppage time.

HTAN accepts OEM orders and can customize the size, material, surface treatment, and other specifications according to your requirements.