HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Ideally, industrial connection components must do more than just join a door to a frame; they must also address space and safety concerns—which is exactly where Flat Head Hinges excel. By replacing standard protruding hinges that consume extra space and can injure personnel, Flat Head Hinges solve these common pain points with their distinct “flush” design.

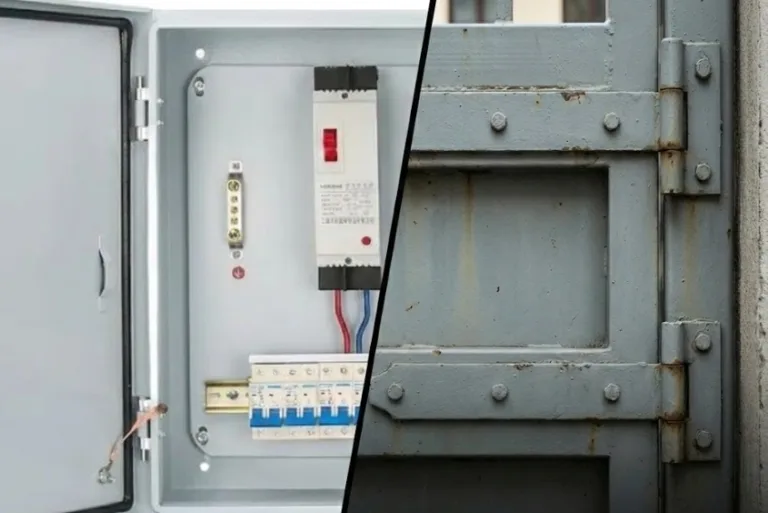

Once installed, they remain basically flush with the door panel surface. This characteristic makes them the ideal choice for server racks, precision equipment enclosures, and heavy-duty industrial doors.

They offer a perfect balance of structural strength, space utilization, and operational safety.

Quick Definition: A Flat Head Hinge is an industrial hinge designed with a non-protruding head. It is typically used with countersunk screw holes. When installed, the hinge surface sits flush with the door panel. This design is aesthetically pleasing and prevents accidental impact damage.

Deep Dive into Flat Head Hinges

Core Definition and Features

The core feature of a flat head hinge is its “flatness.” Unlike traditional butt hinges, it has no obvious protrusions on its visible surface.

To achieve this, the design typically includes two key elements:

- Flat Pin Head: The ends of the hinge pin lack decorative ball or crown tips.

- Countersunk Holes: The screw holes on the leaf are countersunk. This allows flat-head screws to be buried completely within the leaf.

Flat Head Hinges vs. Standard Hinges: 3 Key Differences

To help procurement managers and engineers distinguish between them quickly, here is a summary of the differences:

Appearance and Space Footprint

- Standard Hinges: The knuckle and screw heads protrude from the surface. In tightly packed cabinet arrays, this can cause interference.

- Flat Head Hinges: The surface is smooth. They achieve a “zero-profile” installation. This is perfect for tight spaces or equipment with strict aesthetic requirements.

Safety Considerations

- Standard Hinges: Protruding edges can scratch operators or snag clothing.

- Flat Head Hinges: The protrusion-free design significantly reduces safety hazards. This is a critical safety feature in corridors or high-traffic industrial zones.

Installation Methods

- Standard Hinges: Mostly surface-mounted.

- Flat Head Hinges: Flexible and diverse. They support surface mounting as well as Mortise (Embedded) mounting. For heavy-duty applications, Welded versions are available for increased structural strength.

Structural Composition and Engineering Principles

Key Component Breakdown

While the structure looks simple, industrial-grade flat head hinges are reinforced in the details:

- Hinge Leaf: The core load-bearer. Leaf thickness usually ranges from 2mm to 5mm. This determines the hinge’s shear resistance.

- Hardened Pin: Industrial-grade pins often undergo heat treatment. Hardness can reach HRC 50–55. This ensures the pin will not bend under high loads.

- Friction-Reducing Bushings: High-end models include oil-impregnated bearings or brass bushings between the shaft and leaf. This significantly reduces the coefficient of friction and prevents metal dusting.

Mechanical Working Principles

Flat head hinges withstand forces in two directions via the pin:

Static Tension: The dead weight of the door panel when closed.

Dynamic Impact: The torque generated during the opening and closing moments.

Reliability Standards: High-quality flat head hinges must pass cycle life testing. For example, heavy-duty hinges complying with the EN 1935 standard must pass at least 200,000 opening/closing cycles without functional failure.

Material and Type Classification Guide

Classification by Material (Corrosion Resistance Analysis)

- 304 Stainless Steel: The industrial standard configuration. Offers good rust resistance. Suitable for most indoor/outdoor environments and food processing equipment.

- 316 Stainless Steel: The first choice for harsh environments. Contains molybdenum for strong resistance to chloride corrosion. Strongly recommended for seaside locations, chemical plants, or pharmaceutical cleanrooms.

- Carbon Steel (Galvanized/Powder Coated): High strength, low cost. Suitable for heavy machinery doors in dry environments. You must ensure the surface anti-rust coating remains intact.

- Aluminum Alloy: A lightweight choice. Suitable for flight cases or mobile instrument equipment. Not suitable for high-frequency, heavy-load scenarios.

Classification by Function

- Fixed Type: The pin is non-removable. This structure is the most stable and offers good security/anti-theft properties.

- Lift-off (Detachable) Type: The door panel can be quickly lifted off. Perfect for scenarios requiring frequent maintenance of internal equipment.

- Damping/Soft-Close: Prevents the door panel from slamming shut. Protects precision instruments.

- Large Angle Opening: Designed for special cabinets. Allows the door panel to open up to 270°, folding completely against the side of the cabinet.

Analysis of 5 Major Industrial Application Scenarios

Industrial Cabinets and Server Racks

- Pain Point: Cabinets are usually deployed in rows with minimal gaps.

- Solution: The “zero protrusion” feature of flat head hinges allows cabinets to sit tightly side-by-side. When paired with sealing strips, achieving an IP65 protection rating is easy.

Heavy Machinery Access Doors

- Pain Point: Heavy door panels accompanied by equipment vibration.

- Solution: Select extra-thick carbon steel or stainless steel flat head hinges. We recommend using nylon lock nuts to prevent vibration from loosening the screws.

Cleanrooms and Medical Equipment

- Pain Point: Requirements for no sanitary dead zones and resistance to chemical cleaning.

- Solution: You must select 316L polished stainless steel flat head hinges. The smooth surface is easy to wipe down and does not accumulate bacteria.

Outdoor Power and Telecom Cabinets

- Pain Point: Salt spray corrosion, wind, sun, and rain.

- Solution: We recommend using electropolished stainless steel hinges. During selection, require the supplier to provide an NSS Salt Spray Test Report (recommended 480 hours or more).

Selection, Installation, and Troubleshooting Guide

Key Selection Parameter Checklist

Before placing an order, be sure to verify the following parameters:

Load Capacity: Always reserve a safety factor. Reserve 1.5x for static loads and 3x for dynamic loads.

Opening Angle: Confirm if you need 90°, 180°, or 270°.

Environmental Grade: 304/316 Stainless Steel is mandatory for outdoor use.

Installation Space: Confirm that the door frame has enough width to accommodate the hinge leaf.

Common Selection Mistakes to Avoid

- Underestimating Door Weight. Estimating by feel alone leads to hinge deformation and sagging.

- Wrong Material for Outdoors. Using 201 or 304 stainless steel at the seaside leads to rapid rusting. Seaside environments must use 316 grade.

- Mismatched Screw Holes. Failing to check the hole spacing drawing before purchase leads to installation failure.

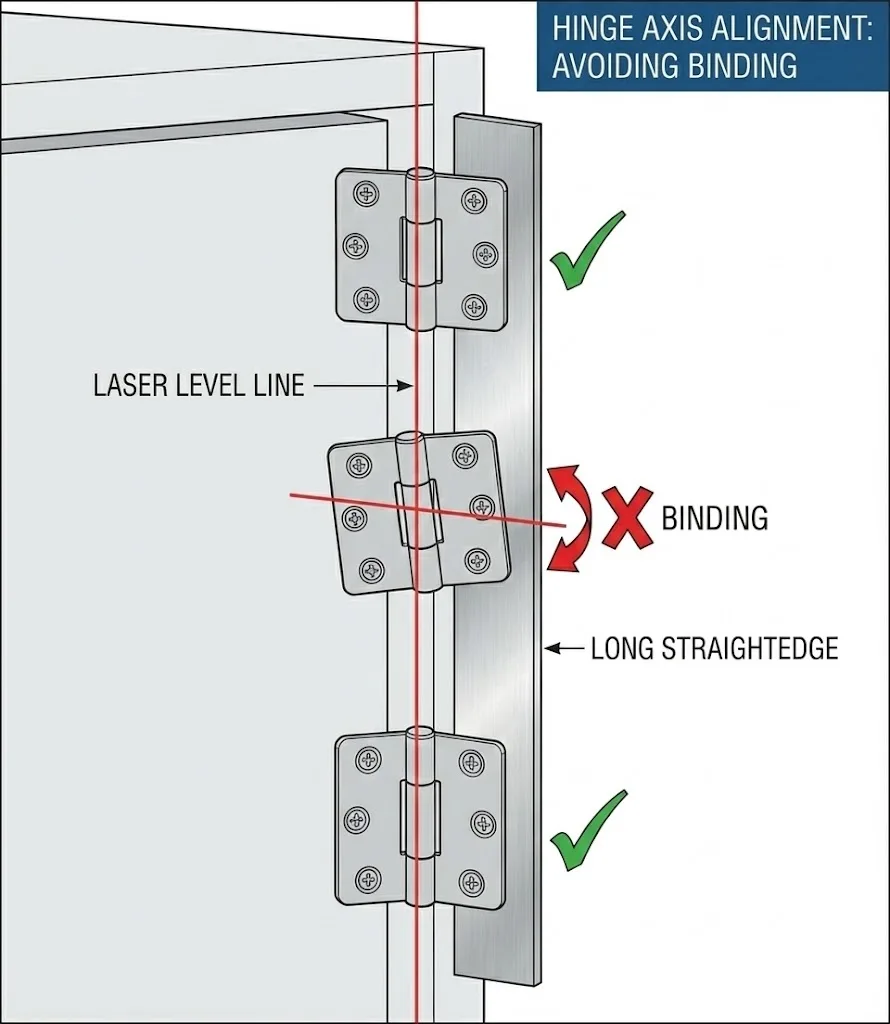

Installation and Maintenance Tips

- Installation: Use a torque wrench whenever possible. When installing multiple hinges, ensure the axes are on the exact same vertical line. Failure to do so will cause binding and squeaking.

- Maintenance: For outdoor equipment, inspect every 6-12 months.

- Lubrication: Use white lithium grease or PTFE lubricant. Warning: Avoid long-term use of WD-40, as it evaporates and can strip away the original grease.

FAQ

Here are answers to specific procurement intents and technical challenges:

Q1: How do I measure and retrofit old flat head hinges?

A: When retrofitting, focus on three dimensions: 1. The total length and width of the hinge (open dimensions); 2. The thickness of the leaf; 3. The hole spacing (center-to-center distance of adjacent holes). If you cannot find a product with identical hole spacing, we recommend buying Undrilled flat head hinges and drilling the holes yourself to match the site conditions.

Q2: Can I use flat head hinges on aluminum profiles (T-slot)?

A: Yes, but pay attention to the mounting method. Aluminum profiles typically have T-slots. You will need to use T-nuts or slider nuts to secure the hinge. If the countersunk holes of the flat head hinge do not match the T-nuts (which usually take socket head or pan head screws), you may need to use countersunk screws with special countersunk washers, or tap threads directly into the aluminum (not recommended for heavy doors).

Q3: Why is my stainless steel flat head hinge rusting outdoors?

A: This is usually “tea staining” or iron contamination. There are two likely causes: 1. Incorrect material selection (using 304 instead of 316 at the seaside); 2. Using ordinary carbon steel screwdrivers during installation, which left iron residue on the stainless steel surface. We recommend cleaning the surface with passivation fluid and ensuring installation tools are clean.

Q4: How should I position hinges on a heavy industrial door?

A: For heavy doors, do not distribute hinges evenly. We recommend the “High-Frequency Top” method: Install two hinges at the top of the door (with smaller spacing between them) and one hinge at the bottom. Since the top hinge withstands the maximum tensile force (overturning moment), adding density to the top significantly prevents the door panel from sagging.

Q5: Are flat head hinges fire-rated?

A: All-metal (e.g., 304/316 stainless steel or carbon steel) flat head hinges have inherent high-temperature resistance. However, to be used on a designated Fire Door, the hinge must have specific fire certification (such as UL Certification or EN 1634 standard testing). When purchasing, be sure to request the fire certificate from the supplier; do not rely solely on the material.

Q6: Which is stronger: welded installation or flat head screw installation?

A: Welded installation generally offers higher strength and eliminates the issue of screws loosening. It is perfect for heavy equipment with high vibration or high security requirements. The downside is that it is non-removable, making maintenance extremely difficult, and the welding heat may damage internal nylon bushings. If there is no specific high-strength anti-theft requirement, screw installation combined with thread-locking fluid (Loctite) is usually the more balanced choice.