HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Why do some plastic handles remain robust after a decade of use, while others snap during their first field deployment? The answer typically lies not in the mold design, but in the specific resin pellets fed into the injection molding machine hopper.

In analyzing post-sales quality complaints, we’ve found that over 70% of handle fractures stem from a misjudgment of material properties. Engineers often overestimate the dynamic load-bearing capacity of ABS or overlook the dimensional changes of PA66 (Reinforced Nylon) after moisture absorption.

To address this industry pain point, we have compiled first-hand data based on destructive laboratory testing. This article provides an in-depth analysis of the real-world performance of PA66 and ABS in industrial environments. From a materials science perspective, we reveal how correct selection can maximize product durability and user experience while controlling costs.

In-Depth Analysis of Core Materials—The Physical Logic of Price vs. Performance

In a Bill of Materials (BOM), the unit price of a PA66 handle is typically higher than that of ABS. This premium doesn’t come from branding, but from the physical modification costs of the polymer. We need to look beyond the price tag to see the differences in micro-structure.

PA66 + 30% Glass Fiber Reinforced (PA66 GF30): The “Metal Replacement” for Heavy Equipment

When your equipment weighs over 20kg, or needs to operate in high-temperature or oily environments, PA66+30%GF is the only viable plastic solution.

- Composition Definition & Modification PrincipleIn an industrial technical datasheet, seeing “PA66+30%GF” means that 30% glass fiber has been mixed into the Polyamide 66 (PA66) base. This physical modification drastically alters the material’s properties.

- Qualitative Leap in Mechanical StrengthAccording to ASTM D638 and ISO 527 standard testing, adding 30% glass fiber can double the tensile strength and significantly increase rigidity. This gives PA66 handles the capability to replace metal handles in certain heavy-duty equipment applications.

- Chemical and Heat ResistancePA66 offers extremely high wear and oil resistance, making it highly suitable for machine shops or around generator sets.

- Visual CharacteristicsDue to the presence of glass fibers, PA66 handle surfaces typically present a matte texture and may show slight fiber patterns. This is a visual characteristic of high-performance engineering plastic, not a defect.

ABS Plastic: The Choice for Precision Instruments and Light-Duty Equipment

If your application demands superior aesthetics and involves lighter loads, ABS is the better option.

- Composition CharacteristicsABS (Acrylonitrile Butadiene Styrene) is an engineering plastic with well-rounded performance.

- Surface Finishing AdvantagesThe greatest advantage of ABS lies in its high surface gloss and ease of electroplating or painting. For medical instrument cases or electronic test equipment, ABS handles can provide a visual texture similar to ceramic or metal.

- Dimensional StabilityABS has a low cooling shrinkage rate, making it less prone to warping and suitable for housing components requiring high-precision fits.

- LimitationsCompared to nylon, the mechanical strength of ABS is mid-range, and it is not recommended for high-load scenarios. Additionally, its solvent resistance is poorer; contact with certain industrial cleaners may cause stress cracking.

Why is Standard PP (Polypropylene) Not Recommended for Industrial Scenarios?

In projects pursuing extreme low cost, PP (Polypropylene) is often considered as an alternative. However, as consultants, we must issue a warning.

- Low-Temperature Brittleness RiskAlthough PP raw material costs are lower6, making it suitable for lightweight packaging, It becomes significantly brittle in low-temperature environments due to its Glass Transition.

- Poor Creep ResistancePP has poor creep resistance and is prone to permanent deformation under long-term stress.

- Engineering AdviceUnless your application is for ultra-lightweight disposable packaging (under 20kg), choosing PP to reduce raw material costs by approximately 20-30% carries a high risk of handle breakage during transport.

Load Testing and Failure Mode Analysis—Data Doesn’t Lie

“Rated Load” is static data, while the real world is full of dynamic impacts. Understanding how different materials perform at their limits helps you avoid catastrophic field accidents.

Static Tensile Test Data Comparison

In our laboratory, we simulated vertical lifting actions and recorded the maximum force (in Newtons) before fracture for handles of different materials.

- Industrial-Grade PA66 (GF30) HandleA high-quality reinforced nylon fixed handle typically achieves a vertical pull force between 500N and 1000N+8888. For most server chassis or equipment access doors, this data provides a very high safety redundancy.

- Standard ABS HandleStandard ABS handles typically have a rated load between 200N and 400N, suitable for light instruments or toolboxes.

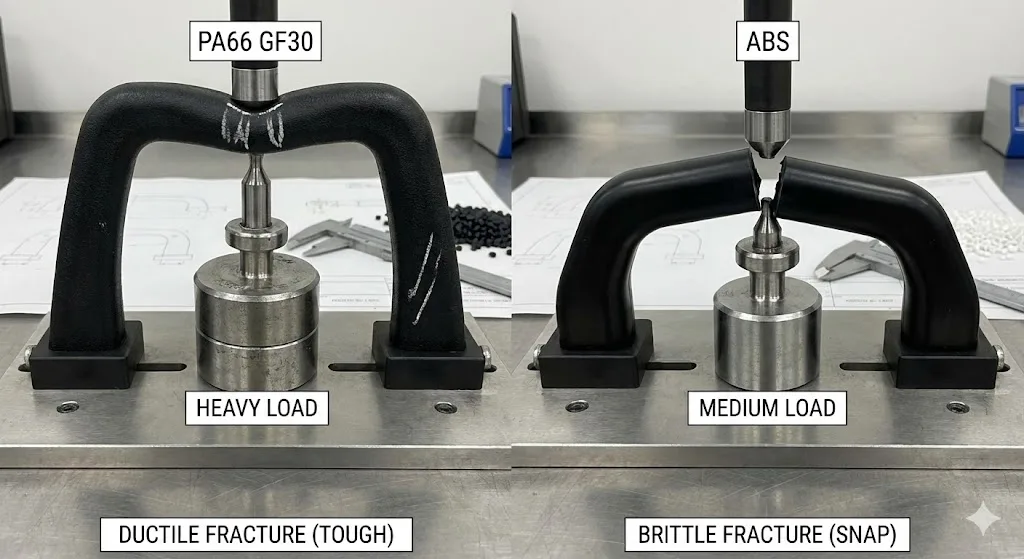

Difference in Failure Modes: Toughness vs. Brittleness

More important than the maximum load is how it breaks.

- PA66 Failure Behavior: Ductile FractureApproaching its stress limit, reinforced nylon typically exhibits “stress whitening,” followed by significant tensile deformation, before finally tearing. This toughness gives the operator reaction time, avoiding the sudden drop of heavy objects.

- ABS Failure Behavior: Brittle FractureOnce ABS exceeds its yield point, it often snaps instantaneously with a clean break and no obvious warning. During heavy lifting, this brittle fracture poses a high risk of personnel injury or equipment damage.

Performance Degradation Under Environmental Stress

Laboratory data is usually measured at room temperature (23°C). In outdoor environments, the situation changes.

- Low-Temperature Impact RiskIn low-temperature environments of -20°C to -30°C, standard plastics become brittle.

- Selection AdviceIf your equipment is destined for cold regions or outdoor operation, you must use high-quality Engineering Nylon (Polyamide). Experience shows that reinforced nylon handles retain sufficient impact toughness even in -30°C environments. Using standard ABS or inferior recycled materials increases fracture risk exponentially.

Hidden Details Determining Lifespan—Inserts and Injection Molding Process

Two black U-handles that look identical may differ in price by double. This difference is often hidden in internal structures invisible to the naked eye.

Metal Insert Material: Brass vs. Zinc-Plated Iron

Most industrial handles are fixed via embedded metal nuts (inserts). This is a high-risk area for corrosion failure.

- The Low-Cost TrapTo win orders through price wars, inferior suppliers often use Zinc-Plated Iron instead of Brass for inserts.

- Corrosion ConsequencesIn humid or outdoor environments, iron inserts rust rapidly. The expansion of rust can crack the plastic matrix or cause the handle to detach directly from the mounting screws.

- Procurement StandardYou must explicitly specify in your technical drawing or procurement contract: Insert material must be H59 Brass or 304 Stainless Steel. You can verify this with a simple magnetic test or salt spray test.

Virgin Material vs. Recycled Material (Regrind)

An open secret in the injection molding industry is the use of recycled material (regrind).

- Destruction of Micro-StructureTo cut costs, some factories mix a high percentage of recycled material into the raw resin. Recycled material has undergone multiple heat and shear cycles, breaking its molecular chains.

- Performance ImpactMixing in recycled material causes the product to become brittle and drastically reduces impact strength.

- Risk AvoidanceYour injection molding contract must include a clause for “100% Virgin Material”. For critical load-bearing components, there is no room for compromise.

Selection Decision Matrix

To simplify your decision-making process, I have compiled the following selection guide based on different application scenarios. Please match your specific operating conditions.

| Application Scenario | Recommended Material Solution | Key Engineering Rationale | Relevant Technical Standard Reference |

| Outdoor Telecom Cabinet | UV-Stabilized PA66 | Requires resistance to long-term UV exposure to prevent chalking and cracking | UL 746C (Polymeric Materials – Use in Electrical Equipment Evaluations) |

| High-Voltage Electrical Cabinet | Flame Retardant PA66 (V0 Grade) | Requires electrical insulation and self-extinguishing properties | UL 94 (Standard for Safety of Flammability of Plastic Materials) |

| Medical/Lab Instruments | ABS / Plated ABS | Requires high gloss, easy cleaning, and aesthetics | – |

| Heavy Machinery/Military Case | PA66 + 30% GF | Requires extreme mechanical strength, heat, and oil resistance | ASTM D638 (Tensile Properties), ASTM D256 (Impact Strength) |

| General Indoor Equipment | Standard PA6 | Balance of strength and cost | – |

Conclusion

Selecting industrial plastic handles is far from simply “ordering from a catalog picture.”

If you pursue extreme strength, durability, and heat/oil resistance, especially when replacing metal handles on heavy equipment, PA66 + 30% Glass Fiber Reinforced Material is the only professional choice.

If you focus on aesthetic design, surface finishing, and precision feel under light loads, ABS is the more suitable material.

As a procurement manager or engineer, I suggest that in your next Request for Quotation (RFQ), instead of just asking “what is the unit price,” require the supplier to provide the following three documents:

Certificate of Analysis (COA): Confirming the use of virgin material.

Tensile Test Report: Confirming static fracture force values.

Insert Material Specification: Confirming Brass or Stainless Steel.

These data-driven requirements will help you filter out 90% of low-end traders and build a robust supply chain for your equipment.

FAQ

Q: Will Nylon (PA66) handles become soft after absorbing water?

A: Yes, Nylon is hygroscopic. After absorbing moisture, Nylon’s toughness increases, but its rigidity and tensile strength decrease slightly. Moisture absorption also leads to minor dimensional changes. You must allow for appropriate tolerances when designing high-precision mounting holes.

Q: Can plastic handles be used on food machinery?

A: This depends on specific certifications. Ordinary industrial black nylon is not recommended for direct food contact. Its surface micropores can harbor contaminants, and you must verify if colorants and additives meet FDA or NSF standards. For the food industry, we recommend prioritizing electropolished 316 Stainless Steel handles.

Q: How can I quickly distinguish between PA66 and ABS handles?

A: You can make a preliminary judgment via sensory inspection: PA66 reinforced with glass fiber usually has a fine matte texture and produces a dull sound when tapped; ABS has a very smooth surface and produces a crisp sound when tapped. In a lab setting, a burn test can be used: ABS burns with black smoke and a sweet smell, while Nylon burns with a smell similar to burnt wool or fingernails.

Q: Why do some nylon handles break after just a few months?

A: Aside from overloading, the most common reason is the supplier using a high percentage of recycled material (Regrind) , or using ordinary nylon without UV stabilizers in outdoor environments, causing the material to rapidly age and become brittle under UV radiation. Always specify UV-resistant materials.