HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Crucial for harsh environments, a high-quality outdoor stainless steel hinge relies on invisible chemistry to fight rust. From the protective ‘passivation film’ to the choice between 304 and 316, here is everything engineers and buyers need to know to prevent corrosion and extend hardware service life

Conclusion: 3 Key Reasons for Corrosion Resistance

If you are looking for a quick answer, here are the three core factors.

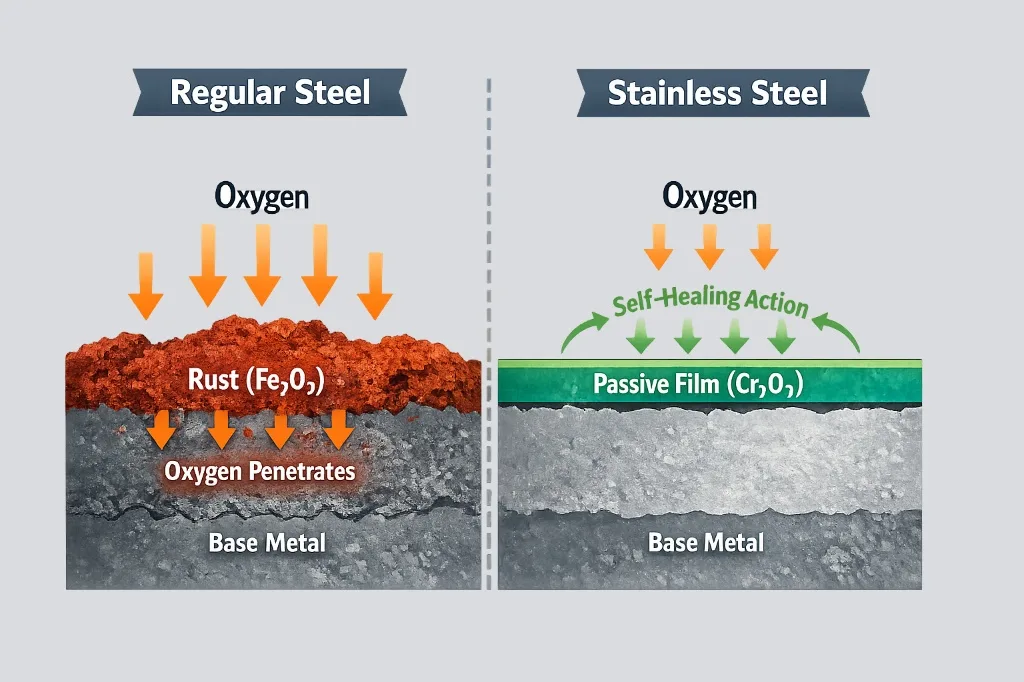

The Surface “Passivation Film” is the First Line of Defense

- The chromium element in the stainless steel alloy reacts with oxygen.

- This reaction rapidly forms a dense chromium oxide passivation film on the hinge surface.

- This transparent film is only a few nanometers thick.

- However, it firmly adheres to the metal surface.

- It effectively isolates moisture and oxygen, preventing rust.

- Self-Healing: Even if the surface suffers minor scratches, this film can automatically repair itself as long as oxygen is present.

Alloying Elements (Chromium, Nickel, Molybdenum) Determine the Limit

- The corrosion resistance depends on the specific alloy formula.

- Chromium (Cr): High chromium content (usually ≥10.5% Cr) is the foundation for forming the passivation film.

- Nickel (Ni): Stabilizes the crystal phase and prevents brittleness.

- Molybdenum (Mo): Found in 316 stainless steel (approx. 2%). It significantly improves resistance to pitting corrosion.

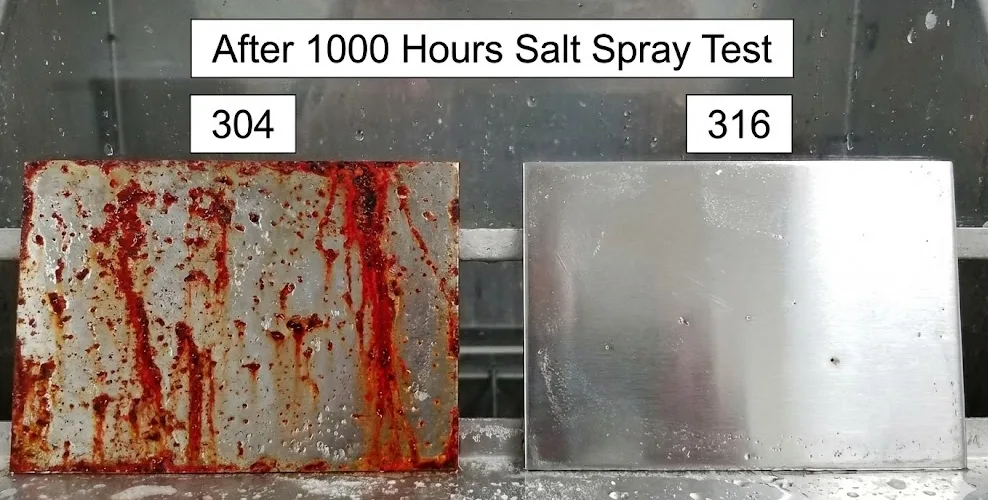

- Comparison: 304 stainless steel (approx. 18% Cr, 8% Ni) has excellent resistance. 316 adds ~2–3% molybdenum (Mo) to the 304 base, earning the title “Marine Grade” for its superior performance in salt spray environments.

Correct Grade + Correct Installation = Extended Lifespan

- Selecting the steel grade that matches the environment is critical.

- General Outdoors: 304 stainless steel is sufficient.

- Coastal/High Humidity: 316 or higher grades are recommended.

- Installation: Use correct accessories (e.g., stainless steel screws of the same material) and avoid water-trapping gaps.

- Result: With good design and maintenance, outdoor service life is significantly extended.

Summary: The outdoor durability of stainless steel hinges is due to the self-forming passivation film, the anti-rust capabilities of Cr-Ni-Mo alloys, and correct material selection combined with maintenance. These three factors work synergistically to prevent rust in harsh environments like humidity and salt spray.

Why Do Outdoor Hinges Rust Easily? Understanding the Sources

Before discussing prevention, we must understand the root causes of outdoor metal corrosion. Even small components like hinges are subject to these factors.

Water and Oxygen: Basic Conditions for Reaction

Water (humidity, rain, condensation) and oxygen are the two fundamental prerequisites for corrosion.

- Ordinary Steel: Reacts to form loose iron oxide (rust). This rust absorbs moisture and spreads, causing continuous corrosion.

- Stainless Steel: It needs oxygen to maintain its passivation film. However, long-term exposure to water without airflow (oxygen deprivation) or extreme pH levels can damage this film.

Salt Spray / Sea Breeze: The Coastal Accelerator

In coastal environments, the air is filled with salt (chloride ions).

- Sea breezes and marine aerosols deposit salt spray onto equipment.

- Chloride Ions: These are accelerators for stainless steel corrosion. They can penetrate and destroy the passivation film, triggering pitting corrosion.

- Impact: Corrosion rates at the seaside can be several times higher than inland. A hinge that lasts years inland might show rust spots in months at the coast.

- Standards: ISO 9223 classifies coastal atmospheres as C5 (Very High Corrosivity), requiring materials like 316 stainless steel.

Acid Rain, Pollution, and Chemical Cleaners

- Acid Rain: Modern pollution lowers rain pH (sometimes to around 4), accelerating oxidation.

- Industrial Pollutants: Sulfur dioxide and nitrogen oxides dissolve in water to form acids, depositing on hinges.

- Chemical Cleaners: Improper use of chlorine-containing cleaners (e.g., bleach) is a major killer. Chlorides destroy the passivation film rapidly.

- Residue: Chemicals like strong acids or alkalis left on the hinge will trigger corrosion.

Localized Corrosion Mechanisms (The Cause of “Rust Spots”)

Rust on stainless steel often appears as spots rather than uniform rusting.

- Pitting: Small holes caused by chloride ions penetrating the film. Common in 304 steel in salty environments.

- Crevice Corrosion: Occurs in tight gaps (e.g., under screws or inside bearings) where water enters but oxygen cannot. The environment becomes acidic, destroying the film.

- Galvanic Corrosion: When stainless steel touches a different metal (like carbon steel screws) in the presence of water. The less noble metal (carbon steel) corrodes, contaminating the stainless steel with rust stains.

What is the “Corrosion Resistance Principle” of Stainless Steel Hinges?

The Passivation Film: A Self-Healing Shield

The core secret is the passivation film composed mainly of Chromium Oxide ($Cr_2O_3$).

- When exposed to oxygen, the chromium in the steel reacts immediately.

- It forms a dense, invisible oxide layer.

- Self-Repair: If the film is damaged by a scratch, the exposed chromium reacts with oxygen again to “heal” the breach.

- Limitations: In oxygen-deprived gaps or high-chloride environments, this film may break down faster than it can repair.

Why Can’t Ordinary Steel/Iron Do This?

- Carbon Steel: Forms iron oxide (rust). Rust is porous and flaky. It does not stop water/oxygen penetration; it actually encourages it.

- Galvanizing: Zinc coatings act as a sacrificial barrier. However, once the zinc layer is consumed or scratched, the underlying steel rusts immediately.

- Stainless Steel: Relies on the material’s inherent chemistry, not a temporary coating. It does not “run out” of protection as long as the alloy structure is intact.

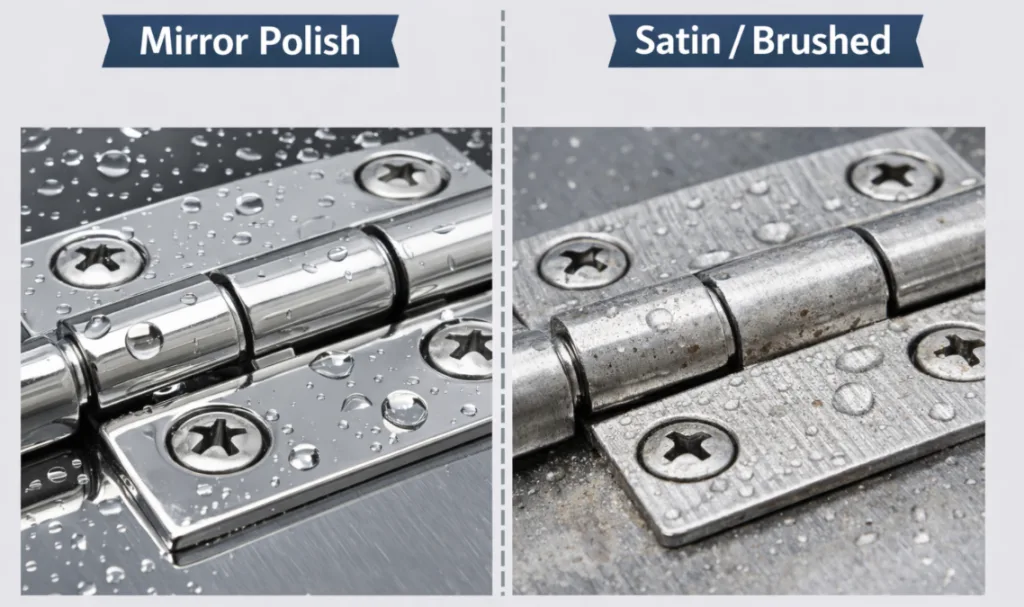

Impact of Surface Finishes

The physical surface finish affects corrosion resistance significantly.

- Mirror Polish: Highly smooth. Best for outdoors. Dirt and salt cannot adhere easily.

- Satin/Brushed: Has microscopic grooves (hairlines). Can trap dust and salt, leading to “tea staining” rust. Requires more frequent cleaning.

- Pickling and Passivation: A chemical process that removes surface iron and contaminants. Enhances the chromium layer. Crucial for high-grade hardware.

- Electropolishing: Dissolves surface peaks. Creates the purest, most corrosion-resistant surface. Ideal for marine use.

304 vs. 316 vs. 201: How to Choose for Outdoors?

Here is a breakdown of the three most common materials.

304: The General Purpose Choice

- Composition: ~18% Chromium, ~8% Nickel.

- Performance: Excellent for most outdoor environments (inland cities, rural areas).

- Pros: Good balance of cost and performance.

- Cons: Will develop rust spots or “tea staining” in coastal or high-salt environments.

316: The Coastal/Marine Choice

- Composition: ~16% Chromium, ~10% Nickel, 2-3% Molybdenum.

- Performance: The Molybdenum drastically improves resistance to chlorides (salt).

- Application: Coastal villas, boats, swimming pools, high-pollution areas.

- Pros: Long-term reliability in harsh conditions.

- Cons: Higher cost (approx. 15-25% more than 304).

201: The Low-Cost/High-Risk Choice

- Composition: Low Nickel (3.5-5.5%), High Manganese.

- Performance: Significantly lower corrosion resistance.

- Risk: Likely to rust within months in humid or outdoor environments.

- Verdict: Not recommended for outdoor use unless budget is the only concern and the climate is dry.

Comparison Table

| Material Grade | Key Alloy Composition | Corrosion Resistance | Typical Outdoor Application | Relative Cost |

| 304 (A2) | Cr ≈ 18%, Ni ≈ 8% | Excellent (General) | Garden gates, toolboxes, inland structures | $$ (Base) |

| 316 (A4) | Cr ≈ 16%, Ni ≈ 10%, Mo ≈ 2% | Superior (Marine) | Coastal homes, pools, chemical plants | $$$ (+20%) |

| 201 | Cr ≈ 16%, Ni < 5%, High Mn | Poor/Fair | Indoor furniture, temporary dry use | $ (-20%) |

Myths: Can Stainless Steel Hinges “Rust”?

Yes, they can appear to rust, but often it is a misunderstanding.

“Float Rust” (Contamination)

- Often, the rust you see is not the hinge itself.

- It is iron dust from tools, steel wool, or the environment that has settled on the surface and rusted.

- Fix: Wipe it off. If it cleans off to reveal shiny metal, it was just surface contamination.

Galvanic Corrosion (Installation Error)

- Using Carbon Steel screws with Stainless Steel hinges.

- The screw rusts rapidly due to the electrical potential difference.

- The rust runs onto the hinge, making the hinge look defective.

- Fix: Always use stainless steel screws.

Cleaning Errors

- Using bleach or cleaners containing chlorides.

- This destroys the passivation layer rapidly.

- Fix: Use mild soap and water only.

Installation & Maintenance: Double the Lifespan

Select the Right Accessories

- Match Materials: 304 hinges with 304 screws. 316 hinges with 316 screws.

- Isolation: If mounting to an aluminum or carbon steel frame, use nylon washers or a sealant to break the electrical contact (prevent galvanic corrosion).

Design for Drainage

- Orientation: Install hinges so drainage holes face down.

- Avoid Standing Water: Ensure no gaps trap water permanently.

- Sealing: Use waterproof sealant on fixed gaps.

Maintenance Cycle

- Clean: Wash with fresh water to remove salt deposits (Monthly for coastal, Quarterly for inland).

- Inspect: Check for loose screws or early rust spots.

- Lubricate: Apply a drop of stainless-safe lubricant (e.g., PTFE based) to the pivot point every 6-12 months.

How to Verify You Bought “Real” Stainless Steel?

The Magnet Test

- Concept: Austenitic steel (304/316) is generally non-magnetic.

- Limitation: Cold working (bending/stamping) can make 304/316 slightly magnetic.

- Verdict: Strong magnetism = Fake/400 series. Weak magnetism = Could still be real 304/316. Do not rely on this solely.

Markings and Documents

- Stamps: Look for “SS304”, “AISI 316”, “A2”, or “A4” stamped on the part.

- Reports: Request a Material Certificate (Mill Test Report) showing chemical composition. Check if Molybdenum is present for 316 claims.

Supplier Communication Template

When ordering, be specific:

Grade: “Must be AISI 316 (EN 1.4401).”

Standard: “Must pass ASTM B117 Salt Spray Test for X hours.”

Accessories: “Screws must match hinge grade.”

Verification: “We may perform XRF spectral analysis on receipt.”

FAQ

Q: Will stainless steel hinges definitely never rust outdoors?

A: No. They are “stain-less,” not “stain-impossible.” In extreme salt or acid environments, or if neglected, they can corrode. However, quality hinges usually only show superficial discoloration rather than structural rot.

Q: Is the difference between 304 and 316 really that big?

A: In mild climates, no. In coastal/salt environments, yes. 316 can last years without pitting, while 304 may show damage within months due to salt exposure.

Q: How do I remove rust spots if they appear?

A: Use a dedicated stainless steel cleaner or a mild abrasive pad (non-metallic, like Scotch-Brite). Scrub with the grain. Rinse thoroughly. Passivation paste can be used for deep cleaning.

Summary

To achieve the best corrosion performance for outdoor hinges:

- Select the Grade: Upgrade to 316 for coastal/harsh areas. Use 304 for general outdoors.

- Install Correctly: Use matching stainless screws and ensure drainage.

- Maintain: Clean regularly with fresh water and mild soap.

By following this guide, you ensure your hardware remains functional and aesthetically pleasing for years to come.

-768x768.png)