HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Why the Material Selection for Paddle Latches is Crucial

This article is a technical procurement guide aimed at deconstructing three mainstream paddle latches materials: stainless steel, zinc alloy, and engineering plastic (For industrial context on why paddle latch selection is critical, see Industrial Enclosures Guide). The analysis is strictly structured around four dimensions: security, durability, design flexibility, and economy.

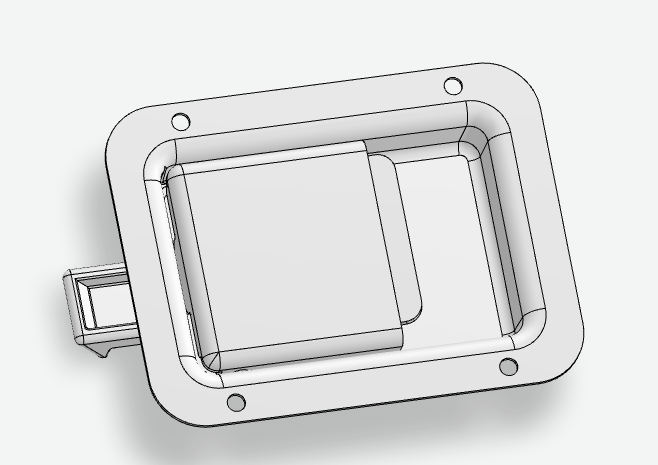

Basic Composition of Paddle Latches and Material Applications

Paddle latches consist of several key components:

- Handle (Handle/Lever): The part directly contacted by the user, with high requirements for appearance and wear resistance.

- Panel (Escutcheon / Rose): The decorative plate covering the door hole.

- Lock Body (Lock Body / Mortise Case): The core mechanical structure inside the door, determining security and durability.

- Cylinder (Cylinder): The part where the key is inserted, the core of security.

The material application mapping is as follows: Stainless steel is commonly used for handles, panels, and lock body shells, especially in high-security or high-corrosion environments. Zinc alloy is the mainstream choice for manufacturing handles and panels. Plastic is used for handles in low-security demands or silent bushings inside the lock body.

Material is the foundation determining the performance of locks, directly affecting whether the lock can meet the security level and durability requirements of its application environment.

Defining the Four Key Criteria for Evaluating Lock Materials

Security and Strength

The material’s ability to resist physical damage (impact, tension). This is usually measured based on the grades (Grade 1, 2, 3) of the ANSI/BHMA A156.x series standards or the security levels (A level, B level) of GB 21556-2008. Different A156 sub-standards (such as door locks, deadbolts, hinges) have varying test contents, with Grade 1 typically representing the highest mechanical strength and durability grade.

Durability and Weather Resistance

The ability to resist long-term wear and environmental factors (corrosion, UV). Corrosion performance is usually compared through the hours of neutral salt spray test (NSST) in ISO 9227 for acceleration. ISO 12944-6 provides coating system references for different corrosion environment grades (C1–C5), but salt spray hours are not directly equivalent to actual service years, serving only as relative indicators for reference.

Appearance and Design Flexibility

The material’s processing and forming ability (ability to manufacture complex shapes) and diversity of surface treatments.

Cost and Economy

Divided into: 1) Raw material procurement cost; 2) Processing and manufacturing cost. Stainless steel has “double high” raw material and processing costs. Zinc alloy’s die-casting process greatly reduces the manufacturing cost of complex shapes.

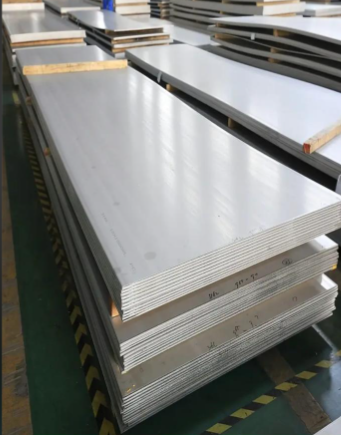

Stainless Steel

What is Stainless Steel?

Stainless steel is an iron-based alloy containing at least 10.5% chromium (Cr). Chromium reacts with oxygen on the material surface to form a dense passivation film (chromium oxide), which can self-repair and isolate iron from environmental contact, thereby providing excellent corrosion resistance.

Common Stainless Steel Types in Locks

304 Stainless Steel

- Standard Definition: ASTM A240 Type 304; Corresponding to 06Cr19Ni10 in China’s GB/T 3280-2015.

- Composition: Approximately 18% chromium (Cr) and 8–10.5% nickel (Ni).

- Characteristics: The most widely used “general-purpose” stainless steel, with excellent corrosion resistance and mechanical properties.

- Applicable: Indoor and most non-coastal outdoor environments.

316 Stainless Steel

- Standard Definition: ASTM A240 Type 316.

- Composition: Adds 2–3% molybdenum (Mo) on the basis of 304.

- Characteristics: “Marine-grade” stainless steel, with extremely high resistance to pitting corrosion caused by chlorides (salt spray, sea breeze).

- Applicable: Coastal, high-salinity, or chemical environments.

201 Stainless Steel

- Standard Definition: GB/T 4237-2015.

- Composition: Low-nickel, high-manganese (Mn) type, using manganese to replace part of nickel to reduce costs.

- Characteristics: Cost lower than 304, but poorer corrosion resistance and weldability, with increased magnetism after cold working.

- Applicable: Limited to dry indoor environments, not recommended for humid or coastal areas.

Core Advantages of Stainless Steel Paddle Latches

- High Corrosion Resistance: No additional coating needed, 316 grade can resist high salt spray environments.

- High Strength and Toughness: Can meet ANSI/BHMA Grade 1 requirements.

- Wide Temperature Tolerance: Stable performance at high and low temperatures.

- Easy to Clean, Low Maintenance: Dense surface, not easily contaminated.

- Modern Appearance, Strong Hygienic Feel.

Limitations of Stainless Steel Paddle Latches

- High Cost: Double high in raw material and processing expenses.

- High Processing Difficulty: High hardness, difficult to form, high cost for complex shapes.

- Limited Finish Options: Mostly brushed, mirror, or PVD colors, with high PVD cost.

Zinc Alloy

What is Zinc Alloy?

Zinc alloy is mainly zinc, with added elements such as aluminum (Al), copper (Cu), magnesium (Mg). Locks mostly use die-casting process for forming. Common grades include Zamak 3 and Zamak 5 (Specifications: ASTM B86, GB/T 13818-2024).

Core Advantages of Zinc Alloy Paddle Latches

- Excellent Plasticity and Dimensional Accuracy: Die-casting can achieve complex shapes.

- Diverse Surface Treatment Capabilities:

- Electroplating (such as chrome, nickel, imitation brass color), reference ISO 2081 or ASTM B633;

- Spraying (multiple colors);

- PVD Finishes (for high-end appearance).

- Good Cost-Effectiveness: Cheap raw materials, high production efficiency.

- Moderate Strength: Can meet residential and commercial indoor occasions (Grade 2 or Grade 3).

Limitations of Zinc Alloy Paddle Latches

- Corrosion Resistance Depends on Coating: Base material itself prone to oxidation.

- Coating Easily Damaged: Once scratched, exposed zinc will oxidize to form white rust.

- Insufficient Toughness: Prone to brittle fracture under high impact, not suitable for Grade 1 high-security levels.

- Higher Density, Solid Hand Feel: Weight close to stainless steel, can be optimized through wall thickness in design.

Plastic (Plastic)

What is the “Plastic” Used in Locks?

The “plastic” here refers to engineering plastics (Engineering Plastics), which have mechanical and thermal properties superior to ordinary plastics.

| Material | Standard Reference | Key Properties | Typical Advantages / Notes |

|---|---|---|---|

| ABS | ASTM D4673 | Good impact resistance, smooth surface | Balanced strength and aesthetics; easy to mold |

| Nylon PA66 | ASTM D4066 | Wear-resistant, self-lubricating | Commonly used for silent or moving components |

| Polycarbonate (PC) | ISO 7391 | Extremely high impact strength | Excellent clarity and toughness; used in safety-critical parts |

| PVC | ASTM D1784 | Chemical-resistant, low cost | Economical choice for corrosion-prone environments |

Core Advantages of Plastic Paddle Latches

- Low Cost, High Efficiency: Injection molding suitable for mass production.

- Corrosion-Resistant to Water and Most Inorganic Chemicals.

- Significant Lightweighting.

- Good Electrical Insulation: Suitable for electrical cabinets and distribution boxes.

- Diverse Colors: Colors are inherent to the material, no need for post-coating.

Limitations of Plastic Paddle Latches

- Low Strength: Cannot meet ANSI/GB security grade requirements.

- Limited Wear Resistance and Fatigue Life.

- Sensitive to UV and High Temperatures: Need to add anti-UV agents to delay aging.

- Not Resistant to Some Organic Solvents (such as acetone), Lighter Feel.

Horizontal Comparison: Stainless Steel vs. Zinc Alloy vs. Plastic

| Comparison Dimension | Stainless Steel (SUS316) | Stainless Steel (SUS304) | Zinc Alloy (High-Quality Coating) | Plastic (Engineering Plastic) | Evaluation Basis / Remarks |

|---|---|---|---|---|---|

| Security Strength | Extremely High | High | Medium | Extremely Low | ANSI/BHMA A156.x; Stainless steel can reach Grade 1, zinc alloy Grade 2–3. |

| Corrosion Resistance | Extremely High (Resistant to Chlorides) | High | Low | High (to Water / Most Chemicals) | 316 contains molybdenum resistant to salt spray; 304 not resistant to chloride ions. |

| Wear Resistance | High | High | Medium (Depends on Coating) | Low | Electroplating or PVD can increase surface hardness. |

| Weather Resistance | Extremely High | Extremely High | Low | Medium (Needs Anti-UV Agents) | Zinc alloy coatings are prone to aging and oxidation. |

| Design Flexibility | Low | Low | Extremely High | High | Die-casting and injection molding enable complex geometries. |

| Appearance Diversity | Low | Low | Extremely High | High | Zinc alloy supports chrome plating, powder coating, or painting. |

| Manufacturing Cost | High | High | Medium | Low | Based on combined material and processing expenses. |

| Weight | High | High | Medium-High | Low | Plastic offers significant weight reduction. |

| Maintenance Requirements | Low | Low | High | Low | Zinc alloy performance depends on coating integrity. |

Key Performance Showdowns

Security Showdown: Stainless Steel > Zinc Alloy > Plastic

Stainless steel has high toughness and strong resistance to damage, zinc alloy meets medium security needs, plastic has no anti-theft properties.

Weather Resistance Showdown: 316 Stainless Steel > 304 Stainless Steel > Plastic > Zinc Alloy

316 suitable for coastal high-salt environments, 304 for regular outdoor, zinc alloy not recommended for outdoor use.

Design and Aesthetic Showdown: Zinc Alloy > Plastic > Stainless Steel

Zinc alloy die-casting can achieve extremely high shape freedom, is the first choice for decorativeness. Stainless steel leans more toward industrial style.

Application Scenarios and Selection Guide

Residential Front Doors and High-Security Places

- Recommended: 304/316 Stainless Steel.

- Reason: Meets high strength and corrosion resistance.

Residential Interior Doors (Bedrooms, Studies)

- Recommended: Zinc Alloy.

- Reason: Diverse shapes, high cost-performance.

Bathrooms, Kitchens, Coastal Residences

- Recommended: 316 Stainless Steel (Coastal) or 304 (Regular Wet Areas).

- Reason: High humidity and salinity environments have extremely high corrosion requirements.

Storage Cabinets, Toolboxes, Low-Security Areas

- Recommended: Engineering Plastic or Low-Cost Zinc Alloy.

- Reason: Low security requirements, focus on lightweight and cost.

Specific Industrial Applications

Electrical Cabinets: Plastic (Insulation)

Ships: 316 Stainless Steel (Compliant with ISO 3506 A4 Level)

Risk of Electrochemical (Galvanic) Corrosion

When evaluating a single material, we focus on its own corrosion resistance. But in actual applications, paddle latches are an “assembly,” inevitably contacting different metals such as fasteners (screws), door panels (substrates). At this point, a more hidden killer—electrochemical corrosion—becomes the primary threat.

What is Electrochemical Corrosion?

When two metals with significant differences in electrochemical potential (“metal activity”) contact each other in the presence of an electrolyte (such as moisture, rainwater, salt spray), they form a micro-battery.

- The metal with higher activity (lower potential) becomes the anode (Anode), accelerating corrosion (being “sacrificed”).

- The metal with lower activity (higher potential) becomes the cathode (Cathode), receiving protection.

Simplified Potential Sequence Applicable to Locks

For the materials we discuss, a simplified activity (corrosion risk) ranking is as follows:

- Anode (Most Easily Corroded)

- Zinc Alloy (Zamak)

- Aluminum Alloy (Aluminum)

- Cathode (Least Easily Corroded / Noble Metals)

- Stainless Steel (Stainless Steel – 304/316)

(Note: Engineering plastics are electrical insulators and do not participate in electrochemical corrosion.)

The Biggest Trap in Procurement: High-Risk Combinations

The severity of electrochemical corrosion depends on the surface area ratio of the anode (corroded) and cathode (protected). The worst case is “small anode large cathode”—a small piece of active metal contacting a large piece of inert metal.

High-Risk Case (Should Be Extremely Avoided):

“Stainless Steel Screws + Zinc Alloy Handle + Aluminum Door Panel”

This is a very disastrous combination in outdoor or humid environments.

Analysis: Zinc alloy (anode) contacts both stainless steel (cathode) and aluminum (different potentials). In moisture, zinc alloy acts as anode, “sacrificing” itself to protect stainless steel and aluminum.

Result: Zinc alloy handle will quickly show coating bubbling, white rust (zinc oxide), and soon structural corrosion failure, even though stainless steel screws and aluminum door panel remain intact.

How to Prevent Electrochemical Corrosion in Procurement and Design?

First Choice: Material Matching

- Use materials with close potentials as much as possible. For example: Stainless steel lock body + stainless steel fasteners.

- Or, use plastic components, as their natural insulation fundamentally eliminates galvanic corrosion.

Key: Electrical Isolation (Isolation)

- If different potential metals must be used (e.g., installing stainless steel lock on aluminum door panel), electrical isolation must be performed between them.

- Procurement Requirement: The lock must be equipped with (or the purchaser must separately use) non-conductive washers, bushings, or sealants (such as nylon, rubber, Teflon gaskets) to ensure no direct electrical path between different metals.

Secondary Choice: Complete Coating

- Use powder coating or thick paint layers to completely isolate the entire component (especially anode parts) from the electrolyte (moisture).

- Risk: This protection completely depends on the coating’s integrity. Once the coating is scratched or damaged, corrosion will rapidly concentrate at the damage point, leading to faster local failure.

Procurement Checklist: 6 Questions to Confirm Before Purchase

- Is the usage environment indoor or outdoor?

- Is there high humidity or corrosiveness (such as coastal, bathrooms)?

- Does the security grade need to comply with ANSI/GB standards?

- Does it need to match a specific decorative style?

- What is the budget limit?

- (New) Assembly Compatibility: What materials will the lock contact (fasteners, door panels)? Is electrical isolation (such as washers) needed?

Maintenance and Care

Stainless Steel Locks

Clean with soft cloth and neutral cleaner, avoid chlorine-containing solutions.

Zinc Alloy Locks

Avoid scratching the coating, prevent corrosion.

Plastic Locks

Avoid strong solvents, store away from sun.

Conclusion: Correct Choice Based on Application

- Stainless Steel: Long-term investment in strength and durability.

- Zinc Alloy: Practical solution balancing design and cost.

- Plastic: Economic solution for specific low-load or insulation applications.

There is no absolute superiority or inferiority in materials, only the most matching application. Procurement should be based on usage environment, security grade, and assembly compatibility, and require suppliers to provide material reports, ANSI/BHMA test data, and ISO 9227 salt spray test reports to ensure decisions are based on verifiable engineering standards.

FAQ

Q1: Will 304 Stainless Steel Rust at the Seaside?

A: Yes. 304 does not contain molybdenum, chloride ions can destroy the passivation film, leading to pitting. Coastal should choose 316.

Q2: How to Distinguish Stainless Steel Locks from Zinc Alloy Locks?

A: Stainless steel usually shows original metal color, with cutting marks on edges; zinc alloy mostly has electroplated or sprayed surfaces, revealing gray-white substrate after peeling. Can require supplier to provide material test report (MTR).

Q3: Why Do Zinc Alloy Locks Bubble or Peel?

A: Because after coating damage, the zinc substrate is corroded (or galvanic corrosion occurs), oxides expand and lift the coating. Especially common in high-humidity environments.