HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Although electrical cabinet door hinges are often viewed as inconspicuous “Class C components” in the Bill of Materials (BOM), they directly relate to the safety, sealing rating (IP Rating), and long-term durability of expensive cabinet systems.

In industrial settings, without reliable hinge support, heavy cabinet doors are prone to sagging, leading to closure failure or seal compromise, which in turn endangers the operating environment of internal equipment. Traditional external hinges (surface-mounted) present obvious pain points:

- Security Risks: Exposed pins make them easy to pry open or disassemble.

- Aesthetic Defects: They protrude from the cabinet body, easily accumulating dust and ruining the overall industrial design.

- Maintenance Difficulties: Once the door panel sags due to gravity, traditional hinges offer almost no room for adjustment.

The emergence of Adjustable Concealed Hinges (3D Adjustable Concealed Hinges) has solved these problems. Installed inside the door panel and cabinet frame, they are not only anti-theft and aesthetically pleasing, but their core advantage lies in their three-dimensional adjustment capability—allowing for fine-tuning of the door panel position even after installation.

This guide will combine industry standards (IEC, EN, UL) and practical applications to provide you with a detailed selection and purchasing strategy.

Why Upgrade to “Adjustable Concealed Hinges”?

Before deciding on a selection, we need to clarify the four core values these hinges bring:

Ultimate Security and Anti-Vandalism

Concealed installation means that when the cabinet door is closed, the hinge body is completely hidden inside the cabinet. There are no accessible pins or screws on the outside, making it impossible for attackers to disassemble the hinge from the exterior. This is crucial for outdoor telecom cabinets, ATMs, or control cabinets storing high-value equipment.

Enhanced IP Protection Rating (Waterproof and Dustproof)

Traditional external hinges require cutting the sealing strip at the door edge, creating a break point in the seal. Concealed hinges, however, are installed on the inner side of the door, allowing the sealing strip around the door frame to remain continuous and intact. This makes it easier for the cabinet to achieve IP65/IP66 protection ratings (dustproof and protection against powerful water jets), effectively preventing the intrusion of rain and dust.

Three-Dimensional (3D) Adjustment Capability: Tolerance and Correction

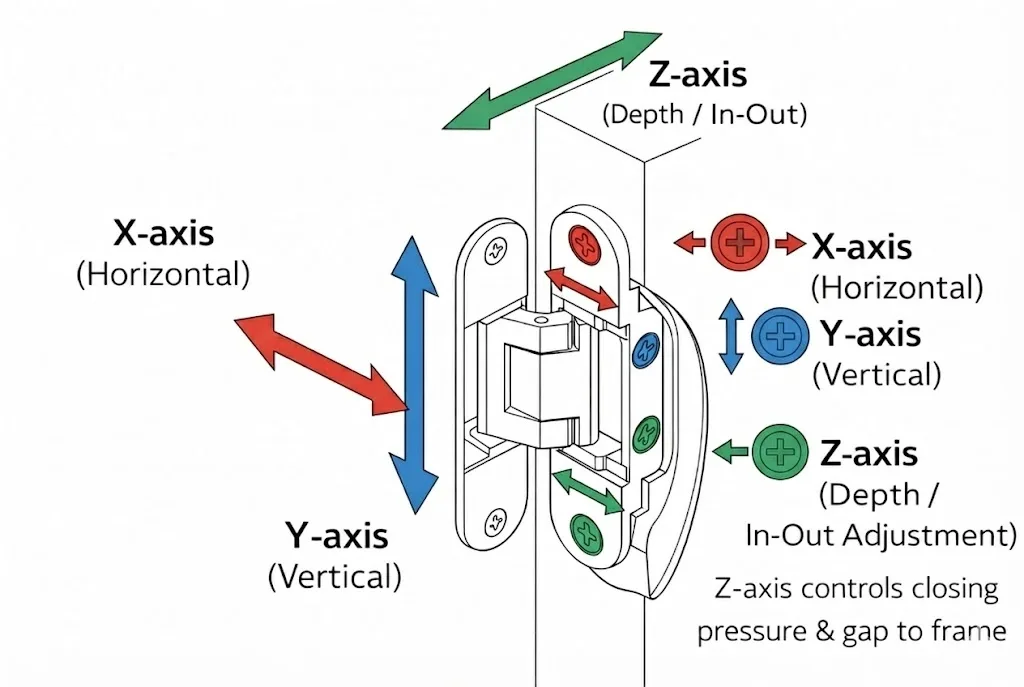

This is the “killer feature” of this type of hinge. Through the built-in adjustment mechanism, installers can correct the door panel position in three directions:

- X-axis (Horizontal): Adjusts the left and right gap of the door.

- Y-axis (Vertical): Solves the problem of door panel sagging.

- Z-axis (Depth): Adjusts the compression force of the sealing strip.

Compliant with Modern Industrial Aesthetics and Standards

The concealed design leaves the cabinet surface flat and smooth, which is not only aesthetically pleasing but also reduces dead corners for cleaning. Additionally, high-end concealed hinges make it easier for the entire cabinet to pass international certifications such as EN 1935 (Durability) and UL 50E (Outdoor Safety).

5 Core Selection Indicators (Key Technical Details)

When purchasing, be sure to evaluate against the following five indicators.

Adjustment Capability (3D Adjustment)

Do not just look at whether it is “adjustable,” but look at the “adjustment range” and “operational convenience.”

- Functional Analysis: High-quality hinges allow adjustment by simply turning a screw with an Allen wrench (hex key) without disassembling the door panel.

- Recommended Metrics: Look for products that provide an adjustment range of at least ±1.5mm to ±3mm in all three directions (X/Y/Z).

- Practical Significance: It can perfectly compensate for sheet metal processing errors (tolerances) and quickly fix door panel sagging caused by gravity after years of use.

Load Capacity

Insufficient load capacity is the primary cause of mechanical failure and hinge breakage in industrial enclosures. To ensure long-term reliability, selection must account for both static weight and dynamic stress.

- Single Load vs. System Load: Manufacturers typically specify “rated load per hinge” or “load per pair.” When calculating requirements, it is an engineering best practice to maintain a safety margin of 25%–30%. This buffer accounts for material fatigue and minor installation misalignments over the product’s lifecycle.

- The Leverage Effect & Dynamic Loads: The actual stress on a hinge is not merely a function of weight but of Torque = Force × Distance (M = F × d). If a door is exceptionally wide, the increased distance ($d$) from the center of gravity to the hinge axis multiplies the leverage effect.

- Calculation Adjustment: For doors exceeding standard widths (e.g., >800mm) or those equipped with door closers and wind stops, the effective load should be calculated at 1.5 times the actual door weight to compensate for these dynamic forces.

- Standard Reference: Refer to ANSI/BHMA A156.1 for weight-to-width ratio guidelines to ensure compliance with North American hardware standards.

- Strategic Quantity Configuration:The number of hinges is determined by door height and structural stability, not just total weight:

- Door height < 1.5m, weight < 40kg: 2 Hinges are generally sufficient.

- Door height > 1.8m, or weight > 60kg: 3 or 4 Hinges are required.

- Expert Tip: Placing an additional hinge near the top (where tensile stress is highest) or at the midpoint effectively prevents the door panel from “bowing” or warping, ensuring the integrity of the IP seal across the entire vertical edge.

Material and Corrosion Resistance

Choose the material according to the application environment; never sacrifice corrosion protection to save money.

- Stainless Steel — The First Choice for Outdoors and Harsh Environments

- 304 Stainless Steel: Suitable for most outdoor cabinets and general chemical plants, with excellent weather resistance.

- 316 Stainless Steel: Contains Molybdenum, offering extremely strong resistance to chloride ion corrosion. Must be used in coastal areas, offshore platforms, and strong acid/alkali workshops.

- Zinc Alloy — Indoor and General Environments

- Commonly used in indoor control cabinets. Through chrome plating or black powder coating, it offers an exquisite appearance and moderate cost. Confirm that it passes at least a 96-hour neutral salt spray test.

- Carbon Steel — High Strength Heavy Duty

- High strength but prone to rust, usually treated with galvanization or Dacromet. Only recommended for heavy-duty equipment in dry indoor environments.

Standard Reference: For outdoor cabinets, it is recommended to require hinges that comply with EN 1670 Grade 4 (Very high corrosion resistance, no red rust after 240 hours of salt spray).

Opening Angle

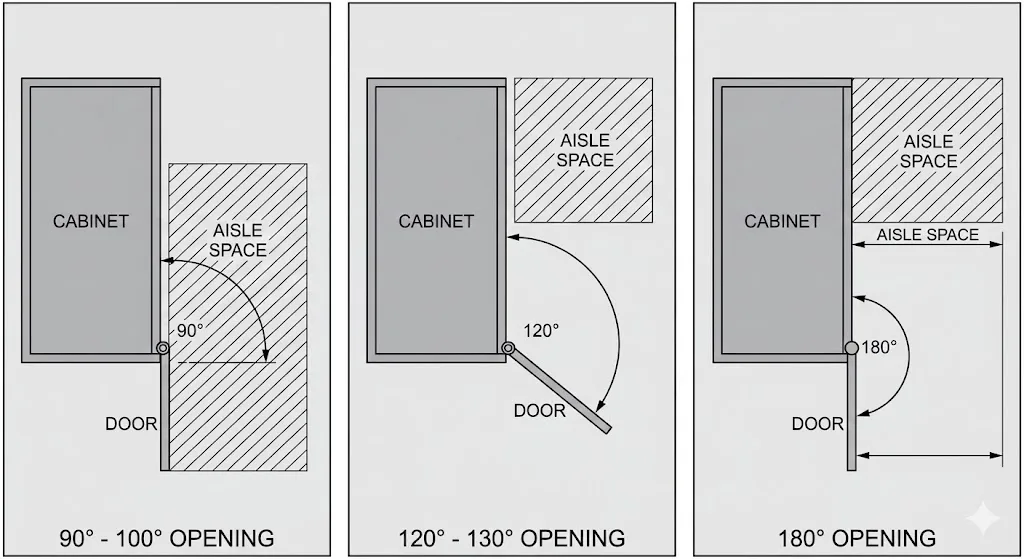

- 90° – 100°: Suitable for cabinets placed against a wall or in corridors with limited space.

- 120° – 130°: The most universal choice. It ensures maintenance personnel have enough operating space without blocking the aisle by opening the door too wide.

- 180°: Allows the door panel to flip completely open and flush against the side of the cabinet. Suitable for scenarios with narrow aisles but requiring full-width access (such as server cabinets). Note: Achieving a 180° opening usually requires a more complex hinge structure and higher cost.

Installation Method: Weld-on vs. Screw-on

- Screw-on:

- Pros: Easy installation, easy to replace and maintain, suitable for assembly after painting.

- Cons: Requires precise pre-drilled holes, risk of screws loosening (requires thread-locking adhesive or washers).

- Weld-on:

- Pros: Extremely high connection strength, suitable for ultra-heavy doors. No exposed screw holes, better sealing.

- Cons: Non-removable, difficult to replace; welding heat may cause door panel deformation; rust protection must be redone after welding.

- Hybrid: Welded on the frame side, screwed on the door side. Balances strength with ease of disassembly, making it a preferred choice for heavy industrial cabinets.

Special Section: Electrical Continuity and Grounding (EMC)

In electrical cabinet design, a point often overlooked is the conductivity of the hinge.

To comply with Electromagnetic Compatibility (EMC) and safety grounding standards, the cabinet door must maintain a good electrical connection with the cabinet body.

- Problem: Many concealed hinges come with plastic bushings (for silence and wear resistance) or have insulated surfaces due to powder coating, causing insulation between the door and the cabinet body.

- Solution:

- Select specialized hinges with grounding components (such as paint-piercing washers that can cut through the paint layer to conduct electricity).

- Install an additional grounding braided copper strap between the door and the cabinet body.

- Recommendation: Regardless of whether the hinge is conductive, for high-voltage cabinets or sensitive control cabinets, it is always recommended to install independent flexible grounding copper wires to ensure absolute safety.

Analysis of Typical Industry Application Scenarios

| Industry Scenario | Key Challenges | Recommended Selection Scheme |

| Outdoor Telecom / 5G Base Station | Sun exposure, rain, theft risk, coastal salt spray | Material: 316 Stainless Steel Function: Fully concealed anti-pry Protection: Must reach IP65 with sealing strips |

| Industrial Automation (PLC Cabinet) | Extremely high frequency of opening (multiple times a day), vibration | Material: Zinc Alloy or 304 Stainless Steel Lifespan: Must pass 100,000+ cycle test Function: Must have 3D adjustment to correct sagging |

| High/Low Voltage Switchgear | Extremely heavy door panels, anti-explosion requirements, safety first | Material: High-strength Alloy Steel (Weld-on) Configuration: 3-4 hinges per door Certification: Must comply with power industry anti-seismic and anti-shock standards |

Practical Suggestions for Installation and Maintenance

To ensure the hinge performs at its best, please follow these specifications:

Gap Calculation:When designing the sheet metal structure, be sure to reserve installation space by referring to the hinge specification sheet. It is generally recommended to reserve a gap of 2-3mm between the door and the frame. This ensures the sealing strip is compressed by 30%-50% (optimal sealing effect) while preventing metal scraping when opening the door.

Anti-Loosening Measures:For screw-mounted hinges, since cabinets are often subject to micro-vibrations, be sure to use thread-locking adhesive (Loctite) or spring washers. Loose screws are the primary cause of door panel sagging.

Adjustment Sequence:

- Adjust the vertical screw (Y-axis) to align the door height.

- Adjust the horizontal screw (X-axis) to correct for even left and right gaps.

- Adjust the depth screw (Z-axis) to test the closing force, ensuring the sealing strip is compressed but the door is not too difficult to close.

Regular Lubrication:Check the hinge pivot every 6-12 months. If it is a metal-to-metal friction pair, add a small amount of lubricating oil; if it uses engineering plastic bushings, it is usually a maintenance-free design, so do not add oil arbitrarily to avoid attracting dust.

FAQ

Q: Can concealed hinges support a cabinet door weighing over 100kg?

A: Absolutely. Heavy-duty concealed hinges are designed specifically for heavy loads, bearing weight through multi-link or thick-walled structures. For doors over 100kg, it is recommended to use weld-on installation and configure 3-4 hinges to distribute the stress.

Q: How do I determine if I need 316 Stainless Steel?

A: If your equipment is installed seaside (within 5km of the coastline), on an offshore platform, in a sewage treatment plant, or inside a chemical plant, please be sure to use 316. Ordinary 304 will show pitting (rust spots) within just a few months in these environments.

Q: Can I convert an existing old cabinet with external hinges to concealed hinges?

A: It is relatively difficult. Concealed hinges usually require specific installation space or bending structures inside the door frame. If retrofitting is necessary, it may require sheet metal cutting and re-welding of the door panel and frame, which incurs high costs. It is recommended to implement this directly when designing new products.

Conclusion

Choosing an electrical cabinet hinge is not just about buying a connection part; it is about purchasing long-term safety insurance for your equipment.

Although the initial cost of adjustable concealed hinges is slightly higher than traditional external hinges, the stability of IP protection, installation tolerance, and high-end aesthetic value they bring can significantly reduce the Total Cost of Ownership (TCO) of the equipment. In the context of today’s pursuit of high-quality manufacturing, a good hinge is often the detail that distinguishes a high-end cabinet from a low-end metal box.

-768x768.png)