HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Essential elements in various Industrious applications, industrial stainless steel draw latches, provide Safe and long-lasting closures for Equipment, cabinets, etc..Famous for their Resistance to Stressful environmental situations and ability to Endure the challenges of Industrious application, these latches are.

Exploring the Principal qualities, Advantages and applications of industrial stainless steel draw latches, this article highlights four Necessary requirements that must be met to ensure optimal performance.As for Corrosion and environmental stress resistance, it is one of the Necessary requirements.For industrial stainless steel draw latches, one of the primary demands is their ability to resist corrosion and environmental stress.

Exposed to Severe temperatures, Moisture, and Corrosive agents in many industrial settings, latches are.Thus, they must be made from Premier stainless steel that can withstand these conditions Without deterioration.In terms of sturdiness and strength, it is another essential demand.Substantial loads and Repetitive operation are often required for latches in Industrious applications.

For ensuring long-term performance, the resilience and robustness of stainless steel pull latches are crucial.As for tailoring and adaptability, it is a further essential demand.For commercial-grade stainless steel pull latches, another demand is their customizability to meet particular needs.

Adjusting the dimensions, form, and characteristics of the latch to fit diverse applications includes.As for simple installation and upkeep, it is a final essential demand.Easy to install and maintain, commercial-grade stainless steel pull latches should minimize down time and workforce expenses.Featuring detailed installation guidance and being equipped with exchangeable or fixable parts, a excellently engineered latch should.

In the following sections, these demands will be explored in more detail, and the advantages of employing commercial-grade stainless steel pull latches in diverse applications will be discussed.As for corrosion resistance resistance and ambient tension, we will explore this in more detail in the initial part. Designed to withstand severe environmental circumstances, commercial-grade stainless steel pull latches are.

Their premium stainless steel composition ensures that they can withstand corrosion, oxidation, and wear, caused by exposure to humidity, substances, and extreme conditions.To meet this demand, manufacturers use stainless steel mixtures that are specifically formulated to provide exceptional anti-corrosion protection.

Due to its excellent resistance to chloride corrosion, making it perfect for naval surroundings, 316-grade stainless steel is a popular choice.In the section that follows, the second essential demand, which is resilience and fortitude, will be discussed.Engineered to provide exceptional resilience and fortitude, commercial-grade stainless steel sliding locks are.

Designed to withstand extensive weights and consistent usage, making them suitable for uses in production, building, and logistic sectors, they are.To ensure durability, industrial latches are subjected to rigorous testing, including tensile resistance, resilience to shocks, and endurance examinations.

Next, we will delve into the third critical requirement, which is tailoring and compatibility.available in various dimensions, shapes, and configurations, heavy-duty stainless steel drawers latches allow for tailoring for fulfillment tailored operational needs.offerrs offer a variety of choices for personalization, including multiple locking mechanisms, various handle types, and fixing equipment.

Finally, we turn to the fourth critical requirement, which is simple installation and upkeep.In the selection of heavy-duty stainless steel drawers latches, installation convenience and maintenance ease is a key aspect.A well-designed latch should feature detailed directions and easily installable parts and replace.

Many heavy-duty stainless steel drawers latches come with automatic latching systems that require least effort to secure or release.In conclusion, being an essential component in various industrial applications, heavy-duty stainless steel drawers latches offer safe and sturdy sealing options.By meeting demands such as corrosion resistance, longevity, customization, and installation convenience, these latches offer a dependable and economic solution for industrial environments.

Recommend three widely draw latches

Safe Door Latch Buckle SK308, made of stainless steel with vibrated finish, is mainly used for safes, car compartments, tin cabinets and so on.

Spring Loaded Draw Latches DK605, made of stainless steel with a polished surface. They are used in car compartments, drawers and equipment cases.

Adjustable Draw Latches DK027, made of stainless steel with vibrated surface treatment, are of surface mounted type with adjustable length of 50-65mm, mainly used for marine cabinets, heavy equipment, PC cabinets, Rittal cabinets etc.

Classification of industrial stainless steel latches

| Classification method | Specific classification | Features and application scenarios |

| Classification by structural form | ordinary Draw Latches | The product consists of a hook and latch, featuring a simple structure and easy operation. It is suitable for general industrial equipment boxes, toolboxes, and similar applications |

| concealed Draw Latches | After installation, most of the structure is hidden, providing a neat appearance and protecting against external collisions and damage. It is commonly used for enclosures of industrial instruments or equipment control cabinets that require a high aesthetic standard. | |

| Rotary Draw Latches | The hook or fastening ring can rotate around the shaft, allowing for flexible opening and closing, with adjustable angles. It is suitable for folding industrial display racks and similar applications | |

| heavy duty Draw Latches | The structure is robust, made from thick stainless steel material, and features large dimensions. It is designed to withstand high tension, pressure, and impact, commonly used for large industrial equipment doors, hatch doors, and similar applications. | |

| Classification by fastening method | spring-loaded Draw Latches | The interior is equipped with a spring mechanism, making fastening and opening easier. It is ideal for environments where frequent opening and closing is required, such as small tool cabinets next to industrial production lines |

| push Draw Latches | Fastening and opening are achieved by pressing a specific button or area, making the operation simple and quick, and allowing for one-handed use. It is commonly used in equipment that needs to be quickly accessed in emergencies, such as fire safety equipment boxes | |

| Classification by Functional Characteristics | anti-theft Latches | It features a anti-theft design, such as a special lock cylinder or keyhole, requiring a specific key to open. It is commonly used for industrial safes, hazardous chemical storage cabinets, and similar applications where valuable or dangerous items are stored |

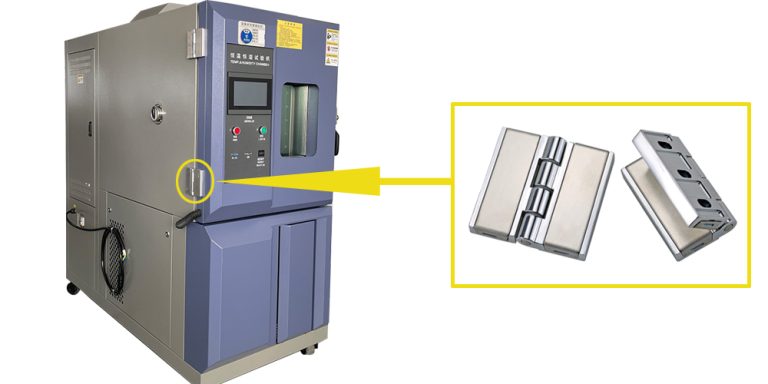

| sealing Draw Latches | The edges or areas in contact with objects have a sealing structure, such as rubber seals, which prevent dust, moisture, gases, and other contaminants from entering. It is suitable for industrial equipment that requires strict environmental control, such as sealed boxes for food processing equipment or sealed chambers for electronic chip manufacturing equipment. | |

| adjustable Draw Latches | The fastening tightness or connection length is adjustable, allowing it to accommodate objects of varying thicknesses or different operating environments. It is commonly used in high-end machinery and precision equipment. |