HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Paddle latches—recessed, hand-operated latches often featuring a flip-out paddle mechanism—are ubiquitous in industrial, transportation, and consumer applications. From toolbox lids on service vehicles to access panels on electrical enclosures, paddle latches combine ergonomic design, robust construction, and secure operation.

This comprehensive guide delves into every aspect of paddle latches: their history, types, components, materials, installation methods, applications, maintenance, selection criteria, and future trends.

What Is a Paddle Latch?

A paddle latch is a flush-mounted latch mechanism featuring a recessed paddle handle that pivots outward when actuated. When released, an internal spring or cam mechanism snaps the paddle back into the recess, locking the door or panel in place. This “push‑to‑close, pull‑to‑open” operation offers:

- Flush Profile: Minimizes snagging and enhances aesthetics.

- Ergonomic Operation: Paddle handle provides ample leverage.

- Secure Closure: Internal cams or wedging surfaces prevent unintentional opening.

Historical Evolution

Originally designed for heavy‑duty military and transportation equipment in the mid‑20th century, paddle latches evolved from simple cam latches. Early versions lacked paddle handles and relied on rotary knobs. The advent of recessed paddles in the 1970s improved safety by reducing protrusion, leading to wide adoption in RVs, boats, and service trucks.

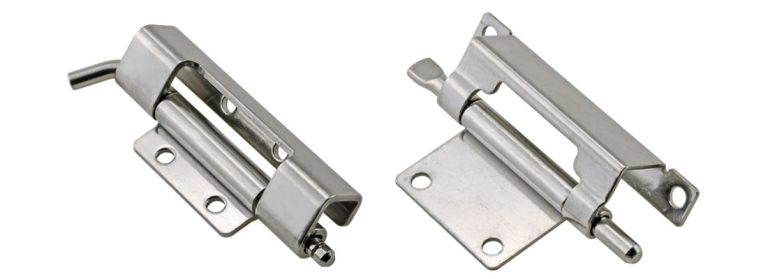

Key Components

| Component | Function |

|---|---|

| Paddle Handle | User interface; flips out to actuate the latch mechanism. |

| Recessed Housing | Encases internal latch mechanism and provides a flush mount. |

| Cam or Bolt | Engages with striker plate or receiver to secure the door/panel. |

| Spring Mechanism | Returns paddle to the flush position upon release. |

| Gasket | Weather‑seals the housing in outdoor applications. |

| Key Cylinder (Optional) | Enables lockable versions for security-critical applications. |

Types of Paddle Latches

Non‑Locking Paddle Latches

Basic form featuring a spring-loaded cam; ideal for applications where security is not paramount (e.g., interior access panels).

Key‑Locking Paddle Latches

Integrate a lock cylinder to prevent unauthorized access; commonly used on truck toolboxes, electrical cabinets, and marine hatches.

Rod‑Controlled Paddle Latches

Allow cables or rods to connect multiple latches for remote operation or multi‑point locking systems; prevalent in industrial enclosures and emergency vehicle compartments.

Back‑to‑Back Multi‑Point Latches

Feature paddle handles on both sides of a panel, enabling locking/unlocking from either side and multi‑point engagement via rods or cables.

Materials and Finishes

| Material | Characteristics | Typical Finishes |

|---|---|---|

| Stainless Steel | High corrosion resistance; marine‑grade options | Brushed, polished, electropolished |

| Zinc‑Plated Steel | Cost‑effective; moderate corrosion resistance | Zinc plating with chromate trivalent passivation |

| Powder‑Coated Steel | Enhanced corrosion protection; color customization | Textured, matte, or glossy |

| Plastic/Composite | Lightweight; non‑corrosive; limited load capacity | Black or gray textured |

Applications Across Industries

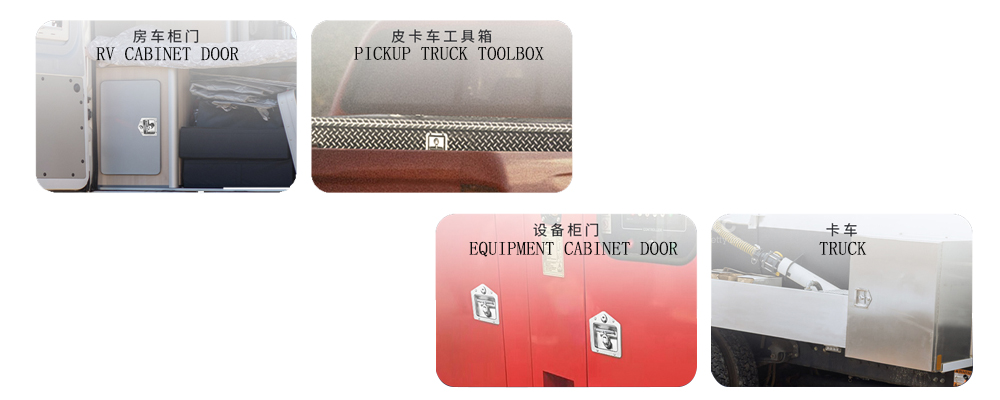

- Commercial Vehicles: Toolbox lids and compartment doors on service trucks, step vans, and utility vehicles.

- Recreational Vehicles: RV entrance doors and storage bays with lockable, weather-resistant paddle handles.

- Marine: Flush-mount stainless steel paddle latches on hatches and lockers.

- Electrical Enclosures: Keyed push-to-close paddle locks for control panels.

- Consumer Products: Plastic paddle latches in furniture, gaming cabinets, and vending machines.

Installation Guidelines

- Cut‑Out Preparation: Follow manufacturer’s template for precise recess dimensions.

- Sealing: Apply gasket or silicone sealant for weatherproofing.

- Mounting: Insert latch, align bolt/cam with striker plate, and secure with screws.

- Adjustment: Tighten or shim as necessary to ensure smooth paddle action and reliable engagement.

Maintenance Best Practices

- Regular Cleaning: Remove debris and corrosion-prone residue.

- Lubrication: Apply light machine oil to moving parts annually.

- Gasket Inspection: Replace worn gaskets to maintain weather sealing.

- Lock Servicing: Use graphite powder in keyed versions to prevent cylinder wear.

Selecting the Right Paddle Latch

| Criterion | Questions to Ask |

|---|---|

| Environment | Will it face salt spray, dust, or chemicals? |

| Security Level | Is key‑locking or padlockable function needed? |

| Load Requirements | What force must the latch withstand? |

| Aesthetics | Should finish match panel color or style? |

| Operation | Single‑point vs. multi‑point engagement? |

Case Study: Fleet Service Trucks

A national utility company retrofitted 200 service trucks with rod‑controlled stainless steel paddle latches, enabling quicker access to ladder compartments and toolboxes. The new latches reduced service time by 15% and lowered latch‑related maintenance calls by 40%.

Future Trends

- Smart Latches: Integration of RFID and Bluetooth for keyless entry and remote monitoring.

- Lightweight Composites: Use of high‑strength polymers to reduce weight in transport applications.

- Enhanced Sealing Technologies: Advanced gasket materials for improved environmental resistance.

FAQ

Q1: Can paddle latches be customized?

Yes—many manufacturers offer custom cut‑outs, logo embossing, torque settings, and specialty finishes.

Q2: What cut‑out dimensions are standard?

Common recess sizes range from 3″×3″ to 5¾″×4¾″, but custom dimensions are available.

Q3: Are there padlockable versions?

Most key‑locking paddle latches can be equipped with padlock hasps or integrated padlocking mechanisms.

Conclusion

Paddle latches marry ergonomic design with mechanical reliability, making them indispensable across multiple industries. By understanding their types, materials, installation, and maintenance, specifiers and end‑users can maximize performance and longevity. Whether you’re outfitting a service fleet, designing an electronics enclosure, or securing an RV door, selecting the right paddle latch ensures seamless operation and peace of mind.