HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

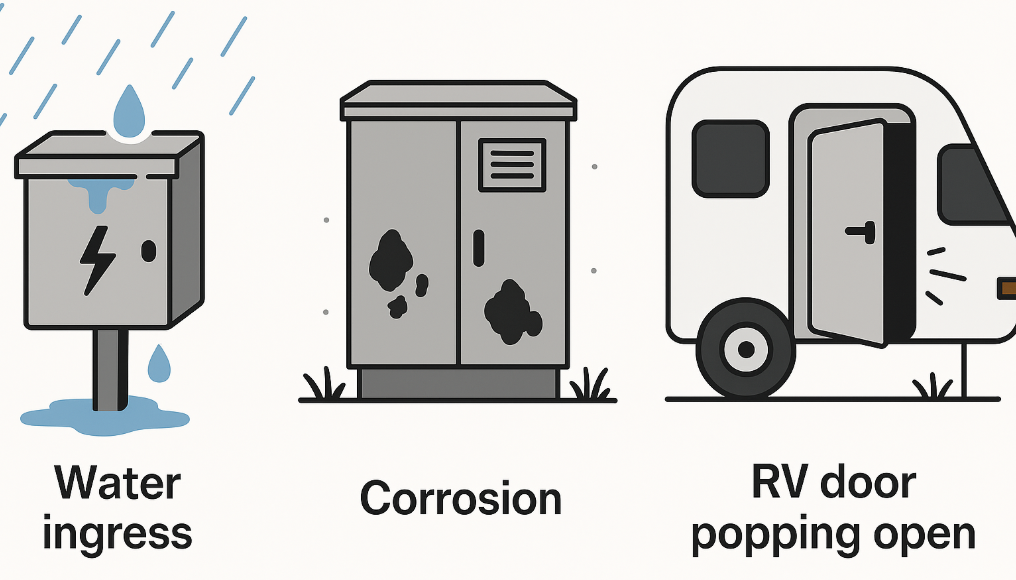

Many outdoor equipment failures aren’t caused by the enclosure itself, but by the often-overlooked “small handle.”

Water ingress in power boxes, corrosion in communication cabinets, RV doors popping open during driving—all these issues share the same cause: “Locks that secure the door, but not the environment.”

In working conditions involving rain, salt spray, UV exposure, and strong vibration, a qualified outdoor Paddle Latch must not only close the door but also provide reliable sealing compression, corrosion resistance, vibration resistance, and anti-theft performance.

This guide explains—from principles to materials to selection—what kind of “stronger Paddle Latch” outdoor and harsh environments truly require.

Why Outdoor and Harsh Environments Need “Stronger Paddle Latches”

Outdoor Paddle Latches perform two tasks:

Lock the door, and lock out the environment.

Typical scenarios include:

- Outdoor power distribution boxes / control cabinets

- Communication cabinets, 5G base station equipment enclosures

- RVs, camper trailers, pickup truck toolboxes

- Marine hatches, dock equipment boxes

- Jobsite anti-theft toolboxes, waterproof instrument cases

These devices share several characteristics:

- Long-term exposure to rain, UV, dust, sand, salt spray

- Frequent opening and closing, sometimes with vehicle vibration or marine impact

- Enclosures often carry electrical equipment, control systems, communication modules, measurement instruments—any water ingress, corrosion, or loosening can cause major losses.

“Harsh environment” may include:

- Temperature: below -40°C to above +80°C

- Humidity: year-round high humidity and condensation

- Corrosion: coastal salt spray, chemical plant acidic/alkaline vapors

- Mechanical: constant vibration in vehicles, heavy machinery, generator boxes

- Climate: high UV, snow load, freezing, sandstorms

A Paddle Latch that merely “closes the door” is far from sufficient.

A well-designed outdoor Paddle Latch must simultaneously provide:

- Sealing compression force

- Long-term corrosion resistance

- Vibration resistance and anti-loosening

- Anti-theft and anti-prying protection

Basic Concepts and Working Principles of Paddle Latches

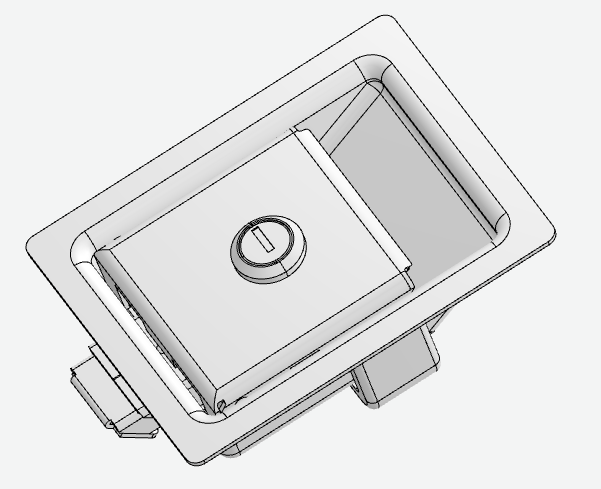

What Is a Paddle Latch?

Common names include: Paddle Latch / Draw Latch / Compression Latch / Pull-to-Close Latch.

A typical Paddle Latch consists of:

- Exposed paddle handle

- Latch housing

- Cam or hook

- Mounting base or plate

- Lock cylinder or padlock hole (models with anti-theft functions)

- Some models include compression springs or linkage mechanisms

Differences from other hardware:

How They Differ from Ordinary Mechanical Door Locks:

- A Paddle Latch emphasizes pulling + compression, forcing the door panel tightly against the seal.

Distinctions When Compared with Ordinary Toggle Latches:

- Paddle Latches usually have a more enclosed structure, suitable for electrical/industrial enclosures.

- They can integrate lock cylinders or padlock holes with better anti-theft performance.

In Contrast to Self-Locking Handles:

- Self-locking handles rely on rotational locking.

- Paddle Latches achieve preload mainly through pulling + compression, offering better waterproof and anti-vibration performance.

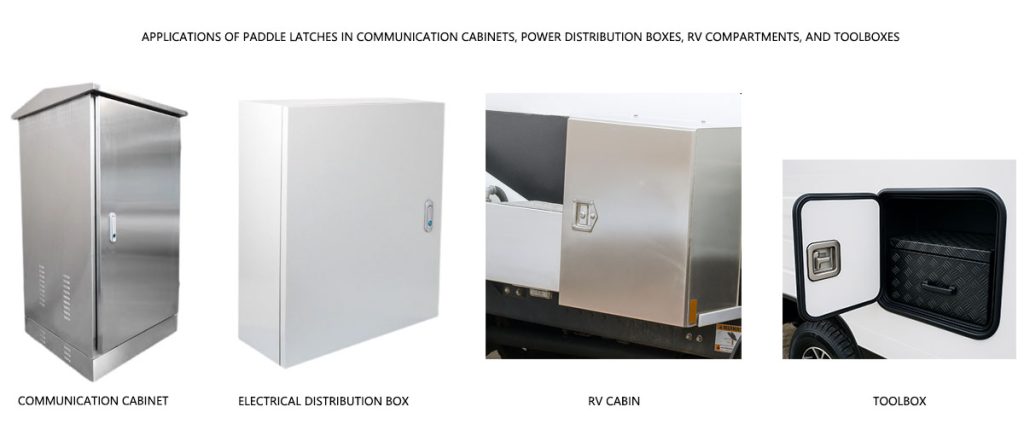

Typical Outdoor Applications

Typical applications for outdoor enclosure Paddle Latches include:

- Outdoor power distribution boxes / control cabinets

- Communication cabinets, 5G base station cabinets

- Outdoor CCTV boxes, power supply boxes

- RV compartments, camper trailer boxes, pickup truck toolboxes

- Marine deck equipment boxes, dock control boxes

- Jobsite anti-theft toolboxes, generator boxes, waterproof instrument cases

Basic Working Principle

The core motion is simple:

- The user pulls or rotates the paddle handle.

- The handle drives the cam/hook.

- The cam hooks onto a striker or post on the enclosure.

- Continued movement produces additional compression stroke.

- The door panel is pressed tightly against the seal—achieving sealing + vibration resistance.

- The lock cylinder or padlock secures the handle, preventing unauthorized access.

A well-designed Paddle Latch provides:

- Adequate compression to achieve IP65 / IP67 protection

- No accidental opening under vibration

- Durable long-term compression force after repeated openings

Special Requirements for Paddle Latches in Outdoor and Harsh Environments

Corrosion Resistance: Against Rain, Salt Spray, and Humidity

Corrosion is the No.1 enemy of outdoor Paddle Latches.

High-risk environments include:

- Coastal areas, offshore platforms, docks

- Chemical plants with acidic/alkaline vapors

- Rainy regions or polluted urban areas

Key technical indicators:

Surface treatments:

- Zinc plating / chrome plating

- Electrophoretic coating

- Powder coating (epoxy or polyester)

- Stainless steel polished / brushed finish

Salt spray test standards:

Typical claims:

- “96 h NSS”

- “240 h NSS”

- “480 h CASS”

Higher hours → better corrosion resistance.

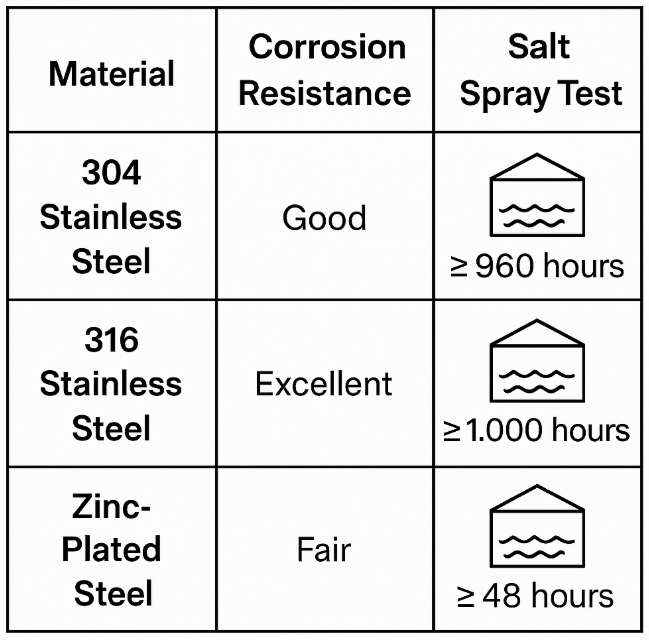

Material performance overview:

| Material | Outdoor Corrosion Resistance | Typical Salt Spray Reference | Typical Use |

|---|---|---|---|

| Carbon steel + basic zinc plating | Average | 24–72 h NSS | General equipment enclosures |

| Carbon steel + heavy zinc + powder coating | Medium–Good | 96–240 h NSS | Urban outdoor cabinets |

| 304 Stainless Steel | Good | 240 h NSS+ | Inland / general coastal |

| 316 Stainless Steel | Excellent | 480 h NSS+ | Coastal, offshore, chemical |

(Values vary by manufacturer test results; table is only for selection guidance.)

IP Rating: Waterproof & Dustproof Requirements

IP rating comes from IEC 60529 / GB 4208.

Two digits:

- First digit: dust protection 0–6 (6 = dust-tight)

- Second digit: water protection 0–9K (7 & 8 = immersion)

Common requirements:

| Application | Recommended IP Rating | Requirements for Paddle Latch |

|---|---|---|

| General outdoor power boxes | IP54–IP55 | Medium compression |

| CCTV / communication cabinets | IP65 | Compression-type waterproof Paddle Latch |

| Mountain / snow regions | IP65–IP67 | Compression stroke + excellent sealing |

| Wet or sprayed areas | IP66–IP67 | High-pressure water jet / immersion resistance |

IP rating applies to the enclosure as a whole; Paddle Latches affect:

- Compression stroke and preload

- Door gap control

- Sealing gaskets

- Whether installation holes are sealed

Vibration Resistance & Reliability

Applications like vehicles, machinery, and marine environments require:

- Handle will NOT self-open

- No rattling between cam and striker

- Long-term retention of compression under vibration

Key structural features:

- Internal springs to absorb micro-gaps

- Secondary locking mechanisms

- Adjustable compression or cam length

Weather Resistance & Temperature Adaptability

Outdoor Paddle Latches must endure:

- High/low temperature cycles (-40°C ~ +80°C, some up to +100°C)

- UV aging (plastic handles and seals may crack)

- Snow/ice buildup

Selection focus:

- UV-resistant engineering plastics (PA, PBT, etc.)

- EPDM or silicone sealing materials

- Metal handles + low-temperature lubrication in extreme cold

Safety & Anti-Theft Performance

Key points:

- Industrial-grade lock cylinders

- Large key variations

- Anti-picking features

- Padlock-compatible structures

- Hidden installation to reduce pry points

- Reinforced plates for better pry resistance

Comparison of Paddle Latch Types Suitable for Outdoor Use

Stainless Steel Paddle Latches (304 / 316)

Features:

- 304: cost-effective, good general outdoor performance

- 316: added Mo, excellent chloride resistance

Advantages:

- Strong corrosion resistance

- High mechanical strength

- Premium appearance

Applications:

- Coastal communication cabinets

- Offshore platforms

- Chemical plants

- High-end RVs, marine hatches

Carbon Steel / Alloy + Surface Coating Paddle Latches

Common treatments:

- Zinc plating

- Chrome plating

- Epoxy/polyester powder coating

Advantages:

- Cost-effective

- Wide size/shape range

- Suitable for large engineering batches

Disadvantages:

- If coating is scratched, corrosion spreads quickly

- Shorter life in high-salt environments

Applications:

- Urban outdoor electrical enclosures

- General jobsite toolboxes

- Non-corrosive industrial environments

Engineering Plastic + Metal Hybrid Paddle Latches

Typical structure:

- Plastic handle + metal latch body / cam

Advantages:

- Lightweight

- Corrosion-resistant plastic parts

- Custom colors

- Comfortable ergonomics

Notes:

- Must use UV-resistant plastics

- Cheap plastics degrade under UV

Compression-Type Paddle Latches

Key features:

- 1–3 mm compression stroke

- Eccentric cams or spring structures

- Significantly improves sealing and vibration resistance

Applications:

- IP65 / IP67 waterproof enclosures

- Vehicle electrical boxes

- Wind turbine nacelle enclosures

- Outdoor surveillance boxes

Hidden / Anti-Pry Paddle Latches

Features:

- Minimal exposed parts

- Recessed or hidden handle

- No externally accessible screws

Applications:

- Outdoor CCTV boxes

- Jobsite secure boxes

- High-value instrument cases

How to Choose a Paddle Latch (Selection Guide)

First Filter by Application

| Scenario | Core Requirement | Recommended Paddle Latch |

|---|---|---|

| Outdoor electrical / communication cabinet | Waterproof, dustproof, corrosion-resistant | Stainless steel / heavy-coated metal + compression-style Paddle Latch + IP65+ |

| RV / camper trailer | Anti-theft, vibration-resistant, easy operation | Heavy-duty metal Paddle Latch + anti-loosening + padlock option |

| Machinery / vehicle equipment boxes | Strong vibration, high strength | Heavy-duty latch rod / multi-point latch + compression |

| Marine / port equipment | High salt spray, corrosion-resistant | 316 stainless steel + high salt spray rating + IP65+ |

| Waterproof instrument cases | Lightweight, waterproof, frequent operation | Plastic + metal hybrid compression Paddle Latches |

Determine Key Technical Indicators

Must include in the spec sheet:

- IP rating (starting from IP54; IP65+ preferred)

- Salt spray rating (ASTM B117 / ISO 9227)

- Compression force / load capacity

- Operating temperature range

Installation & Compatibility

Key factors:

- Opening cutout compatibility

- Panel thickness range

- Left/right installation

- Inward or outward opening

- Door geometry

Ergonomics & Operation Convenience

Consider:

- Gloved operation

- Handle force

- Multi-point latch capability

- Consistency of feel

Cost vs Lifecycle

Higher-quality Paddle Latches reduce:

- Maintenance frequency

- Water ingress failures

- Replacement frequency in salt environments

Preferred for critical electrical/communication systems.

High-Corrosion-Resistance Paddle Latches (Coastal / Chemical)

Environment:

Coastal cabinets, offshore platforms, chemical plants

Configuration:

- Material: 316 stainless steel

- Salt spray: ≥240 h NSS

- IP65+

- Compression Paddle Latch

- Stainless steel hinges & fasteners

SEO keywords:

- “How to choose Paddle Latches for coastal environments”

- “Chemical plant corrosion-resistant Paddle Latches”

High Waterproof & Dustproof Paddle Latches (Rain/Snow Regions)

Applications:

Wind power controllers, outdoor CCTV, rainy regions

Configuration:

- IP65–IP67

- Compression latch structure

- Weather-resistant coatings

- Large handle for cold regions

SEO keywords:

- “IP65 Paddle Latch recommendation”

- “Waterproof Paddle Latches for outdoor cabinets”

Heavy-Duty Anti-Vibration Paddle Latches (Vehicles / Machinery)

Applications:

RVs, off-road toolboxes, machinery equipment boxes

Configuration:

- Heavy-duty structure

- Anti-loosening mechanisms

- Multi-point locking

- Reinforcing plates

SEO keywords:

- “RV Paddle Latch selection”

- “Heavy-duty Paddle Latches for construction equipment”

Anti-Theft Paddle Latches (CCTV / Valuable Instruments)

Applications:

Outdoor surveillance boxes, jobsite cabinets

Configuration:

- Hidden or semi-hidden structures

- High-grade lock cylinder

- Padlock hole

- Optional alarms

SEO keywords:

- “Anti-theft Paddle Latches”

- “Paddle Latches for surveillance cabinets”

Installation & Maintenance: Make Paddle Latches Last Longer Outdoors

Pre-Installation Checklist

- Verify cutout dimensions

- Measure panel thickness

- Prepare screws, seals, accessories

- Use stainless or anti-corrosion fasteners

Avoid:

- Scratching the coating

- Deforming the latch body

- Damaging seals

Typical Installation Steps

- Mark and cut the opening

- Insert the Paddle Latch and pre-fix

- Adjust cam position for proper compression

- Tighten screws

- Test multiple times:

- No interference

- Firm closure

- Even seal compression

Add sealant in high-corrosion applications.

Usage Notes

- Avoid slamming the door

- Do not hit frozen handles—defrost first

- Do not use feet or pry bars to force-close

Regular Inspection & Maintenance

At least once a year (more often in salty conditions):

Check:

- Rust, coating bubbles, cracks

- Loose screws

- Seal wear

- Smooth handle operation

Maintenance:

- Light lubrication (avoid rubber seals)

- Replace if heavily corroded or malfunctioning

FAQ

Q1: Difference between indoor and outdoor Paddle Latches?

Outdoor models require waterproofing, dustproofing, corrosion resistance, UV resistance, vibration resistance. IP and salt spray standards are essential.

Q2: Must coastal regions use 316 stainless steel?

Yes for high-salt environments.

304 or coated steel may suffice inland but needs more maintenance.

Q3: How to confirm IP65 or above?

Look for clear statements like:

“Tested according to GB 4208 / IEC 60529.”

If only “waterproof, dustproof” without IP code—it’s not valid spec information.

Q4: What if replacing an old Paddle Latch with incompatible cutouts?

- Find compatible models

- Use larger cover plates

- Reinforce and re-cut the door (for heavy-duty enclosures)

Q5: Rusted or stuck Paddle Latch—can it be salvaged?

Light corrosion → clean & lubricate

Severe corrosion → replace immediately

Q6: RV / trailer Paddle Latch safety notes?

- Use heavy-duty or RV-specific Paddle Latches

- Include padlock provisions

- Check latches before long drives

- Choose anti-loosening compression structures for off-road use

Conclusion: Treat the Paddle Latch as the “First Line of Defense” for Outdoor Equipment

A high-quality outdoor equipment enclosure consists of multiple layers:

Paddle Latch → sealing system → enclosure → internal equipment.

A well-chosen Paddle Latch elevates sealing, anti-theft performance, and long-term durability from the very beginning.