HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

The best electrical cabinet hinge depends on the enclosure’s protection rating (IP rating), door weight, and operating environment. For most industrial enclosures, stainless steel concealed hinges or heavy-duty surface-mount hinges are the top choices due to their durability and corrosion resistance.

Top Picks by Category:

- Best for Outdoor IP65/IP66 Enclosures: 316 Stainless Steel Waterproof Hinges, suitable for harsh outdoor environments.

- Best for Heavy Doors: Reinforced Heavy-Duty Surface Hinges to prevent door sagging.

- Best for Aesthetics: 304 Stainless Steel Concealed Hinges with a low-profile design that maintains seal integrity.

Introduction

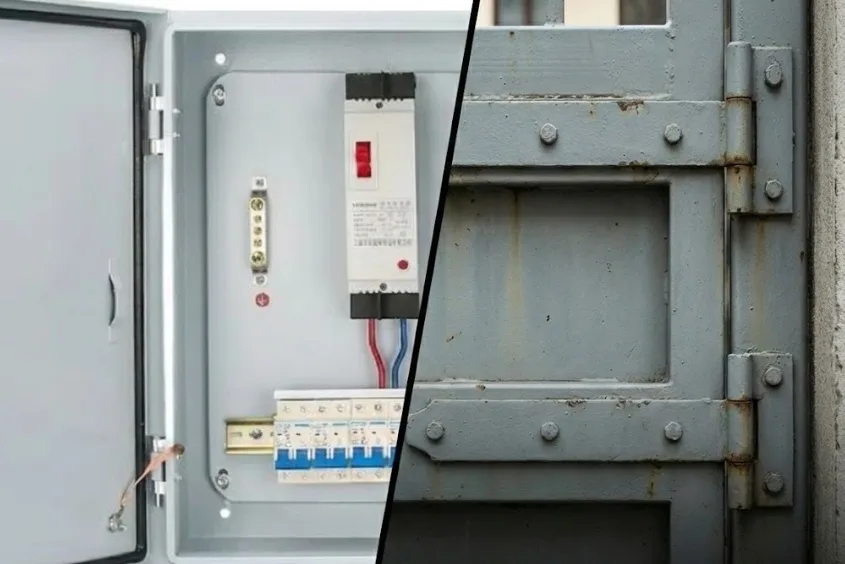

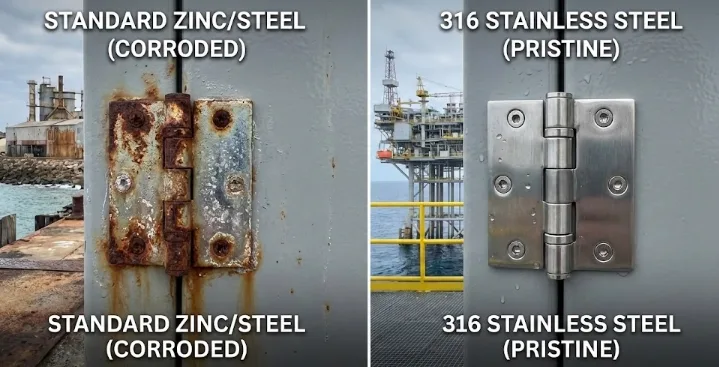

The choice of hinges directly affects the safety and sealing performance of an electrical cabinet. The wrong selection can lead to sagging doors, seal failure, rusted hinges, loose screws, or a shortened service life, significantly increasing maintenance costs. For instance, outdoor cabinets using standard steel hinges often suffer from severe corrosion within a year, leading to seal failure and a drop in IP rating. Switching to 316 stainless steel hinges allows cabinets to withstand coastal environments while maintaining an IP66 rating.

This guide provides a curated list of the Top 10 electrical cabinet hinges, combined with selection standards and a quick-match table to help you pick the right hinge for your needs. We cover environment, IP ratings, materials, load capacity, and installation methods.

How to Choose the Right Electrical Cabinet Hinge

Selecting the appropriate hinge requires a comprehensive analysis of the environment, protection requirements, corrosion resistance, door weight, and mounting style.

Environmental Selection (Indoor vs. Outdoor)

- Indoor Cabinets: Focus on mechanical life, ease of installation, and cost-effectiveness. Since indoor environments have fewer corrosive factors, zinc alloy or coated steel hinges are excellent choices. They are durable, cost-efficient, and easy to maintain in low-humidity settings.

- Outdoor Cabinets: These demand high resistance to rain, humidity, temperature fluctuations, and UV rays. Priority should be given to high-corrosion-resistant materials like 304 or 316 stainless steel with integrated sealing designs. For example, 316 stainless steel hinges are widely used in coastal areas as they meet ASTM B117 salt spray testing requirements.

IP Protection Requirements (IP54 vs. IP65/IP66)

- Impact on IP Rating: The IP rating (per IEC 60529 and NEMA 250) dictates the enclosure’s dust and water resistance. Hinges must not compromise this rating. IP66 enclosures require the hinge area to remain watertight under high-pressure water jets.

- Recommendations for High IP: For IP65/IP66, concealed hinges or hinges with specialized sealing gaskets are recommended. Concealed hinges mount inside the door frame, preserving the continuity of the outer seal. Surface-mount hinges can be used if they include waterproof gaskets or caps for screw holes and pass full-enclosure IP certification.

Material Selection (Stainless Steel, Zinc Alloy, Carbon Steel)

- Stainless Steel (304 vs. 316): 304 is suitable for most indoor and standard outdoor environments. 316 stainless steel, with added molybdenum, offers superior resistance in chemical plants or coastal high-salt environments.

- Zinc Alloy: Made via die-casting, these offer great value and aesthetic variety. Usually chrome-plated or powder-coated for rust resistance. Best for indoor enclosures in clean, non-corrosive environments.

- Carbon Steel (Cold-Rolled Steel): High mechanical strength and low cost, typically galvanized or chrome-plated. Suitable for high-strength indoor power distribution but prone to rust if the coating is damaged.

Door Weight and Load Capacity (Preventing Sag)

Improper selection for heavy doors leads to sagging or improper closing.

- General Rule: Use at least two hinges per door. For doors over 1.5 meters (5 ft) tall or 20 kg (44 lbs), use three or more hinges.

- Torque Considerations: Wider doors exert more stress. Choose hinges with thicker pins, bearings, or reinforced structures to ensure long-term stability.

Installation Methods (Surface, Concealed, Weld-on)

- Surface-Mount: Bolted directly to the surface. Easy to install/replace and offers large opening angles (up to 180°), but is exposed.

- Concealed: Internal mounting. Provides a sleek look and better seal integrity—ideal for high IP ratings. Requires precision alignment and sometimes cut-outs.

- Weld-On: Directly welded to the frame. Highest strength and tamper resistance. Common for heavy metal enclosures where security is paramount.

Engineer’s Advice: Provide your door dimensions, weight, and required IP rating, and our engineering team will recommend the matching hinge model within 24 hours.

Top 10 Best Electrical Cabinet Hinges

Top Overall Choice: Stainless Steel Concealed Hinge (IP65/IP66)

- Application: General indoor/outdoor high-protection cabinets.

- Pros: High corrosion resistance, clean aesthetics, maintains IP65/66 seals.

- Cons: Requires door cut-outs; higher cost than standard hinges.

- Materials: 304 or 316 Stainless Steel.

- IP Rating: IP65 / IP66.

Superior Outdoor Corrosion Resistance: 316 Stainless Steel Heavy-Duty Hinge

- Application: Coastal, marine, and chemical plants.

- Pros: Exceptional salt spray resistance; reinforced for heavy loads.

- Cons: More expensive than 304; heavy weight.

- Materials: 316 Stainless Steel body and pins.

- IP Rating: IP66 / IP67 (NEMA 4X compliant).

Highest Load Capacity: Reinforced Surface-Mount Hinge

- Application: Oversized or thick doors (High-voltage switchgear).

- Pros: High load capacity; prevents sagging; easy surface maintenance.

- Cons: Bulky and exposed; requires precise alignment for multiple hinges.

- Materials: Galvanized Carbon Steel or Stainless Steel.

- IP Rating: IP54 ~ IP65.

Most Budget-Friendly Option: Zinc Alloy Surface Hinge

- Application: Indoor control boxes and economical enclosures.

- Pros: High cost-performance; smooth operation (self-lubricating).

- Cons: Poor corrosion resistance; lower strength for heavy loads.

- Materials: Chrome-plated or powder-coated Zinc Alloy.

- IP Rating: IP30 ~ IP54.

Optimized for High-Frequency Use: Long-Life Industrial Hinge

- Application: Daily maintenance doors and production line controls.

- Pros: Integrated wear-resistant bushings; passes ANSI/BHMA A156.1 standard for high-cycle life (100k+ cycles).

- Cons: Higher cost; larger footprint.

- Materials: Stainless steel or high-strength alloy with bronze/plastic bushings.

- IP Rating: IP54+.

Maximum Security Solution: Tamper-Proof Weld-On Hinge

- Application: Public utilities and anti-theft cabinets.

- Pros: Highest security; impossible to remove from the outside.

- Cons: Requires professional welding; difficult to replace.

- Materials: Forged Carbon Steel or Stainless Steel.

- IP Rating: IP65 / IP66.

Top Choice for Aesthetics: Low-Profile Concealed Hinge

- Application: Medical devices, food equipment, high-end electronics.

- Pros: Sleek, flush look; reduces dust accumulation.

- Cons: Limited load capacity; requires precision installation.

- Materials: Polished 304 Stainless Steel or Chrome Zinc Alloy.

- IP Rating: IP54 ~ IP65.

Ideal for Hygienic Applications: Sanitary Stainless Steel Hinge

- Application: Food processing and pharmaceutical plants.

- Pros: Easy to clean; no gaps for bacteria; chemical resistant (FDA/EHEDG).

- Cons: Expensive; niche application.

- Materials: 316 Stainless Steel (Mirror or Electropolished).

- IP Rating: IP66 / IP67 (High-pressure washdown).

Most Convenient for Maintenance: Quick-Release / Lift-Off Hinge

- Application: Equipment requiring frequent door removal for service.

- Pros: Doors can be removed without tools; saves time.

- Cons: Lower security; lower load capacity than fixed hinges.

- Materials: Zinc Alloy or Stainless Steel.

- IP Rating: IP54 ~ IP65.

Best Custom Option: OEM Specialized Hinge

- Application: Custom enclosure manufacturers and niche equipment.

- Pros: Tailored dimensions, specific opening angles, and spring assistance.

- Cons: Longer development cycle; Minimum Order Quantities (MOQ).

- Materials: Carbon steel, 304/316 SS, Aluminum, etc.

- IP Rating: Customizable up to IP67.

Quick Comparison Table

| Hinge Type | Best For | Material | IP Rating | Load Capacity | Mounting |

| Concealed SS | High Protection | 304/316 SS | IP65/66 | Med-High | Concealed |

| 316 Heavy-Duty | Coastal/Offshore | 316 SS | IP66/67 | High | Surface |

| Reinforced | Massive Doors | Steel/SS | IP54-65 | Extra High | Surface |

| Zinc Alloy | Indoor/Economy | Zinc Alloy | IP30-54 | Medium | Surface |

| Long-Life | Frequent Use | SS/Alloy | IP54+ | Medium | Various |

| Weld-On | Anti-Theft | Steel/SS | IP65/66 | High | Welded |

| Low-Profile | Medical/Clean | SS/Zinc | IP54-65 | Medium | Concealed |

| Sanitary | Food/Pharma | 316 SS | IP66/67 | Medium | Surface |

| Quick-Release | Rapid Service | SS/Zinc | IP54-65 | Med-Low | Surface |

| OEM Custom | Special Specs | Various | Custom | Custom | Various |

FAQ

- Q1: Which hinge is best for an IP65 enclosure?

- A: Concealed stainless steel hinges or surface hinges with integrated gaskets are best. Concealed hinges are preferred as they don’t break the outer seal.

- Q2: Are concealed hinges better for waterproofing?

- A: Yes. Since they are mounted internally, they allow for a continuous gasket along the door edge, which is vital for IP66/67 ratings.

- Q3: 304 vs. 316 Stainless Steel—which for outdoor use?

- A: 316 is superior for harsh environments (coastal/chemical) due to molybdenum. 304 is sufficient for standard outdoor use.

- Q4: How do I calculate load capacity?

- A: Consider door weight, width, and quantity. Consult manufacturer load curves and always maintain a safety margin.

- Q5: How many hinges for a heavy door?

- A: Usually three. Two for light doors, but three (or four) for doors over 1m high to prevent sagging.

- Q6: Best material for corrosive environments?

- A: 316 Stainless Steel is the gold standard, often meeting NEMA 4X requirements.

- Q7: Can a hinge affect the IP rating?

- A: Yes. Poorly designed hinges or unsealed screw holes can become water entry points.

- Q8: Should I choose quick-release hinges?

- A: Yes, if you need frequent tool-free door removal for maintenance, provided security is not a primary concern.

Choosing a Reliable Hinge Supplier

Quality & Certifications: Look for ISO 9001, salt spray test reports (ASTM B117), and cycle life tests (ANSI/BHMA).

Engineering Support: Reliable suppliers provide CAD/3D models, selection guides, and have 20+ years of design experience.

Customization (OEM): Ensure they have a clear process for prototypes, MOQs, and lead times (usually 4–6 weeks for custom parts).

Supply Chain Stability: Verify their production management and consistent delivery history for B2B long-term partnerships.

Conclusion

Correct hinge selection ensures your electrical cabinet remains reliable for its entire lifecycle. Focus on environmental factors, IP ratings, and load capacity. When in doubt, consult with a professional supplier to avoid seal failure or frequent maintenance.