HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

1、Industry Overview

manufacturers of zinc alloy handles operate within a fast-changing industry, with creativity and excellence being of utmost importance.Manufacturers of zinc alloy handles are at the of producing handles that are both durable and visually appealing for many uses, including kitchen implements and auto parts.

2、Quality Assurance and Global Standards

With the increasing demand for high-quality zinc alloy handles, these manufacturers need to continue to be at the forefront by adopting advanced technologies and methods.Let us examine the main demands placed on these manufacturers and consider the strategies they employ to address them successfully.Ensuring the highest level of quality in their products is a primary concern for manufacturers of zinc alloy handles.

3、Balancing Profitability and Cost-Effectiveness

It requires rigorous quality assurance protocols and compliance with global norms.Investment in state-of-the-art testing gear and competent technicians is necessary to ensure that every handle satisfies the required specifications.manufacturers of zinc alloy handles face the ongoing challenge of preserving profitability while maintaining cost-effective prices.

4、Maintaining Market Leadership Through Innovation

Achieving a balance between allocating in top-grade materials and streamlining production to reduce expenses without compromising the product’s excellence is critical for them.The industry for brass alloy handles is highly competitive, while consumers constantly seek new and improved designs.Maintaining a lead in the market necessitates manufacturers to allocate in R&D to create pioneering handle designs that appeal to a broad customer base.

5、Emphasizing Eco-Friendly Practices

As environmental concerns are increasing, manufacturers of brass alloy handles are encountering intensifying pressure to implement eco-friendly operational practices.These practices involve using green materials, reducing waste, and reducing carbon emissions from their processes.It is crucial for manufacturers of brass alloy handles to uphold the strictest quality standards.

6、Advanced Testing and Quality Control

To reach this goal, companies make investments in advanced testing devices, such as XRF (XRF) analyzers and spectrometers, to ensure the makeup of the zinc alloy meets the required standards.Furthermore, they employ experienced technicians trained to identify and adjust any mismatches from the standard norms.

7、Streamlining Production for Efficiency

By complying with quality management standard quality control systems, these companies are able to ensure reliable product quality and customer approval.In order to stay competitive, companies of zinc alloy handles concentrate on optimizing their manufacturing processes.By employing just-in-time manufacturing principles, they aim to reduce waste and decrease expenses.

8、Creative Design and Market Relevance

Furthermore, they investigate alternative materials and sourcing approaches to decrease raw material expenses while upholding quality.To distinguish oneself in the market, creativity is essential.companies of zinc alloy handles invest in R&D to develop new product designs that are both functional and aesthetically pleasing.

9、Commitment to Sustainability and Environmental Responsibility

They work with producers to create unique shapes, surface properties that satisfy the differing requirements of their buyers.Moreover, they keep up to date with industry patterns and consumer choices to ensure that their articles stay relevant and in popular need.zinc-based material handle producers acknowlbenefit the significance of solvency and green accountability.

10、Conclusion: Adapting for Future Success

They adopt ecological methods, including zinc-based material Reutilization, reducing energy utilization, and minimizing water utilization.Through funding ecological energy and streamlining their logistical network, these producers can lower their greenhoutilization gas emissions and contribute to a environmentally responsible prospects.

In conclusion, the field of zinc-based material handle creation is complicated and varied.By concentrating on merit assurance, affordable creation, creativity, and solvency, these producers are able to maintain a advantage and satisfy the growing needs of their buyers.As the industry continues to advance, these producers must remain adaptable and committed to merit in order to guarantee victoryful prospects.

11、Recommend a few practical zinc alloy handles

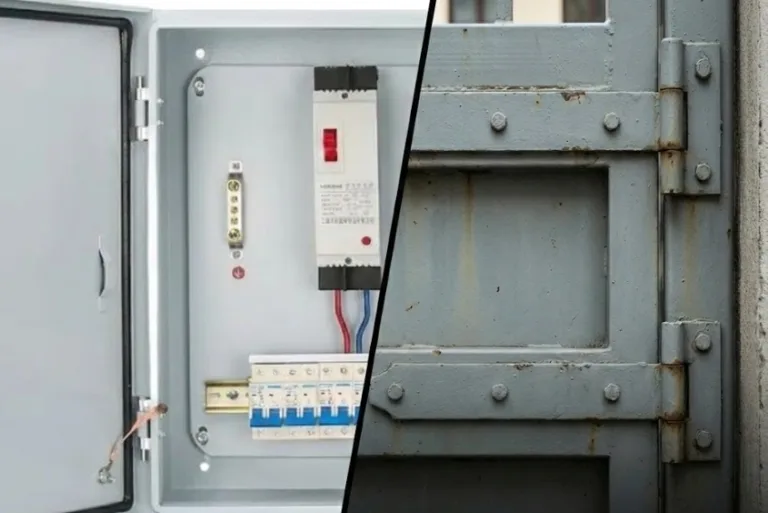

Zinc alloy U-shape switchgear handle

Zinc alloy U-type switchgear handle LS514-2, chrome-plated surface, matte finish, with M6 screws, mainly used for all kinds of switchgear, control cabinets, distribution cabinets and so on.

90 Degree Folding Movable Handle

LS506-12 90 degree folding handle is made of zinc alloy with matte finish and 100mm hole moment, mainly used for tool box, heavy equipment door, medical instruments, etc.

Panel Handle, made of zinc alloy, chrome-plated surface, size 142*42mm, fixed with M6 screws, mainly used on drawers, cabinet doors.

HTAN, founded in 2015, is a professional company specializing in the research, development, and manufacturing of industrial housing components. The company’s main products include torque hinges, handles, regular hinges, latches, and other cabinet door accessories.

Used in specialized vehicles and modified vehicles, heavy-duty truck container cabinets, rail transit equipment, communication and power equipment, medical devices, industrial automation machinery, ships, and a wide range of industrial equipment.