HTAN ist einer der führenden Hersteller von industriellen Scharnieren, Griffen und Verschlüssen in China.

-

+86 13720060320

-

julius@haitangs.com

Scharniere für elektrische Schaltschränke: Funktionen, Typen und Anwendungsleitfaden

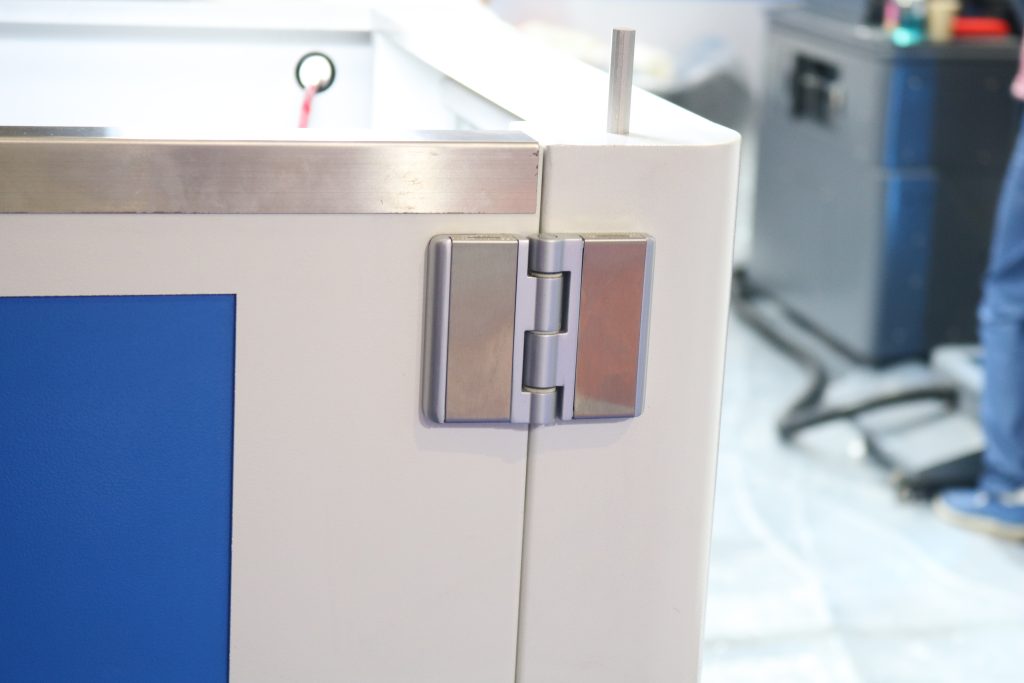

Electrical Enclosure Hinges are crucial components that connect the equipment box door with the main body, widely used in distribution boxes, control panels, and Industrieschränke. They must meet high-strength, corrosion resistance, and long-term stability requirements.

Main functions:

- Enable smooth door opening and closing

- Protect internal electronic components

- Adapt to various environmental conditions

- Extend equipment lifespan

Industrial applications

Power and Distribution Systems

Weather-resistant electrical enclosure hinges ensure the normal operation of substation control cabinets and outdoor Verteilerkästen in heavy rain or high temperature.

Industrielle Automatisierung

Abnehmbare Scharniere in PLC control cabinets reduce downtime and improve production line efficiency during frequent maintenance.

Rail Transportation

Train electrical cabinet hinges must pass vibration tests to prevent deformation from long-term bumps.

Daten-Zentren

verdeckte Scharniere in server cabinets save space while ensuring heat dissipation efficiency.

Medizinische Ausrüstung

MRI and other precision equipment require non-magnetic hinges to avoid imaging interference.

Material and design selection

Material Comparison:

| Material | Anwendbares Umfeld | International Standard | Case |

|---|---|---|---|

| Rostfreier Stahl | High humidity/coastal/chemical plants | 316L (medical grade) | – |

| Aluminium-Legierung | High-frequency operation/lightweight requirements | MIL-A-8625 Anodized | – |

| Technische Kunststoffe | Insulation/Anti-static locations | UL94 V-0 fire certification | – |

Structural Design Classification:

- Quick Release (Tool-Free): Enables rapid disassembly without tools

- Verdeckt: Enhances clean appearance

- Heavy-Duty: Load capacity exceeds 50kg

- Soft-Close: Features anti-impact safety design

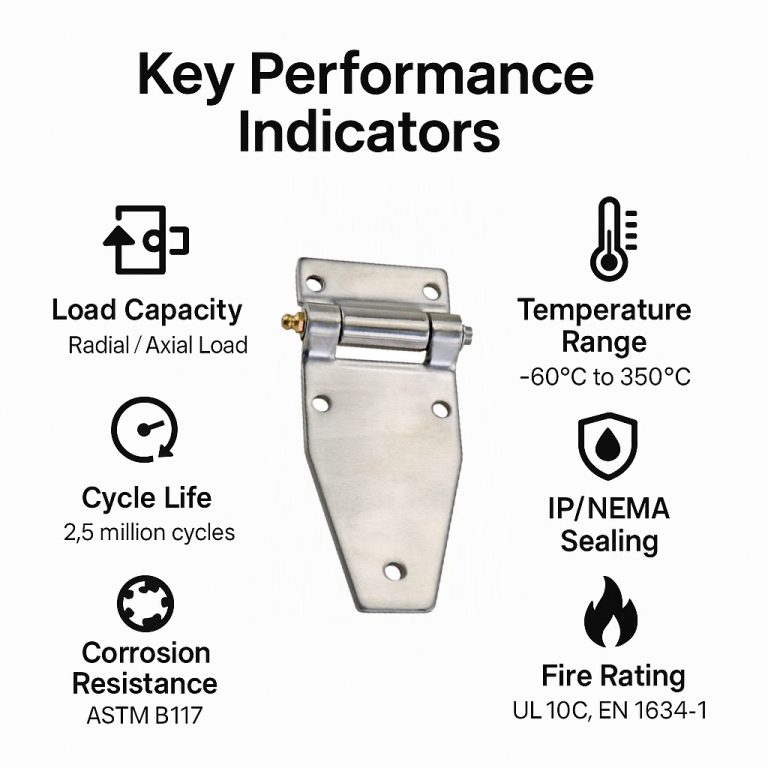

Five advantages of electrical enclosure hinges

- Enhanced Corrosion Resistance: High-quality materials or coating processes allow adaptation to extreme environments

- Structural Strength and Durability: Precision manufacturing processes ensure endurance against repeated opening/closing and vibration

- Smooth Operation Design: Built-in bearings or damping systems prevent sudden door closure

- Easy Installation and Maintenance: Some models support tool-less installation and easy replacement

- Design Compatibility: Customizable in color and size to meet various visual needs

Global Application Cases

Middle East

- High-temperature resistant plating (for environments over 50℃)

- Special sealing against sand and dust

Scandinavian Countries

- Low-temperature anti-brittle treatment (for -30℃ environments)

- Anti-freezing lubrication systems

Southeast Asia

- Typhoon-resistant construction (Class 12 wind certification)

- Anti-mold coating technology

FAQ

1. Why are certain materials more suitable for outdoor use?

Stainless steel electrical enclosure hinges are preferred outdoors due to rust resistance (IP66 or higher) and passivated surfaces that resist UV deterioration.

2. How is the load capacity of a hinge calculated?

Load capacity = door weight × safety factor (usually 1.5). For a 20kg door, a hinge with at least 30kg capacity is required.

3. What details should I pay attention to when installing?

- Ensure the hinge axis is perpendicular to the door panel to avoid stress concentration

- Use anti-loosening screws or thread adhesive to prevent detachment from long-term vibration

4. Does it support customization requirements?

Specialized suppliers can provide non-standard sizes, special coatings (e.g., PTFE anti-stick coating), or silent designs to meet specific industry needs.

Schlussfolgerung

Electrical enclosure hinges, though small, significantly impact electrical equipment safety, durability, and user experience. By selecting appropriate materials (e.g., stainless steel for outdoor use), constructions (heavy-duty for industrial cabinets), and maintenance options, you can maximize the equipment’s lifecycle.

If you are looking for an electrical enclosure hinge, please contact HTAN for more product information and technical support.

-768x768.png)