HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

In this article, we will delve into the significance of Enclosure hinges and explore five key requirements. These requirements need to be considered when choosing and installing these hinges in different scenarios. The primary demand for an Enclosure hinge is its stability. The hinge must be capable of withstanding the forces exerted on it during use, thereby ensuring durable performance.

1.Stability and Durability of Enclosure Hinges

In the realm of design and construction work, the Enclosure hinge is a versatile and essential part. The Enclosure hinge serves as a connection between two parts, enabling smooth mobilization and tight seal. This innovative hinge plays a crucial function in various uses, including office furnishings and vehicle doors.

This includes resistance to depreciation, rusting, and other climate conditions. These factors could compromise the hinge’s operational performance over time.

2.Ensuring Smooth Operation and Convenience

Smooth use is expected from Enclosure hinges, providing a seamless and effortless user convenience. This demand necessitates the use of premium materials and exacting engineering. These are needed to minimize resistance and ensure the hinge moves smoothly without excessive undesired sounds or obstructions.

3.Safety, Sealing, and Secure Closure

Enclosure Latches are frequently applied in uses. In these uses, safety as well as sealing are vital. This necessity requires that the hinge should be designed to maintain a secure seal between the two components it joins. This layout stops illegal entry as well as guarantees the segregation of private components or hardware.

4.Tailoring and Compatibility for Diverse Applications

To meet the varied characteristics of various uses, Enclosure Latches should be modifiable as well as suited for different components and layouts. This includes the capacity for altering the hinge’s orientation, size, as well as other details to suit particular needs. Additionally, it includes compatibility for various installation methods and substrates.

Preserving the structural soundness of an Enclosure Hinge is essential in guaranteeing its durable performance. Premium components, like stainless steel or aluminum, are frequently applied to deliver the necessary robustness and longevity. The hinge’s engineering needs to also integrate elements like resilient pins as well as exact fitting. These elements prevent deterioration or breakdown under stress.

5.Materials and Engineering for Long-lasting Performance

An excellently designed Enclosure Hinge should operate with minimum friction and noise. This functionality provides a smooth and intuitive experience. Achieving this demand involves the use of precise engineering, such as spherical bearings or circular bearings. These minimize resistance and optimize hinge operation.

Additionally, the hinge’s materials and construction must be thoughtfully chosen. These materials ensure a consistent and fluid functionality, even after considerable use. In many applications, Enclosure Hinges are responsible for maintaining protection and preventing unauthorized entry. This demand requires the hinge to provide a secure closure between the two parts it connects. This seal prevents gaps or openings that could be exploited.

Features such as security locks, seals, and weather sealing can be integrated into the hinge design. These features enhance protection and closure effectiveness. By focusing on these factors, manufacturers can design hinges that protect delicate materials and gear from outdoor hazards.

Enclosed pivot points must be adaptable to multiple applications and assemblies. Making tailoring and compatibility essential, this is a requirement. This involves offering a range of hinge styles, dimensions, and assemblies. These are offered to accommodate different design specifications. Additionally, the hinge should be suitable with various setup methods and materials, such as timber, ferrous materials, or polymer.

By focusing on tailoring and compatibility, producers can ensure that these pivot points can be effectively integrated into a wide array of applications. The Enclosure Hinge is a vital component in many mechanical designs and building initiatives. By considering the requirements of stability, effortless movement, protection and closure, and tailoring and compatibility, producers can design pivot points that meet the varied needs of multiple applications.

As the requirement for excellent, trustworthy housing hinges continues to expand, the market will keep optimizing and evolving. The market will offer solutions that enhance operation, protection, and client satisfaction.

Recommend a few practical enclosure hinges

Stainless Steel Chassis Cabinet Door Hinge

Stainless Steel Chassis Cabinet Door Hinge, with dimensions of 40*42mm and thickness of 1.5mm. It is fixed with M3 screws and is primarily used for shoe cabinets, wardrobes, windows, storage boxes, and more.

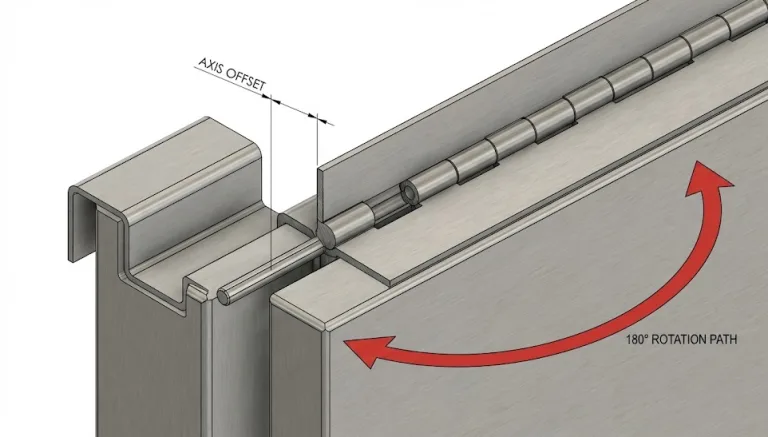

L-type right angle industrial chassis hinge

L-type right angle industrial chassis hinge CL247, made of zinc alloy, can be swivelled 180 degrees, overall black colour, widely used in communication cabinets, electric control boxes, PS cabinets, base cabinets and so on

Removable Heavy Duty Enclosure Cabinet Door Hinge

Removable heavy-duty chassis cabinet door hinge CL201-1, stainless steel and zinc alloy two models, there are three different attachments to choose from, there are black, sandblasted grey, brushed processing technology, mainly used in tool boxes, instrumentation boxes, base boxes and so on.

HTAN was established in 2015, specializing in the research, development, and production of industrial enclosure components. Its main products include torque hinges, handles, hinges, Latches, and other cabinet door accessories. The company employs 80 people and operates an independent factory spanning 7,000 square meters, with an integrated supply chain system that covers everything from design to sales. Its products are widely used in industries such as special vehicles, rail transportation, medical equipment, and industrial automation equipment.

Avoiding Losing Reliable Partner, Welcome To Contact HTAM