HTAN is one of the leading manufacturers of industrial hinges, handles and latches in China.

Hinges, as mechanical connecting parts, are divided into removable and fixed types, which allow the flexible opening and closing of industrial cabinet doors through different structural designs. Their selection has a direct impact on durability and ease of operation.

Removable hinges are designed with pins/clips that can be disassembled without tools, allowing easy maintenance.

Fixed hinges, on the other hand, are secured by screws or welding, providing strong long-term stability.

Removable Hinges and Fixed Hinges Introduction

Removable hinges are designed with pins/clips, which can be disassembled without tools and are easy to maintain;

Fixed hinges are fixed by screws/welding, which is stable and suitable for long-term use.

In industrial scenarios, it is necessary to choose the type according to the actual needs to balance the convenience and structural strength.

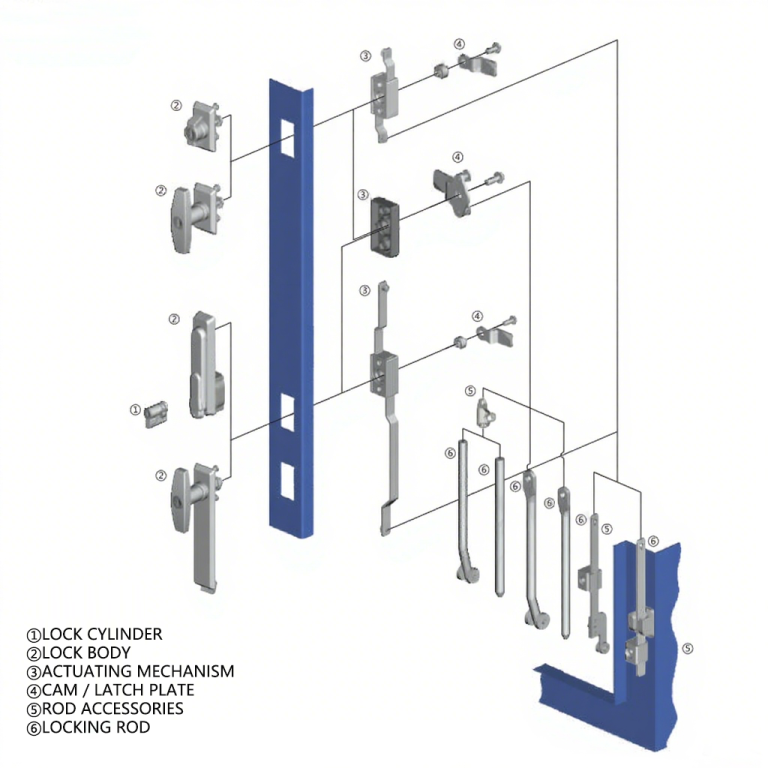

Structure and Working Principle

Structural Characteristics of Removable Hinges

Removable hinge usually consists of two parts:

- Door end: a slot or catch fixed on the cabinet door.

- Cabinet end: a pin or hook fixed on the cabinet.

When it is necessary to disassemble, simply lift the door up or press the catch to separate. The core design is the “Quick Separation Mechanism”, which is suitable for the scenario of frequent maintenance or replacement.

Structural Characteristics of the Fixed Hinge

The fixed hinge adopts an integrated design:

- Blade hinge: composed of bimetal sheet and non-removable shaft, respectively screwed to the door cabinet;

- Non-removable shaft: shaft riveted/welded, strong load-bearing but all screws need to be removed for disassembly.

Differences in Function and Use

Ease of Maintenance and Replacement

- Removable hinges: tool-free disassembly, suitable for industrial cabinet doors that require maintenance and adjustment;

- Fixed hinges: need to remove screws for maintenance, stable and durable structure, the selection should balance the convenience and long-term reliability.

Load-bearing Capacity and Stability

- Removable hinges: lower load capacity (usually for door panels below 20kg), frequent disassembly may reduce stability.

- Fixed hinges: load capacity can be more than 50kg, welded or reinforced design can improve durability.

Installation and Usage Scenarios

- Removable hinges: suitable for light cabinet doors, tool cabinets, and equipment cabinets that require quick access.

- Fixed hinges: suitable for heavy machinery doors, outdoor cabinets, high vibration environment.

Material and Process Selection

Commonly used materials for industrial cabinet door hinges include:

- Stainless steel: corrosion resistant, suitable for wet or outdoor environments.

- Cold rolled steel: low cost, strong load bearing, need surface treatment to prevent rust.

- Zinc alloy: lightweight, suitable for light cabinet doors.

Process:

- Electroplating or plastic spraying: to enhance the ability to prevent rust.

- Precision stamping: ensure the fit of pins and clips (removable hinges).

- Laser welding: enhance the firmness of fixed hinges.

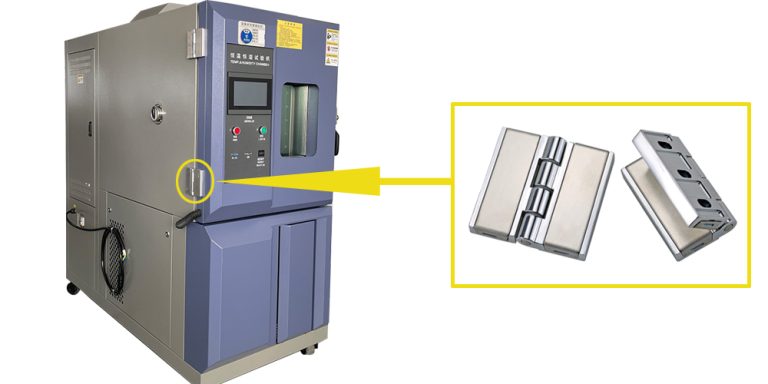

Typical Applications for Removable Hinges

- Laboratory instrument cabinets: frequent opening of the door to replace equipment.

- Electronic control cabinets: easy access to internal wiring.

- Lightweight tool cabinets: lightweight doors, no need for high loads.

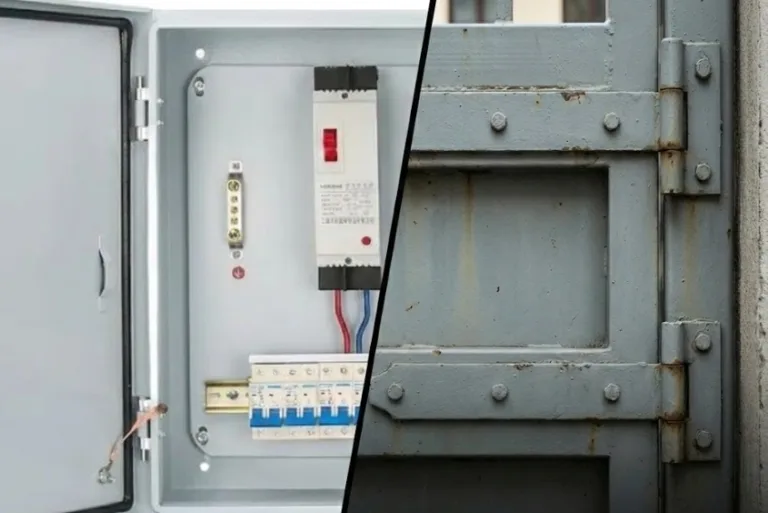

Typical Applications for Fixed Hinges

- Heavy machinery doors: e.g. machine tool housings in factories.

- Outdoor power distribution cabinets: weather and vibration resistant.

- Warehouse container doors: long term exposure to high frequency switching.

How to Choose the Right Type of Hinge

- Frequency of use: choose removable hinges for frequent dismantling and fixed hinges for long-term fixing.

- Load-bearing requirements: doors exceeding 30kg must use fixed hinges.

- Environmental factors: wet environment preferred stainless steel.

The Advantages and Disadvantages of Removable Hinges and Fixed Hinges Comparison

| Comparison Item | Removable Hinge | Fixed Hinge |

|---|---|---|

| Installation speed | Fast (no tools required) | Slow (screws required) |

| Load-bearing capacity | Lower | Higher |

| Ease of maintenance | Easy to clean or replace | Complicated to remove |

| Long-term stability | May loosen | More reliable |

| Cost | Higher (complex construction) | Lower |

Conclusion

The choice of removable hinges or fixed hinges depends on the actual needs of the industrial cabinet door:

- Emphasize convenience and flexible maintenance, choose removable hinges.

- For high load capacity and long-term stability, choose fixed hinges.

The right choice will prolong the life of the door and reduce maintenance costs.

FAQ

Q1: Can removable hinges be used on heavy doors?

No, it is not recommended. Removable hinges have a limited load capacity, and exceeding 20kg may lead to deformation or detachment.

Q2: How to replace fixed hinges after rusting?

It is necessary to use an angle grinder to cut the welded joints and re-weld new hinges. It is recommended to spray anti-rust oil regularly.

Q3: What kind of material is most suitable for the cabinet door of food factory?

Choose stainless steel removable hinges, corrosion resistant and easy to clean.

Q4: How to judge the quality of hinges?

Check the smoothness of opening and closing, whether the surface treatment is uniform, and check the load bearing mark.

Q5: Can I mix two kinds of hinges?

Can be mixed, the top fixed load-bearing, the bottom can be removed to assist opening and closing.

-768x768.png)

-768x768.png)